A kind of prestressed prefabricated concrete pipe pile pouring molding process

A technology of prefabricated concrete and forming process, applied in strengthening forming, manufacturing tools, ceramic forming machines, etc., can solve problems such as abnormal wear of screw holes, improper locking, and damage to casting molds, so as to avoid abnormal wear and improper locking , to avoid the effect of modeling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

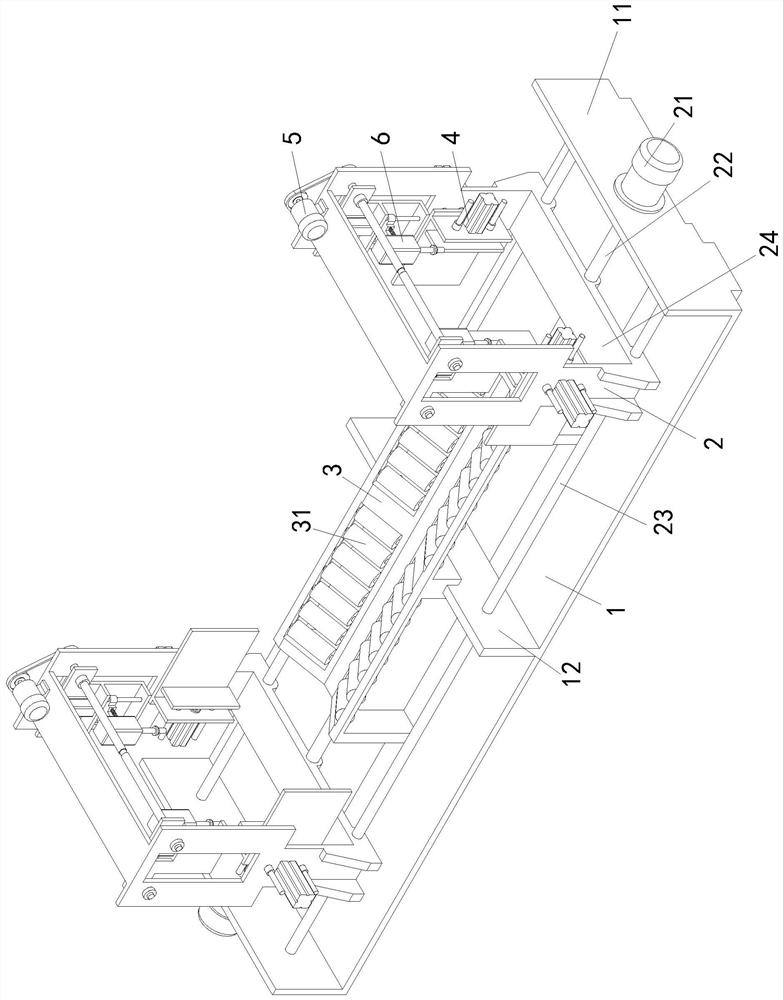

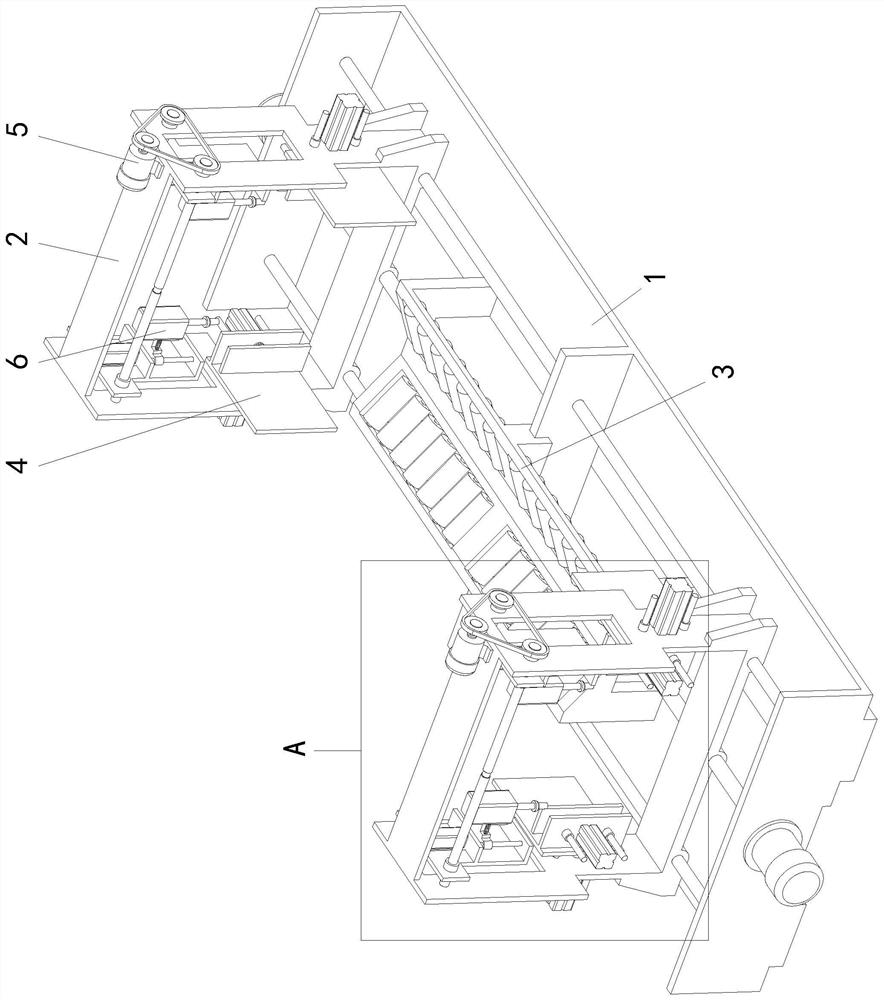

[0033] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, with the purpose of helping those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

