Preparation and application of a copper porphyrin catalyst and its composite material

A technology of composite materials and catalysts, applied in physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve the problems of high cost of noble metals, high conversion voltage, consumption of electrolytes, etc., to achieve Fewer synthesis steps, mild conditions, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 Synthesis of bridged dialdehydes

[0089] The present embodiment discloses the concrete method of bridging dialdehyde: specifically comprises the following steps:

[0090] Step 1. Fully grind the anhydrous potassium carbonate into powder, and bake at 200°C for 3 to 5 hours;

[0091] Step 2, under vigorous stirring, add powdered anhydrous potassium carbonate (20g, 145mmol) to N,N-dimethylformamide (80ml), and keep the temperature at 60°C under the protection of inert gas;

[0092] Step 3, add 5-tert-butyl salicylaldehyde (7.3g, 60.0mmol), maintain about 10 minutes;

[0093] Step 4. Add 1,3-dibromopropane (6.1g, 30mmol) to the reaction mixture, continue stirring for 12h, and track with a thin-layer chromatographic plate until the ratio of the product to the raw material does not change;

[0094] Step 5. Cool the reaction solution to -5°C, slowly add 100ml of water, and maintain the temperature of the reaction solution at 0 to 5°C when adding water;

[0095] S...

Embodiment 2

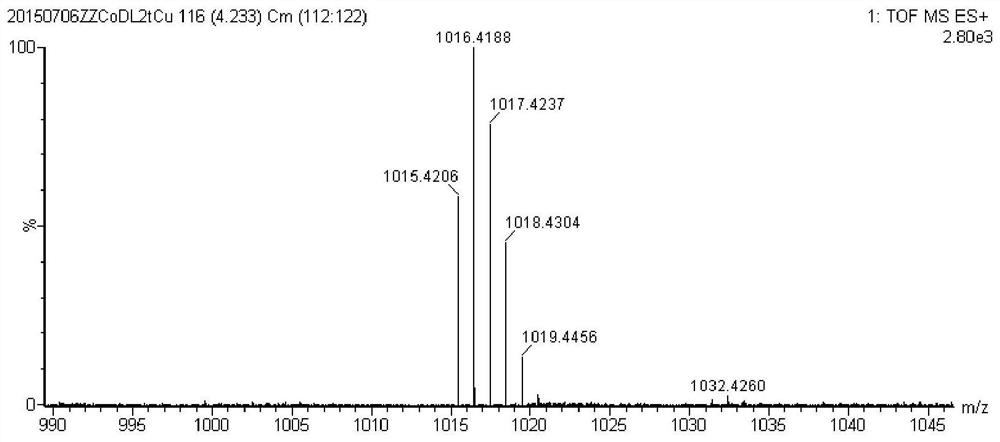

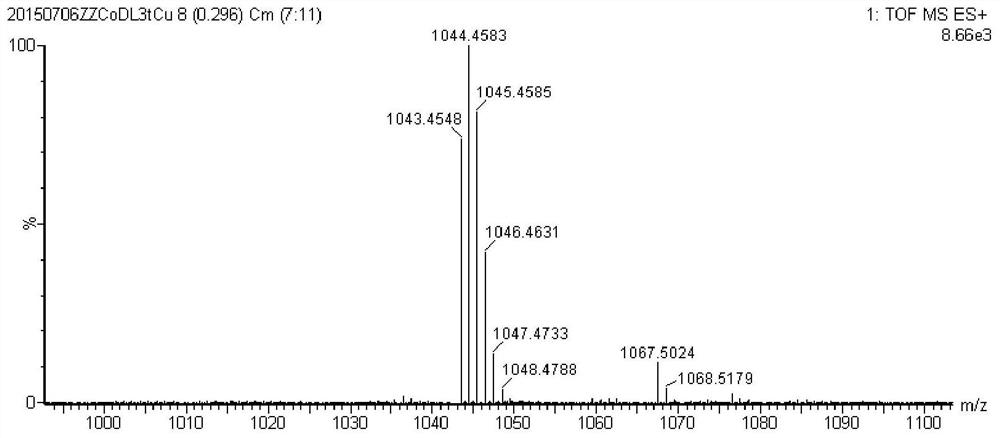

[0096] Example 2 Preparation of wavy and saddle copper porphyrins

[0097] The present embodiment discloses the preparation method of 2-Cu-w and 2-Cu-s, which specifically includes the following steps:

[0098] Step 1. Take carbon three dialdehyde (3.8g, 10mmol), pyrrole (1.4mL, 20mmol) and Cu(OAc) 2 ·2H 2 O (3.6 g, 20 mmol) was added portionwise to 200 mL of boiling propionic / butyric acid mixture (2:1, v / v); after 20 min at reflux, the air was shut off and stirring continued for 45 min.

[0099] Step 2, steaming and removing the mixed acid while hot and under reduced pressure;

[0100] Step 3, soak the solid residue with dichloromethane three times (80 mL×3), combine the soaking liquid, wash the solution with water five times, and dry with anhydrous sodium sulfate;

[0101] Step 4. After the solvent is evaporated, the first color band is separated by silica gel column chromatography with dichloromethane / petroleum ether (1:4, v / v), and the first color band is separated with...

Embodiment 3

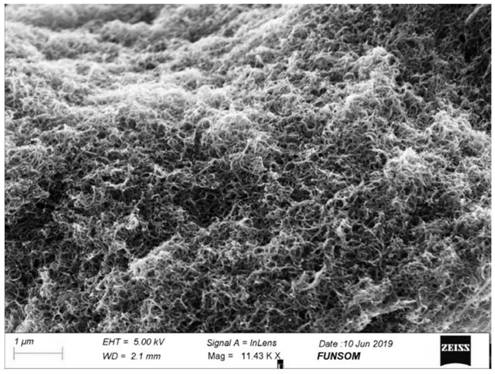

[0102] Example 3 Preparation of wrinkled copper porphyrin

[0103] The present embodiment discloses a preparation method of 1-Cu-r, which specifically includes the following steps:

[0104] Step 1, take carbon three bisaldehyde white (3.8g, 10mmol), nitrophenyl bispyrrole methane (5.3g, 20mmol) and Cu(OAc) 2 ·2H 2 O (3.6 g, 20 mmol) was added portionwise to 200 mL of boiling propionic acid. After refluxing for 10 to 15 minutes, another equivalent of pyrrole (0.67 g, 10 mmol) was added to the mixed solution, and the air was isolated after refluxing for 20 minutes, and stirring was continued for 45 minutes;

[0105] Step 2, then steam under pressure while still hot to remove propionic acid;

[0106] Step 3. The solid residue was soaked three times with dichloromethane (80 mL×3), the soaking solutions were combined, the solution was washed with water five times, and dried with sodium sulfate.

[0107] Step 4. After removing the solvent, separate with dichloromethane / petroleum e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com