Sucker Rod Makeup and Breakout Back Tong Rotary Alignment Clamping Device and Using Method for Workover Operation

A clamping device and sucker rod technology, applied in drill pipe, earthwork drilling, drilling equipment, etc., can solve problems such as difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

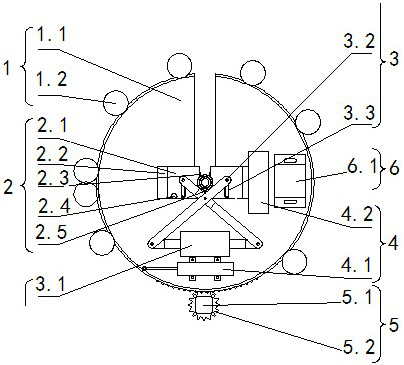

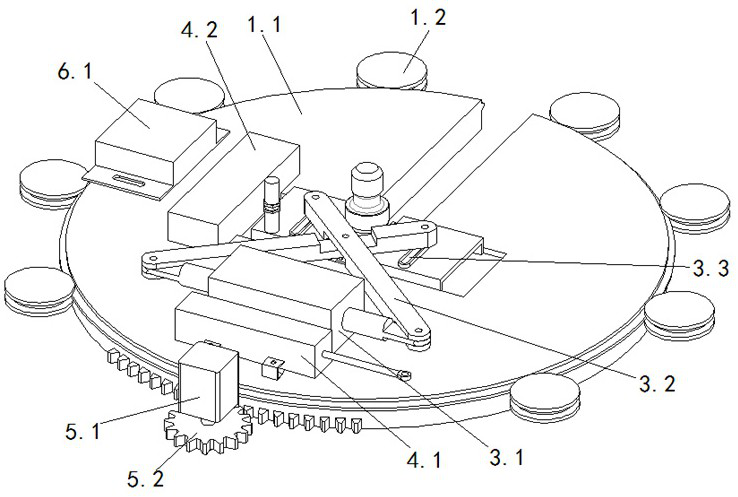

[0026] Embodiment 1, with reference to figure 1 and 2 , a kind of workover work sucker rod make-up and breakout back tong rotary aligning and clamping device mentioned in the present invention is installed on the workover sucker rod power tong back tong and is used in conjunction with workover power tong. The commonly used 3YC Take the type workover sucker rod power tong as an example. The maximum torque of this power tong is 3000N·m, which is suitable for making up and breaking down small-diameter tubing. .

[0027] The rotary aligning and clamping device for sucker rod make-up and breakout back-up tongs for well workover operations includes a rotating base plate assembly 1, a guide clamping assembly 2, a lever type force adding assembly 3, a pull rod type displacement sensor assembly 4, a rotating power assembly 5 and The control assembly 6, the rotating base plate assembly 1 includes an open base plate 1.1, a plurality of rollers 1.2; the rollers 1.2 are installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com