Forming and winding equipment for capacitor shell processing

A technology for capacitors and shells, which is applied in the field of forming and winding equipment for capacitor shell processing. It can solve the problems of poor effect and low winding efficiency of aluminum sheets, and achieve the effects of convenient use, effective and stable heating, winding and shaping, and improved continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

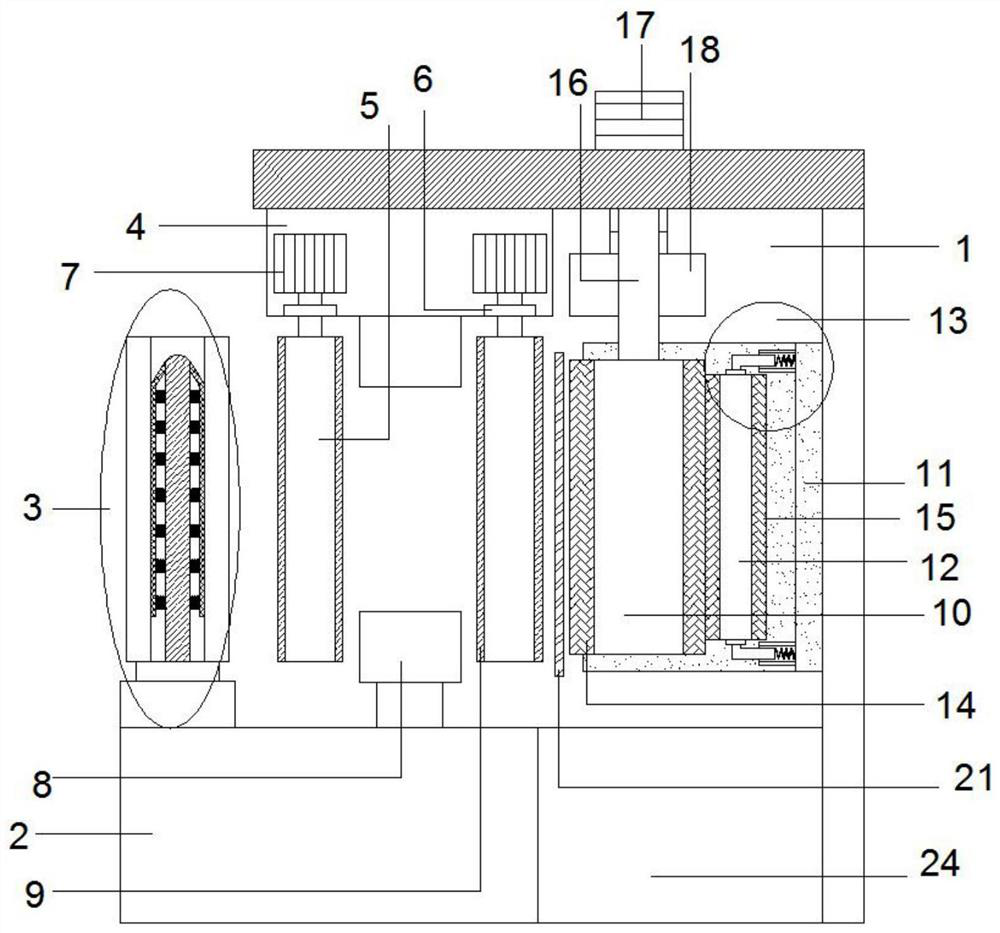

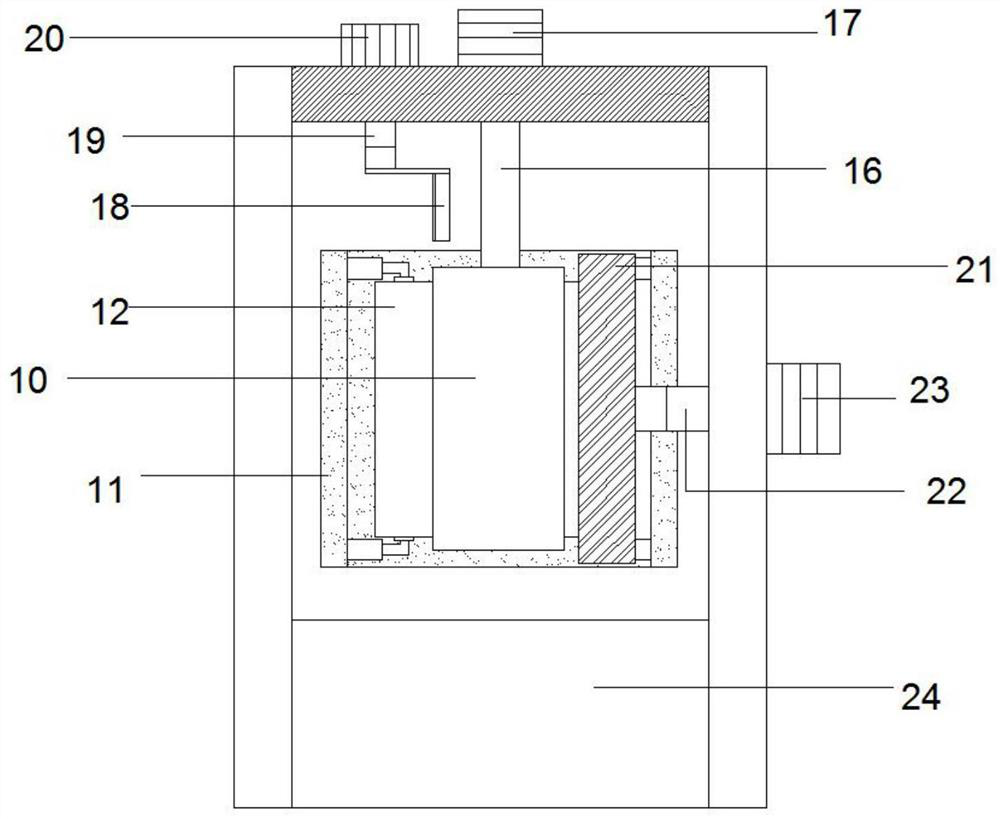

[0031] refer to Figure 1-6 , a forming and winding equipment for capacitor casing processing, comprising a winding box 1, a base 2 below the winding box 1, a placement mechanism 3 on the left side of the winding box 1 and a winding roller 10 on the right side of the winding box 1, The placement mechanism 3 is arranged above the left side of the base, and a winding shaft 31 is placed on the placement mechanism 3, a first heating layer 14 is arranged outside the winding roller 10, and a U-shaped heating layer 14 is arranged on the right side of the winding roller 10. Protective plate 11, the outer side of U-shaped protective plate 11 is connected with the side wall of winding box 1, and the inside of U-shaped protective plate 11 is connected with the surface of winding roller 10 through a plurality of sizing rollers 12, and the upper and lower ends of sizing roller 12 are connected with U The connecting mechanism 13 arranged inside the protective plate 11 is connected in rotati...

Embodiment 2

[0037] like Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the placement mechanism 3 includes a rotating block 32 that is rotatably connected above the base 2, and a fixed column 28 that is fixedly connected above the rotating block 32. The winding shaft 31 It is sleeved on the outside of the fixing column 28 . It can effectively and conveniently fix the aluminum coil and improve the stability of the aluminum coil.

[0038]In order to further fix the winding shaft 31 and improve the stability, preferably, a bent plate 29 is arranged symmetrically on both sides of the outside of the fixed column 28, the upper end of the bent plate 29 is connected to the top of the fixed column 28, and the lower end is connected to the top of the fixed column 28. It extends toward the lower end of the fixed column 28 , and the bent plate 29 is connected to the fixed column 28 through a plurality of connecting springs 30 .