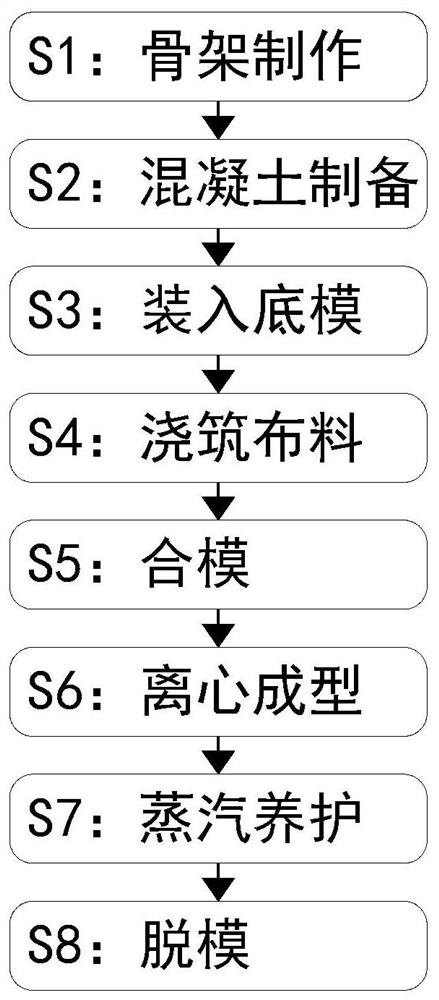

[0034] See attached Figure 1-8 As shown, a prestressed prefabricated concrete pipe pile pouring forming process, the forming process specifically includes the following steps:

[0035] S1. Skeleton production: according to the design diameter and length of the pipe pile, the pouring skeleton is made and formed;

[0036] S2. Concrete preparation: mixing and preparing concrete according to the ratio of raw materials, and use it as pipe piles for pouring;

[0037] S3, loading the bottom mold: placing the processed tubular pile skeleton in the bottom mold;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com