Welding jig for liquid crystal module FPC

A liquid crystal module and welding jig technology, applied in welding equipment, manufacturing tools, components of lighting devices, etc., can solve the problems of not being able to weld the FPC to be welded, affecting the welding operation, etc., and achieve the effect of reducing the amount of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

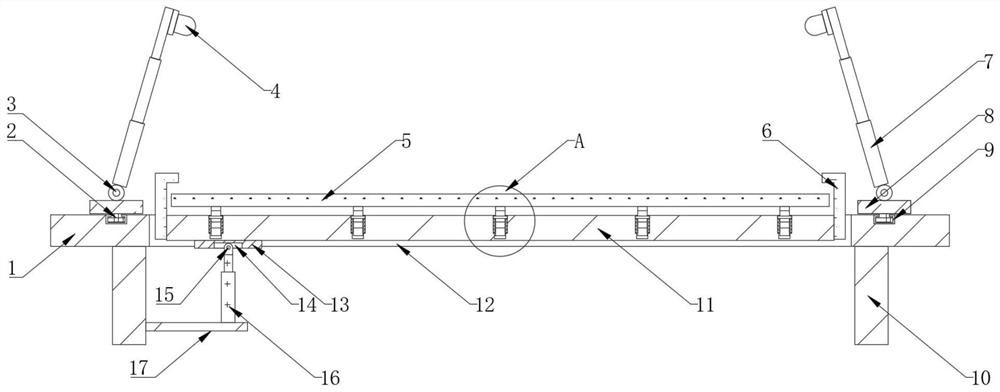

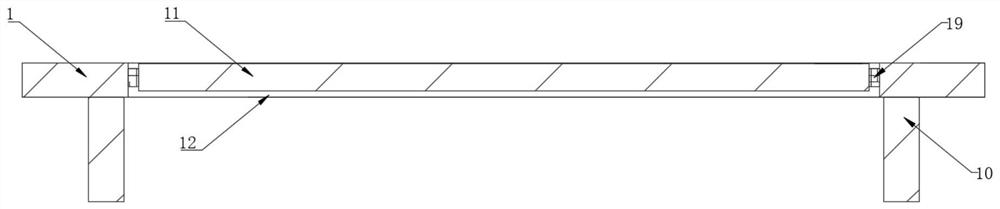

[0024] see Figure 1~2 , in the embodiment of the present invention, the welding fixture of the liquid crystal module FPC includes a workbench 1, the four corners of the bottom end of the workbench 1 are connected with supporting feet 10, and the top of the workbench 1 is provided with a mounting hole 12, and the workbench 1 The bottom is provided with a mounting frame 17, and the top of the workbench 1 is provided with an FPC placing plate 11, and both sides of the FPC placing plate 11 are connected with fixing fixtures 6, and the top of the mounting frame 17 is equipped with an electric telescopic rod 16, and the electric telescopic rod 16 The top is provided with a second slider 15, and one side of the bottom end of the FPC placement plate 11 is connected with a connecting plate 13, and the bottom end of the connecting plate 13 is provided with a second chute 14, and the front and rear parts of the mounting hole 12 are provided with a rotating shaft 19.

[0025] Wherein, bo...

Embodiment 2

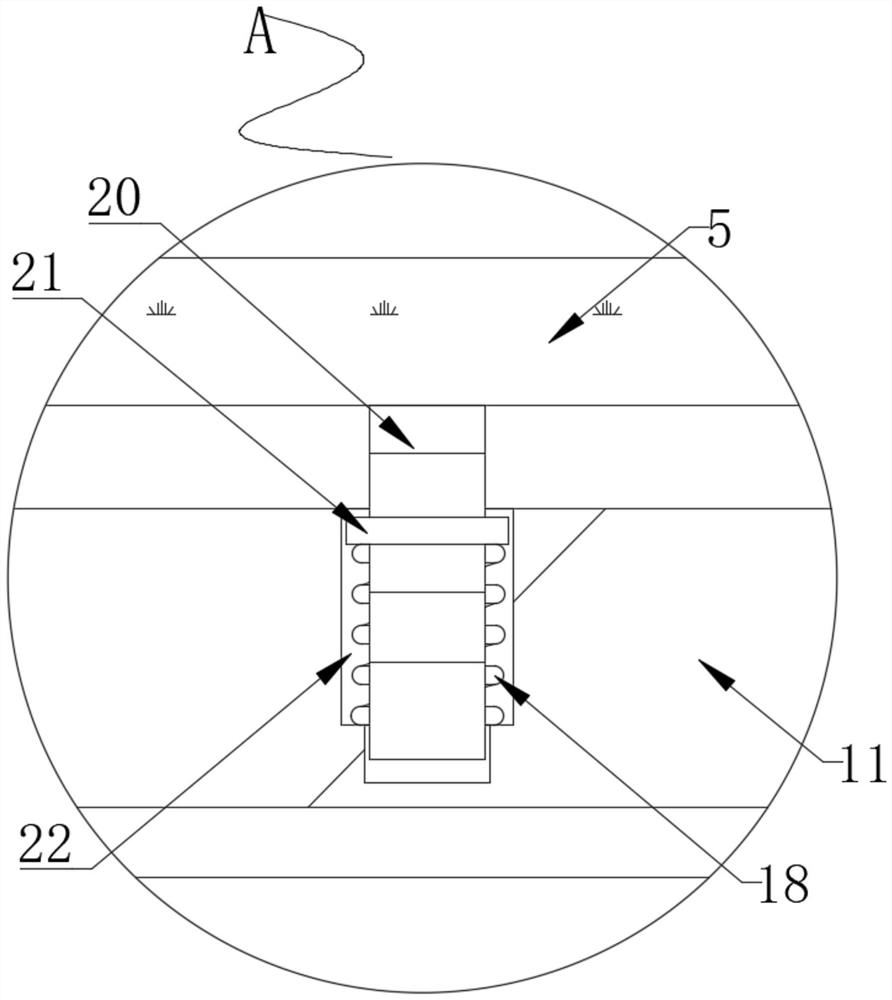

[0031] refer to figure 1 , 3 And 4, the welding jig of liquid crystal module FPC, this embodiment is compared with embodiment 1, also includes that the top of FPC placement board 11 is provided with balance board 5, and the top of FPC placement board 11 is equidistantly provided with several grooves 22. A limit spring 18 is installed inside the groove 22, and a plurality of adjusting rods 20 are equidistantly connected to the bottom end of the balance board 5, and the outside of the adjusting rod 20 is sleeved with a limit ring 21.

[0032] Wherein, one end of the limiting spring 18 is connected to the inner side of the groove 22 , and the other end of the limiting spring 18 is connected to the bottom end of the limiting ring 21 .

[0033] Working principle: Since the surface of the liquid crystal module is not completely flat, when the liquid crystal module is placed on the FPC placement board 11, the unevenness of the liquid crystal module will make the liquid crystal modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com