Embodiment 3

[0040] like Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two sets of guide rollers 5 are arranged inside the winding box 1 , and the two sets of guide rollers 5 are symmetrically arranged on the left and right sides of the U-shaped guide plate 8 . Effectively improve the stability of aluminum strip transmission.

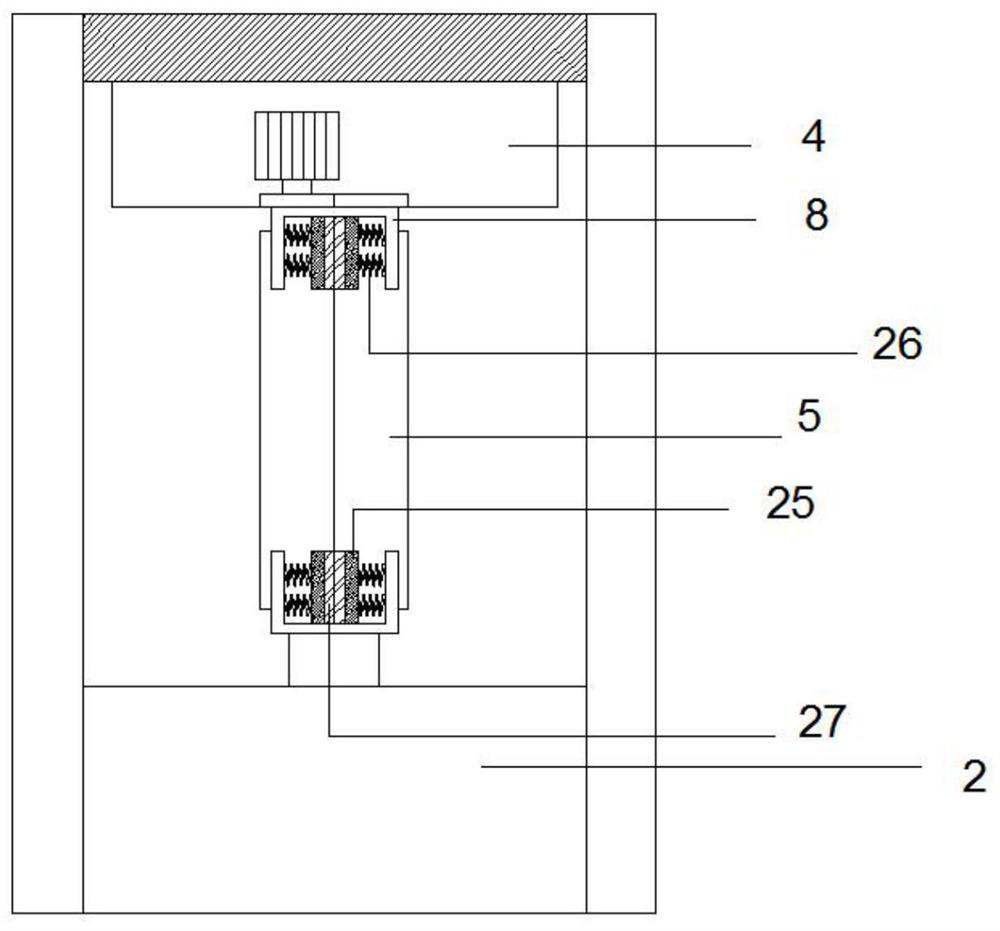

[0041] In order to further improve the stability of the aluminum strip during the transmission process and at the same time enhance the safety of the device, preferably, a protective box 4 is provided on the left side of the lower end of the top of the winding box 1, and the upper end of the guide roller 5 passes through the protective box 4 It is connected with the rotating gear 6, and the rotating gear 6 between the two guide rollers 5 of each group meshes with each other, and one of the guide rollers 5 passes through the rotating gear 6 and is connected to the first motor 7 inside the winding box 1 , and the U-shaped gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com