A reaction device for chemical vapor deposition

A technology of chemical vapor deposition and reaction equipment, which is applied in the field of heat treatment processing, can solve the problems of uncontrollable gas and shallow depth of infiltrated layer, and achieve the effects of improving flexible adjustment, stable quality of infiltrated layer, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

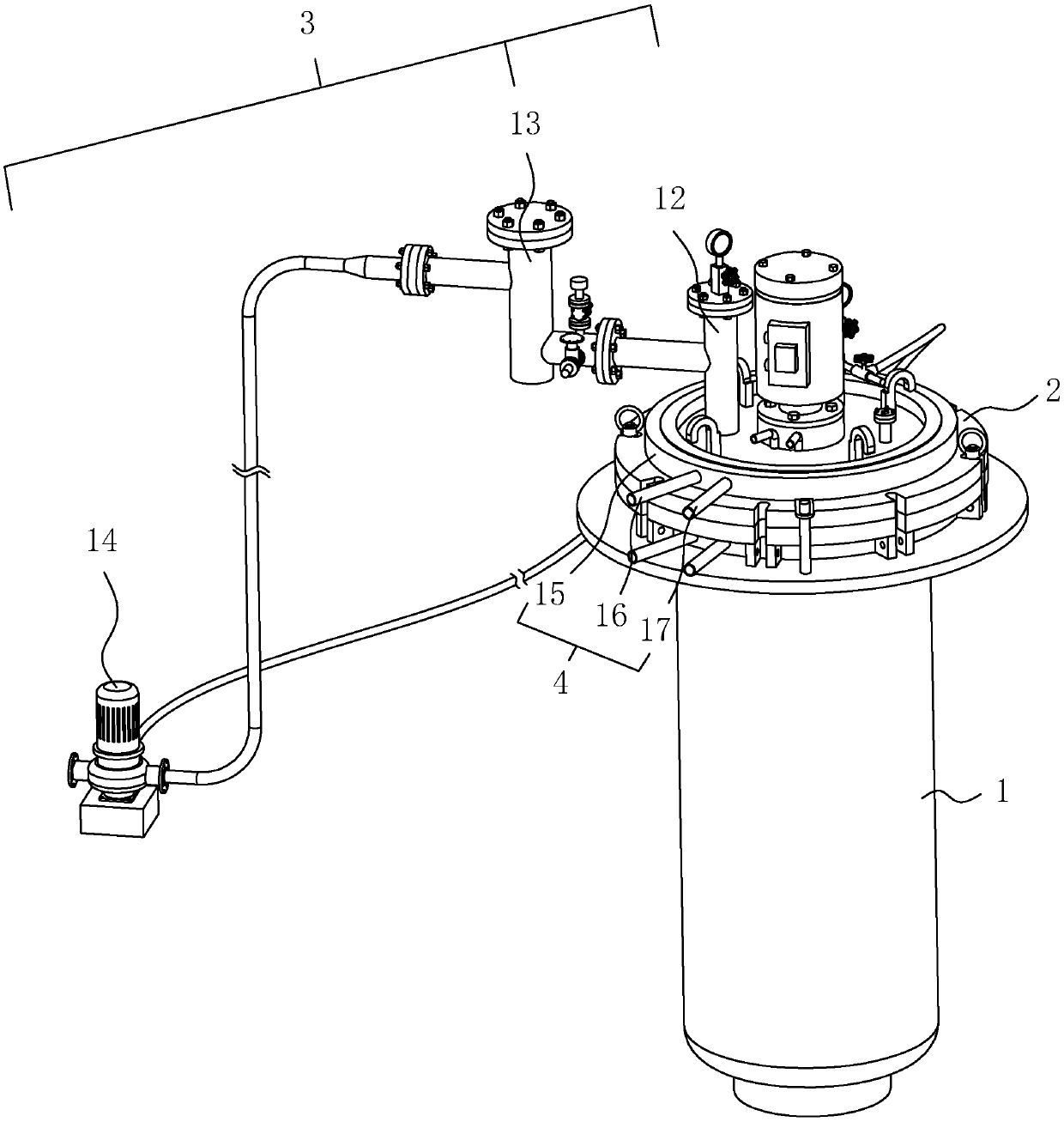

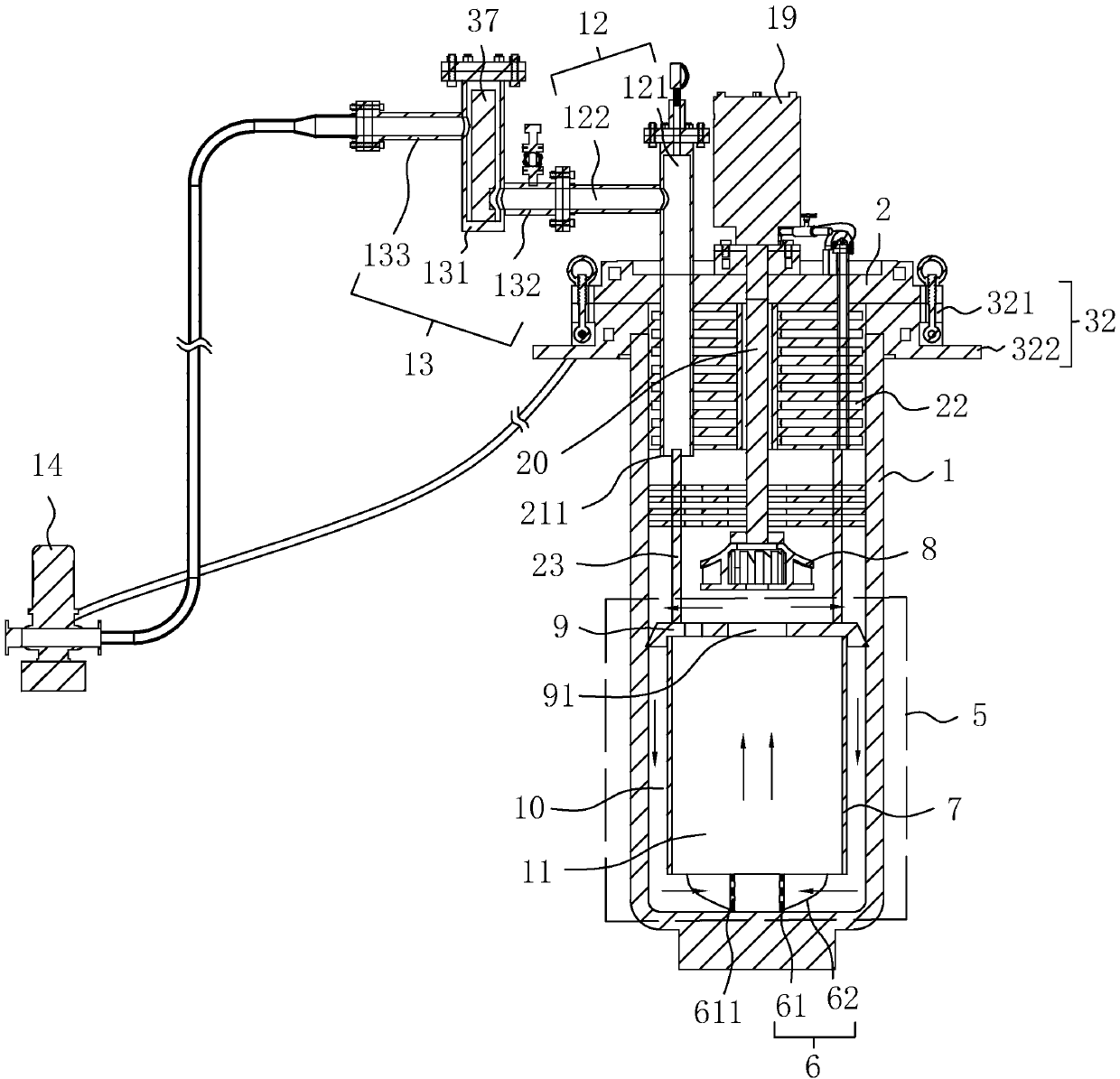

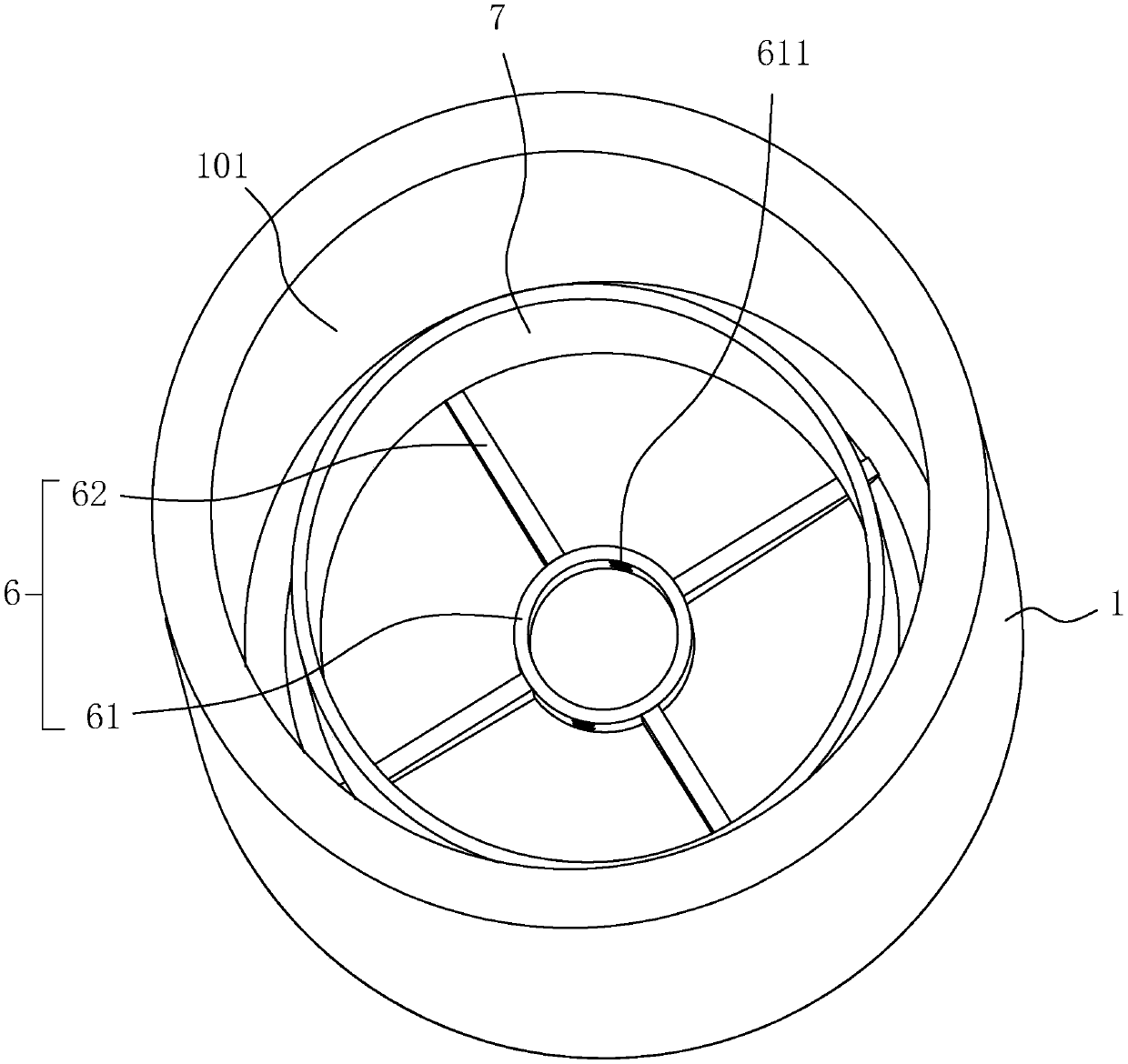

[0049] A reaction device for chemical vapor deposition, such as figure 1 with figure 2 As shown, it includes a furnace tank 1, a furnace cover 2 detachably connected to the furnace tank 1, a heating system (not shown in the figure), a pre-vacuumizing system 3, a cooling system 4 and an air circulation system 5, and the metal powder is preliminarily And the penetrating agent is placed on the bottom of the furnace tank 1, preferably aluminum powder, silicon powder or cobalt powder, then the furnace cover 2 is covered on the furnace tank 1, and the pre-vacuumizing system 3 is started to vacuumize the furnace tank 1 , and then start the heating system to heat the retort 1, and open the cooling system 4 at the same time, which is conducive to the stable temperature rise of the retort 1. When the decomposition temperature of the chloride in the penetrating agent is reached, the chlorine gas reacts with the metal powder to form a gaseous chloride. Chloride follows the route of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com