Movable stirrer

A mixer and mixing box technology, used in cement mixing devices, control devices, cleaning hollow objects, etc., can solve the problems of reducing the life of the mixer, the complexity of the mixer operation, concrete hardening, manual opening, etc., to reduce the operation burden and increase transmission. Power, the effect of reducing the burden on the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

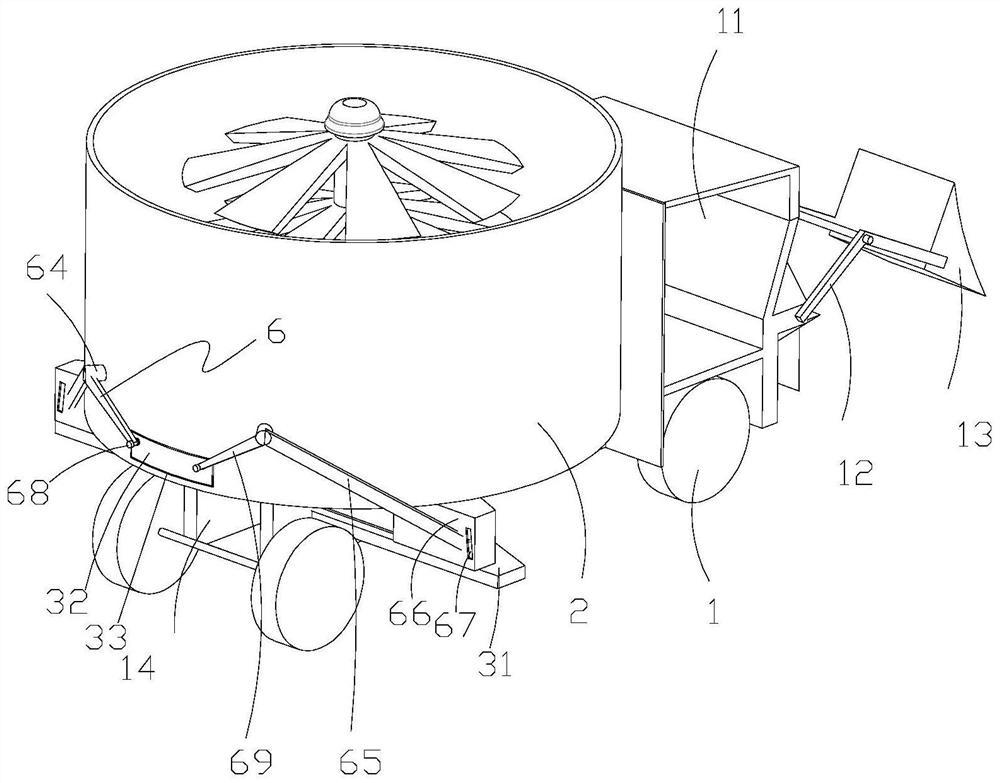

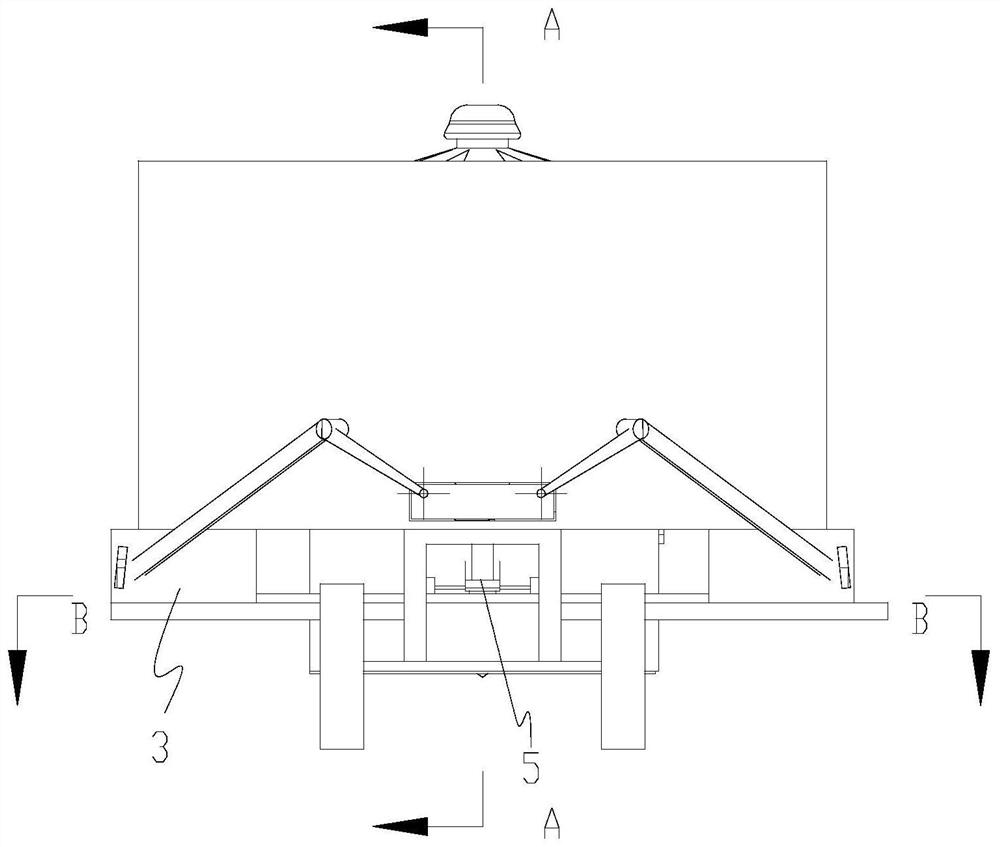

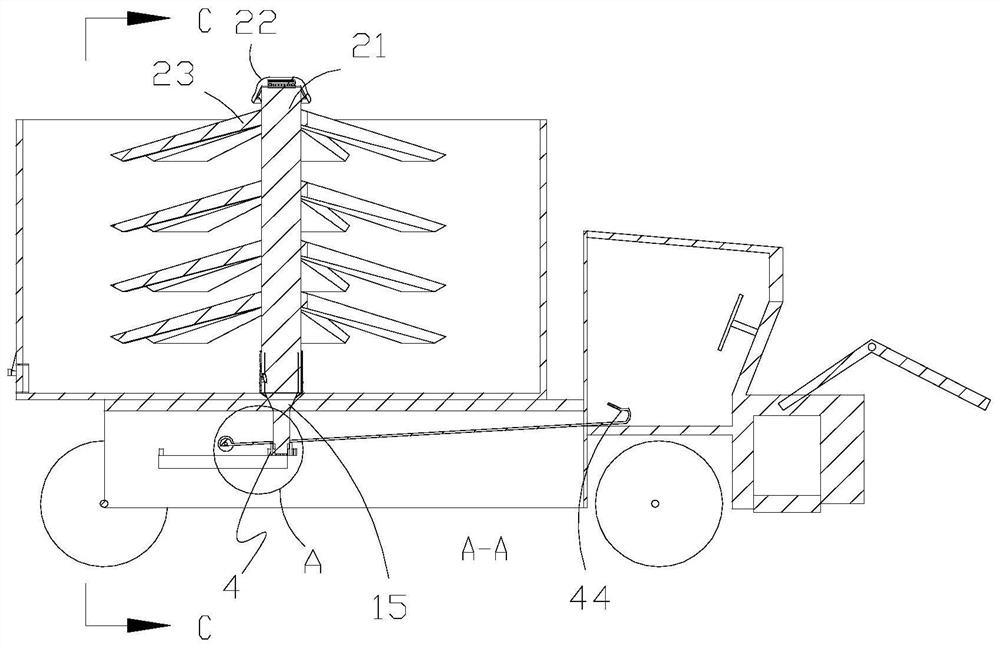

[0026] Such as Figure 1-12Shown, a kind of movable mixer comprises vehicle frame 1, first support plate 14, mixing box 2, transmission device 3, cockpit 11, hydraulic rod 12, bucket 13, motor 15; First support plate 14 is set On the frame 1, it is a C-shaped notch downward, and both ends are fixedly connected to the frame 1; the mixing box 2 is set on the first support plate 14, and the whole is circular and thin-walled; the transmission device 3 is set on the frame On the frame 1, located at the bottom of the vehicle, driven by the force of the rotating shaft; the cockpit 11 is set on the frame 1, with a protective glass on the top, and the hydraulic rod 12 is set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com