Crotch three-dimensional shaping processing method

A processing method and crotch technology are applied in the field of crotch three-dimensional shaping processing, which can solve the problems of uneven clothing, affecting the beauty and comfort of clothing, and achieve the effects of more obedient appearance, efficient shaping efficiency, and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

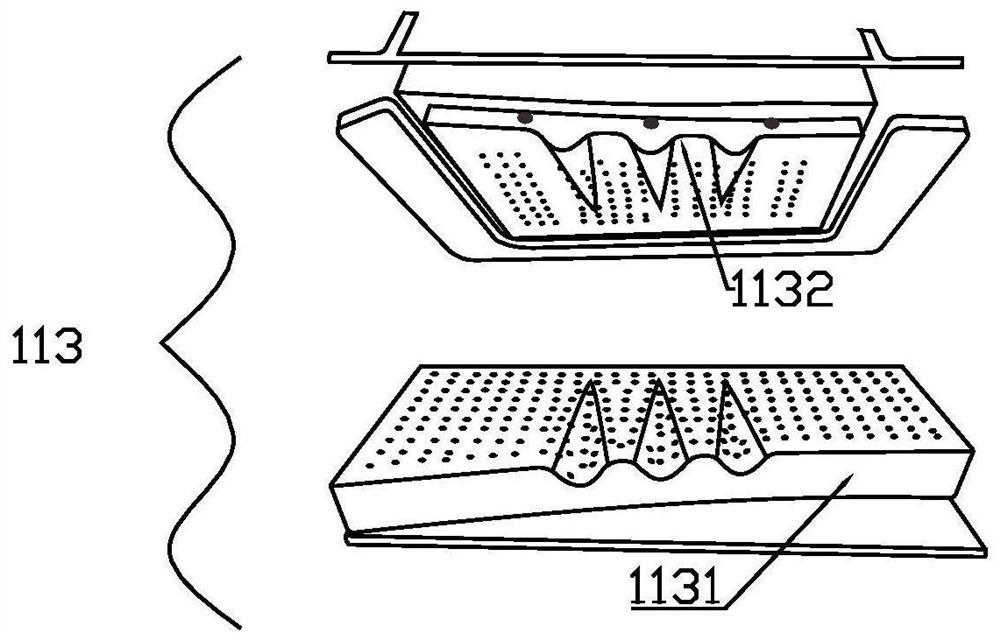

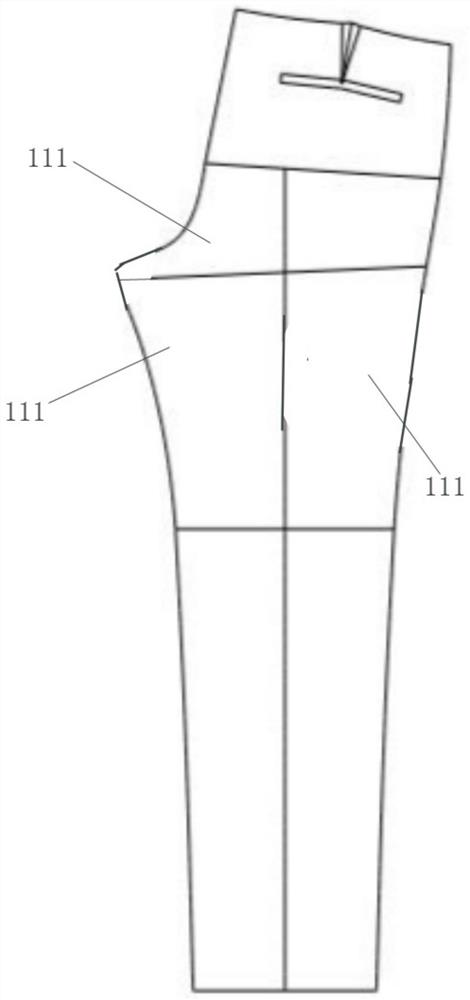

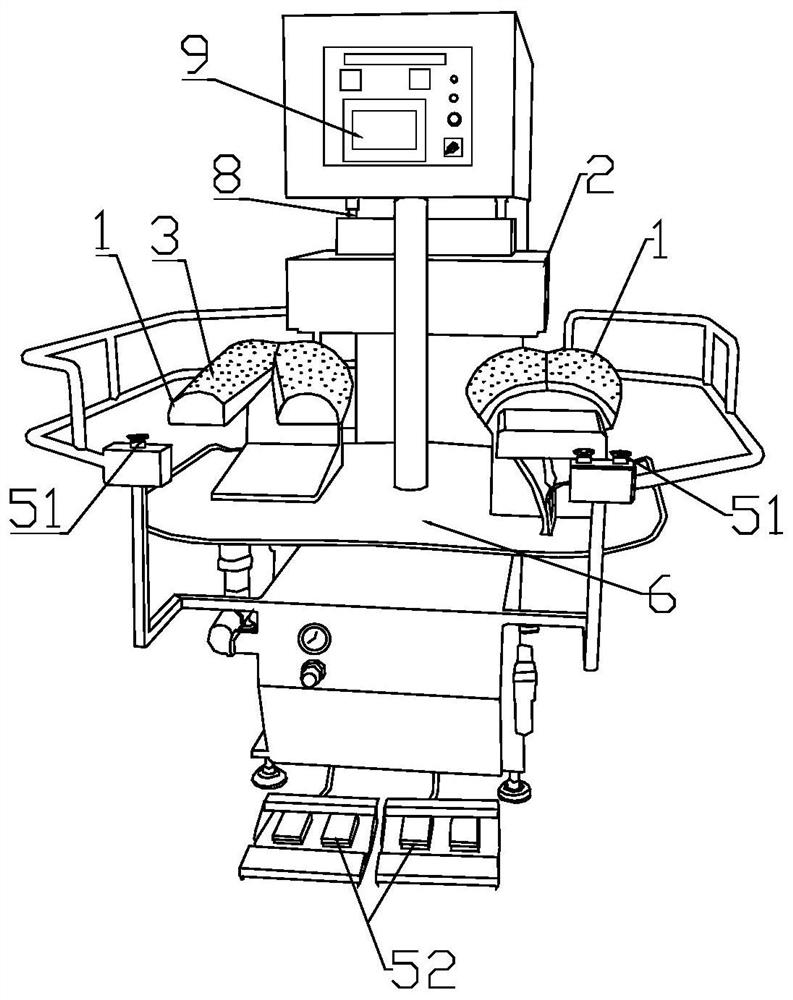

[0040] The present invention is described below in conjunction with accompanying drawing:

[0041] as attached Figure 1~6 Shown:

[0042] A crotch three-dimensional shaping processing method is characterized in that it may further comprise the steps:

[0043] S1. Prepare the fabric, loosen the fabric before cutting, and allow the fabric to retract for 24 hours;

[0044] S2, cut according to the required size, and cut into trousers to form a sheet: two pieces for the front and two pieces for the back piece;

[0045] S3. Set the buttocks of the two rear panels as the back wave position, and perform high-temperature shaping and pulling on the inner and outer sides of the back wave to form a predetermined shape;

[0046] S4. Carry out sewing, install front and rear pockets, install zippers, upper waistband, partially add jujubes to fix and open water hyacinths to form finished trousers;

[0047] S5, washing and ironing the finished product;

[0048] S6. Finally, carry out hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com