An integrated ceiling panel preparation system

An integrated ceiling and preparation system technology, applied in spraying devices, spray booths, etc., can solve problems such as low work efficiency, human hazards, and general spraying effects, so as to improve work efficiency, protect health, and shorten the drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

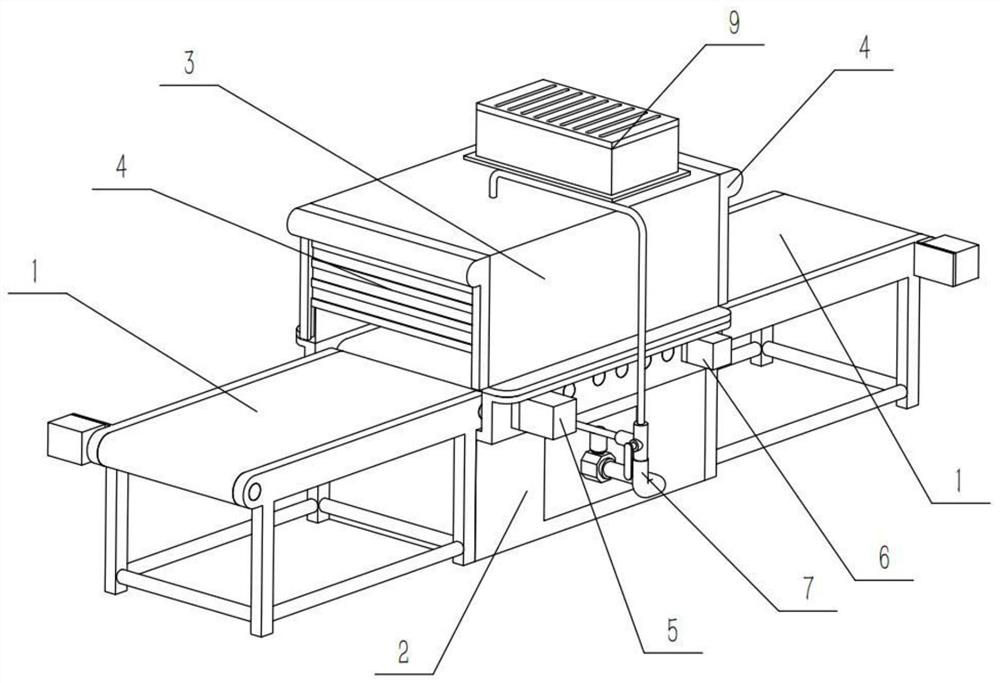

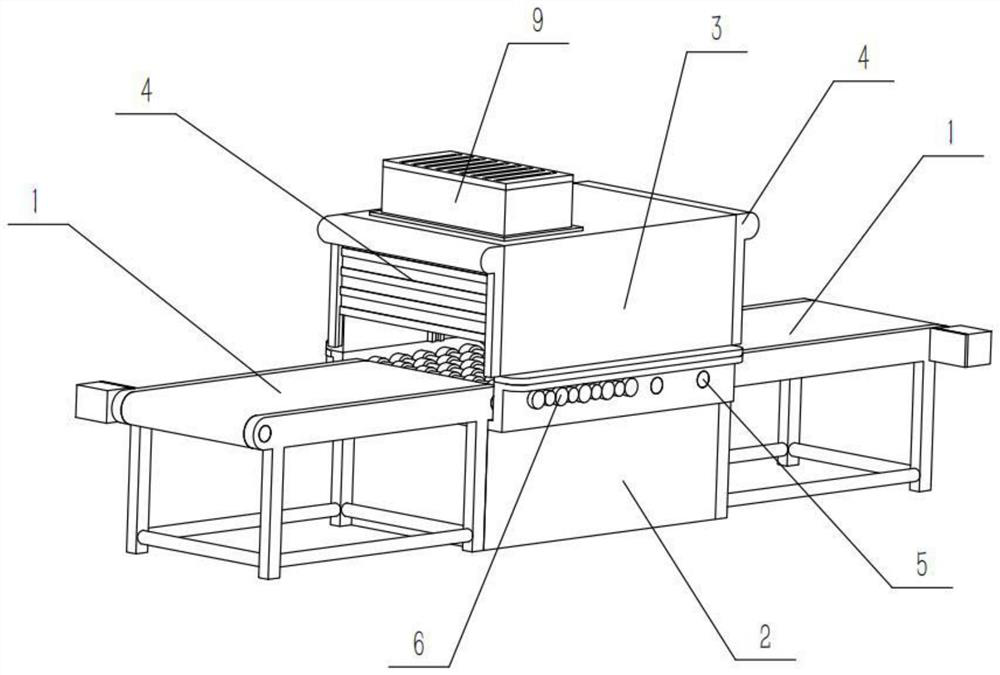

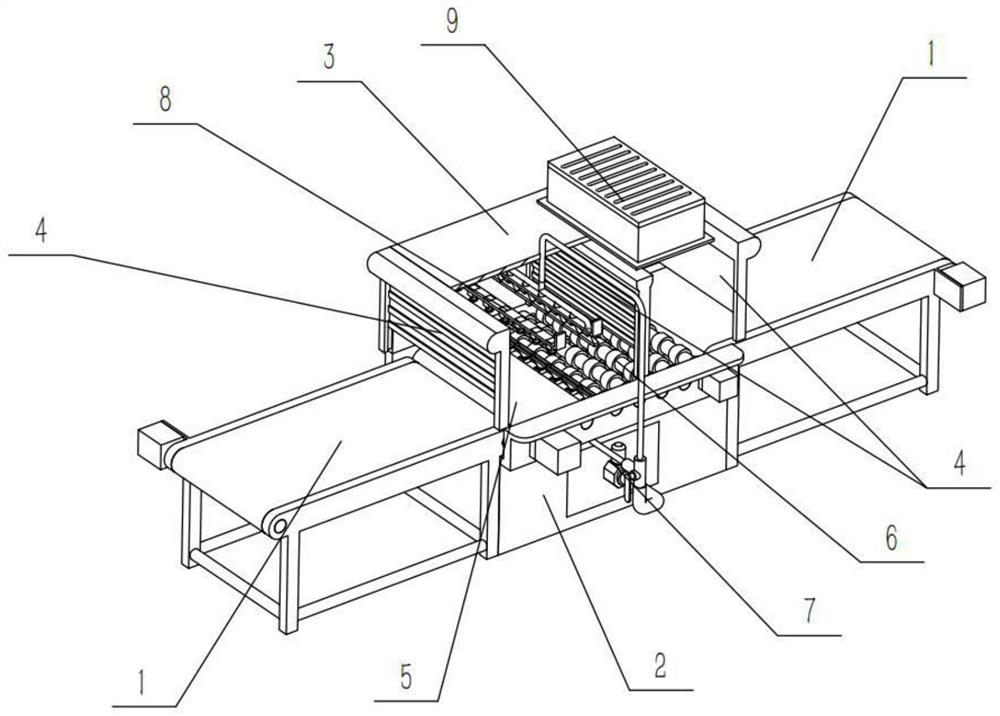

[0031] By below Figure 1-12 In the present embodiment, an integrated ceiling panel preparation system includes a transport mechanism I1, a roller shutter 4, and a transfer mechanism II5, and the integrated ceiling panel preparation system further includes a support frame 2, a top frame 3, a transport mechanism III6, a spray mechanism 7, The sensor mechanism 8, the exhaust mechanism 9, and the baking mechanism 10, the transfer mechanism I1 is provided with two, and the two transfer mechanism I1 are respectively disposed at both ends of the support frame 2, the transfer mechanism II5 and the transfer mechanism III6 respectively The front and rear sides of the upper end of the upper end frame 3 are disposed, and the upper top frame 3 is fixedly coupled to the upper end of the support frame 2, the baking mechanism 10 fixedly connected to the rear side of the upper end of the support frame 2, and the baking mechanism 10 is set At the lower side of the transfer mechanism III6, the spray...

