Double-rope dual-connection mechanism for automatic telescopic sealing-tape machine structure

An automatic telescopic and tape machine technology, applied in the field of stackers, can solve the problems of reducing the service life of gears and racks, low storage rate in the stockyard, and a large amount of time, so as to reduce operating costs and increase storage utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

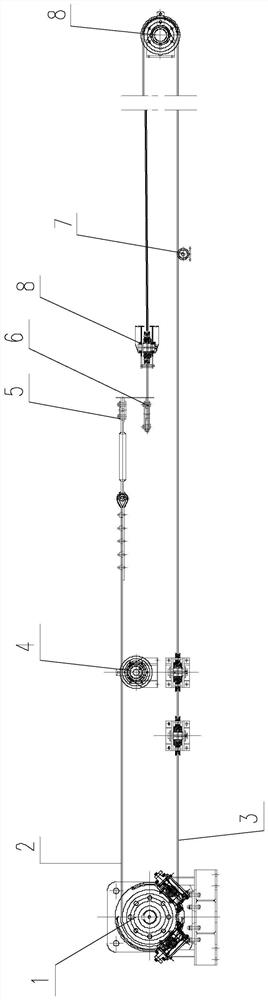

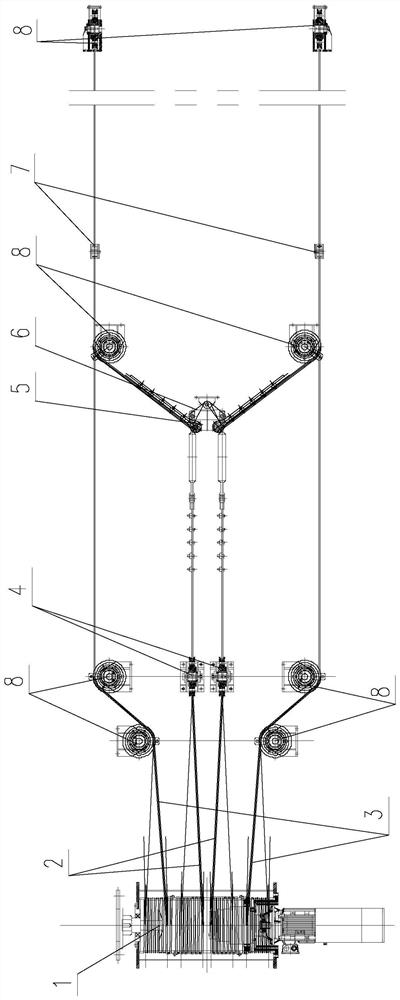

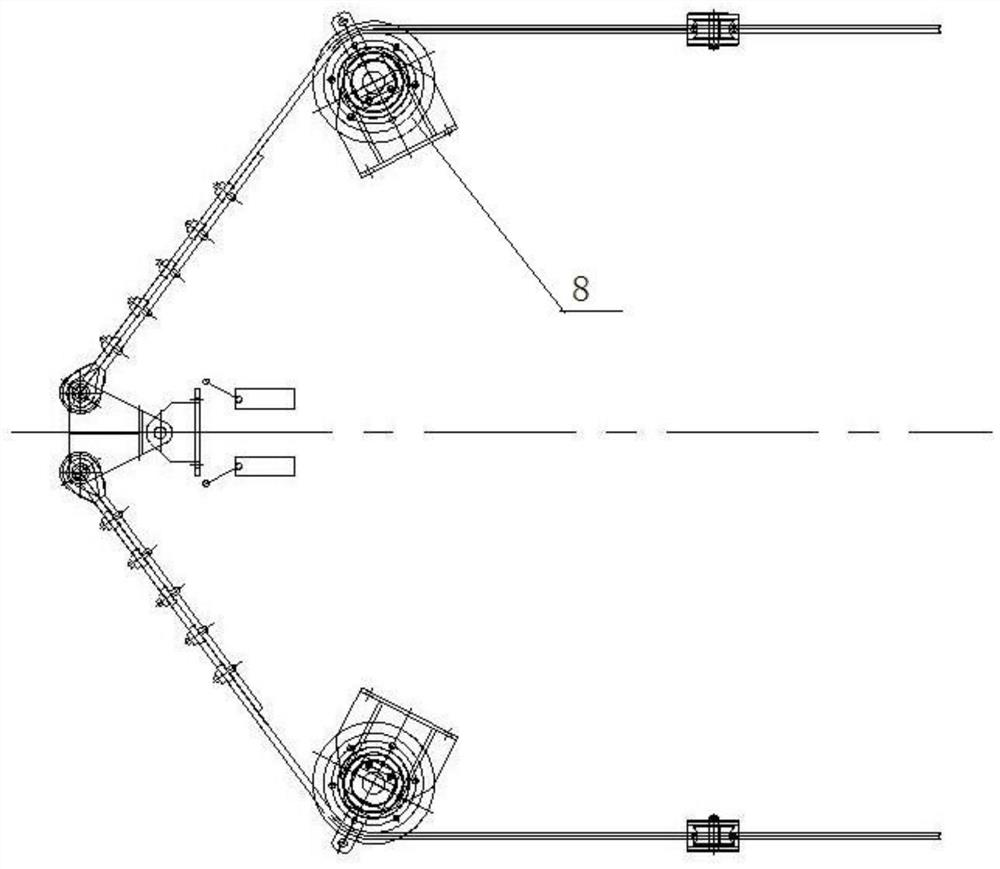

[0020] Referring to the accompanying drawings, a double-rope double-connection mechanism used in the structure of an automatic retractable tape machine includes an electric winch 1, two upper-outlet wire ropes 2, two lower-outlet wire ropes 3, a supporting pulley block 4, and an upper-outlet wire rope balance Mechanism 5, lower wire rope balance mechanism 6, support wheel group 7, reversing pulley block 8, two upper wire ropes 2 are connected to the electric hoist 1, two lower wire ropes 3 are connected to the electric hoist 1, two upper wire ropes The wire rope 2 is connected with the support pulley block 4, the upper wire rope balance mechanism 5 is connected with the support pulley block 4, and the two lower wire ropes 3 are connected with the redirection pulley block 8, and the redirection pulley block 8 is balanced with the lower outlet wire rope through the support pulley group 7 Bodies 6 are connected.

[0021] The cantilever tape machine on the stacker equipment used i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap