A kind of polypropylene composite material and its preparation method and shaping process

A composite material and polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve problems such as aging degradation, limited use of PP, poor cold resistance, etc., and achieve the effect of enhancing toughness and impact resistance and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

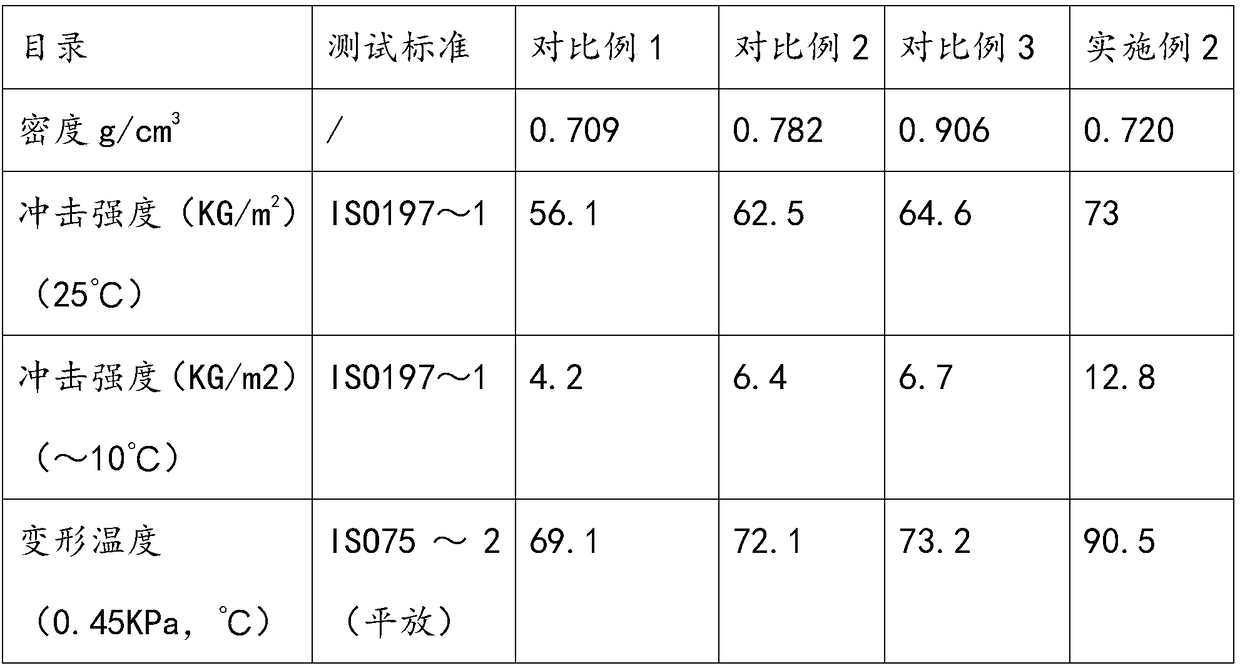

Examples

Embodiment 1

[0024] The composite material disclosed in the present invention comprises: polypropylene with a weight ratio of 60% to 75%, a filler with a weight ratio of 17% to 28%, a foaming agent with a weight ratio of 2% to 5%, and a weight ratio of 1%. ~2% elastic agent and weight ratio are 0.1%~0.2% antioxidant; Wherein, filler is talcum powder or aluminum oxide powder; Described foaming agent is a kind of in magnesium carbonate, calcium carbonate, sodium bicarbonate ; The elastic agent is EPDM rubber, grafted EPDM rubber or polyene; the antioxidant is a mixture of phosphite secondary antioxidant and metal ion deactivator.

Embodiment 2

[0026] In this embodiment, the filler is talcum powder, the foaming agent is magnesium carbonate, the elastic agent is EPDM rubber, and the antioxidant is a mixture of phosphite antioxidant and metal ion deactivator.

[0027] The concrete preparation method of polypropylene composite material comprises the following steps:

[0028] (1) Propylene is used as raw material to produce polypropylene in a gas phase reactor, and inert gas protection is required to control the aggregation state of the polymer to obtain a specific product structure, that is, polypropylene at a temperature of 230°C and a pressure of 2.16Kg. The melt flow rate is 1.0-20.0g / 10min, and the recommended melt flow rate is 3.0-7.0g / 10min.

[0029] (2) On the basis of the polypropylene prepared by the gas phase reactor, the prepared polypropylene and other raw materials are 70% polypropylene by weight, 20% talc by weight, and 4% magnesium carbonate by weight. , 1.9% by weight of EPDM rubber and 0.15% by weight ...

Embodiment 3

[0045] The shaping process of the polypropylene composite material prepared by embodiment 2 is as follows:

[0046] Since the melting point of polypropylene is between 164°C and 174°C, and the melting point range is narrow, the present invention proposes a shaping process that shrinks at high temperature, uses at low temperature, and eliminates internal stress.

[0047] The shaping process is as follows: Aiming at the shrinkage gradient of the polypropylene material during the heating process, keep the shrinkage temperature at 170°C to 180°C for 2 to 6 minutes, then keep the shrinkage temperature at 100°C to 130°C for 25 to 30 minutes, and finally Water cooling is used for shaping.

[0048] The rollers can be used to input and output synchronously at the mouth of the drying tunnel, and the drying tunnel can be heated by infrared rays or microwaves.

[0049] For films made of small rolls or narrow polypropylene composite materials, since the width of the film is very small, ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com