specific Embodiment approach 2

[0033] By below Figure 1-12 In the present embodiment, the present embodiment will further explain the embodiment, and the transfer mechanism I1 includes a carriage 1-1, a conveyor belt I1-2, and a motor I1-3, the transfer belt I1-2 is disposed in a carriage 1. The upper end of -1, the motor I1-3 fixed to the carrier 1-1, and the output shaft of the motor I1-3 is fixed to a certain belt of the conveyor belt I1-2, and the two carriage 1-1 It is disposed at both ends of the support frame 2.

[0034] Place the integrated ceiling panel to be sprayed to the front side of the conveyor belt I1-2, when placing the integrated ceiling panel, there is no need to worry about the front and reverse surface, and do not need to worry about the position on the conveyor belt I1-2, and ensure the flat state, Shorten the preparation time, improve the working efficiency, and the conveyor belt I1-2 drives a plurality of integrated ceiling panels to the conveyor tape II5-2.

specific Embodiment approach 3

[0035] By below Figure 1-12 In this embodiment, the present embodiment will further explain the embodiment, and the transfer mechanism II5 includes a motor II5-1 and a conveyor belt II5-2, and the two pulleys of the transfer belt II5-2 rotate connected to the support frame 2. The upper end, the motor II5-1 is fixed to the support frame 2, and the output shaft of the motor II5-1 is fixed to the pulley of the belt II5-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com