A multi-effect synchronous continuous treatment equipment for textile waste gas flocculent fiber

A processing equipment and synchronous technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as harm to human health, blockage of filter equipment, air pollution, etc., achieve continuous and efficient purification process, and ensure effective adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

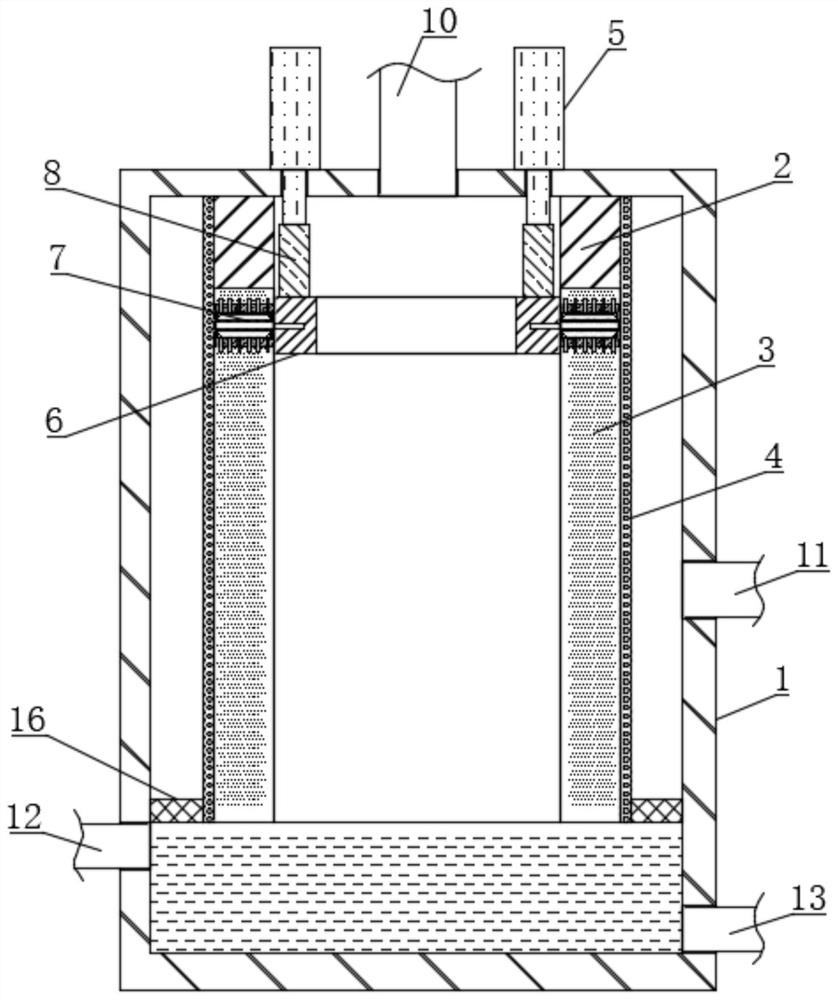

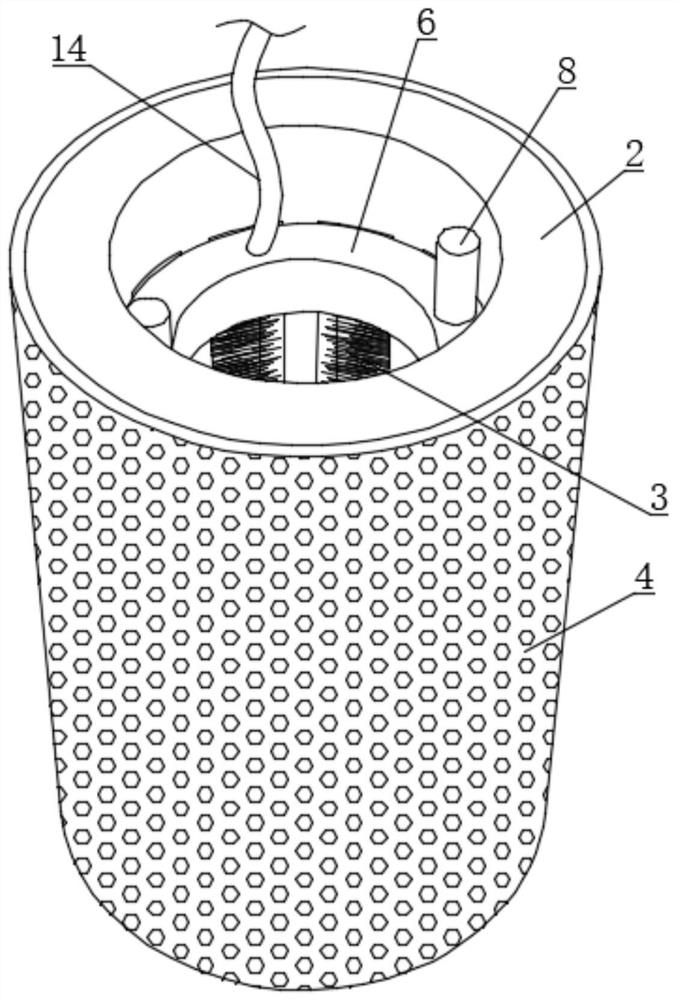

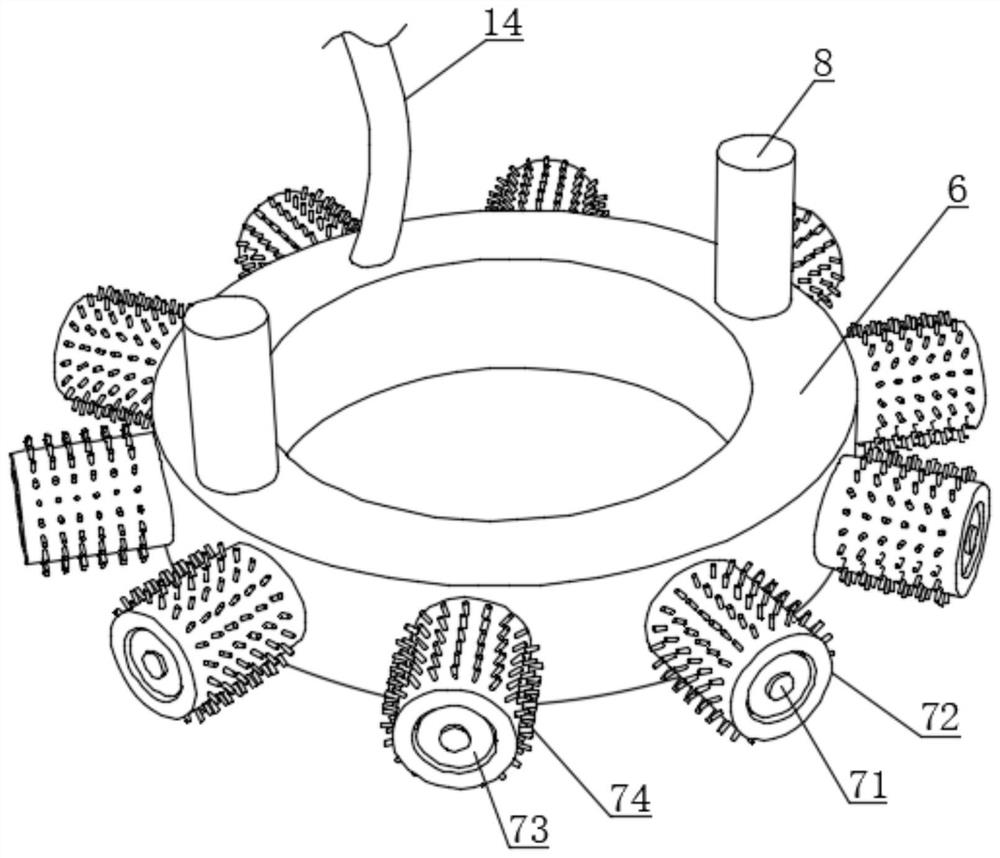

[0044] see Figure 1 to Figure 4 , a multi-effect synchronous continuous processing equipment for textile waste gas flocculent fibers, comprising a purification cylinder 1, the inner top of the purification cylinder 1 is fixedly connected with an annular straight cylinder 2, and the inner wall of the annular straight cylinder 2 is provided with a plurality of evenly distributed purification channels 201, the purification A pair of inner walls of the channel 201 are fixedly connected with a plurality of evenly distributed soft filter brushes 3, and the soft filter brushes 3 on a pair of inner walls of the purification channel 201 are evenly distributed at intervals, and the lengths of the plurality of soft filter brushes 3 are not uniform. It changes evenly. When the exhaust gas passes through the filter brush 3, the regularly distributed and uneven filter brush 3 facilitates the absorption of flocculent fibers in the exhaust gas. The inner ring plate 6 is arranged on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com