Control and adjustment system and method under combined heat supply mode of plant-level thermal power units

A technology of combined heating and control and regulation, applied in the heating system, heating method, space heating and ventilation details, etc., can solve the problem of untimely heating control, reduce the loss of the heating network, and improve the flexible regulation ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In order to better allocate heat load resources, improve utilization, and take into account the peak shaving demand faced by new energy consumption, multi-unit joint automatic adjustment is required to enhance the role of the main control system of the first station of heating, and give full play to the participation of each unit in different periods of time. Ability to regulate thermal and electrical loads. Embodiments of the present invention provide a control and adjustment system and method in a plant-level multi-unit joint heating mode.

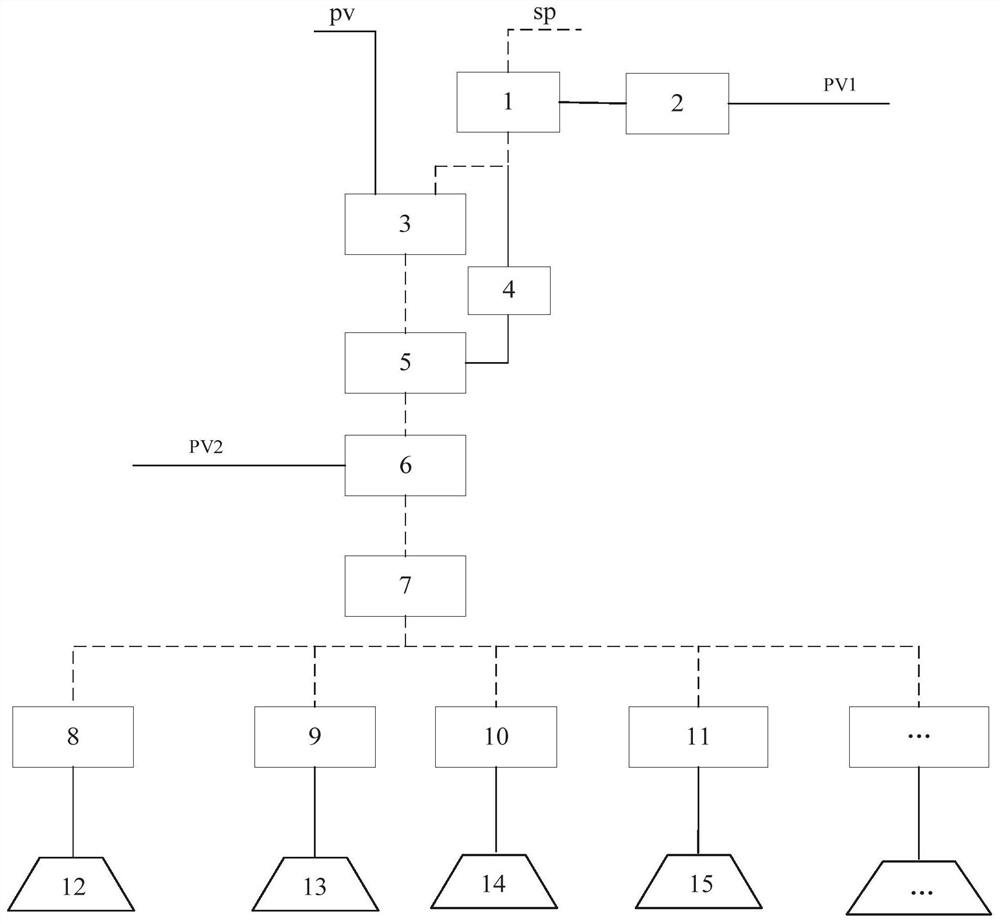

[0044] figure 1 It is a functional principle block diagram of the control and regulation system in the plant-level multi-unit joint heating mode described in Embodiment 1 of the present invention.

[0045] Such as figure 1As shown, the control and adjustment system provided by Embodiment 1 of the present invention under the joint heating mode of multiple units at the factory level includes multiple heating units, and also includ...

Embodiment 2

[0066] Such as figure 1 As shown, Embodiment 2 of the present invention provides a plant-level control and adjustment system in the joint heating mode of multiple units.

[0067] figure 1 Middle: PV is the process variable, representing the water supply temperature; PV1 is the return water temperature; PV2 is the average value of the adjustment instructions of the participating heating units; sp is the set value of the water supply temperature.

[0068] The first computing module 1 is an adder. The calibration calculation unit 2 is a function calibrated according to the return water temperature, and the output of the function and sp are added through the first calculation module 1 .

[0069] The second calculation module 3 is a controller, which mainly performs comparison calculations based on the output of the first calculation module 1 and the PV value.

[0070] The feedforward operation module 4 is a feedforward function, and the third operation module 5 is an adder. The...

Embodiment 3

[0082] Embodiment 3 of the present invention provides a computer storage device, including a memory and a processor, the processor and the memory communicate with each other, the memory stores program instructions executable by the processor, and the processor calls The program instruction can execute the method for regulating and controlling the combined heat supply unit. The method comprises the steps of:

[0083] After the return water temperature is calibrated, it is added to the set value of the supply water temperature to obtain the first calculated value;

[0084] Comparing the first calculated value with the water supply temperature, performing proportional integral calculation according to the obtained numerical deviation state, to obtain the second calculated value;

[0085] Perform numerical conversion of the first operation value through a feedforward function to obtain a feedforward value;

[0086] accumulating the second calculated value and the feedforward val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com