CD recording/reproducing equipment and method thereof

A technology for recording and reproducing optical discs, which is applied in the directions of recording/reproducing by optical methods, optical recording heads, optical recording carriers, etc., and can solve problems such as difficulty in ensuring assembly accuracy and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

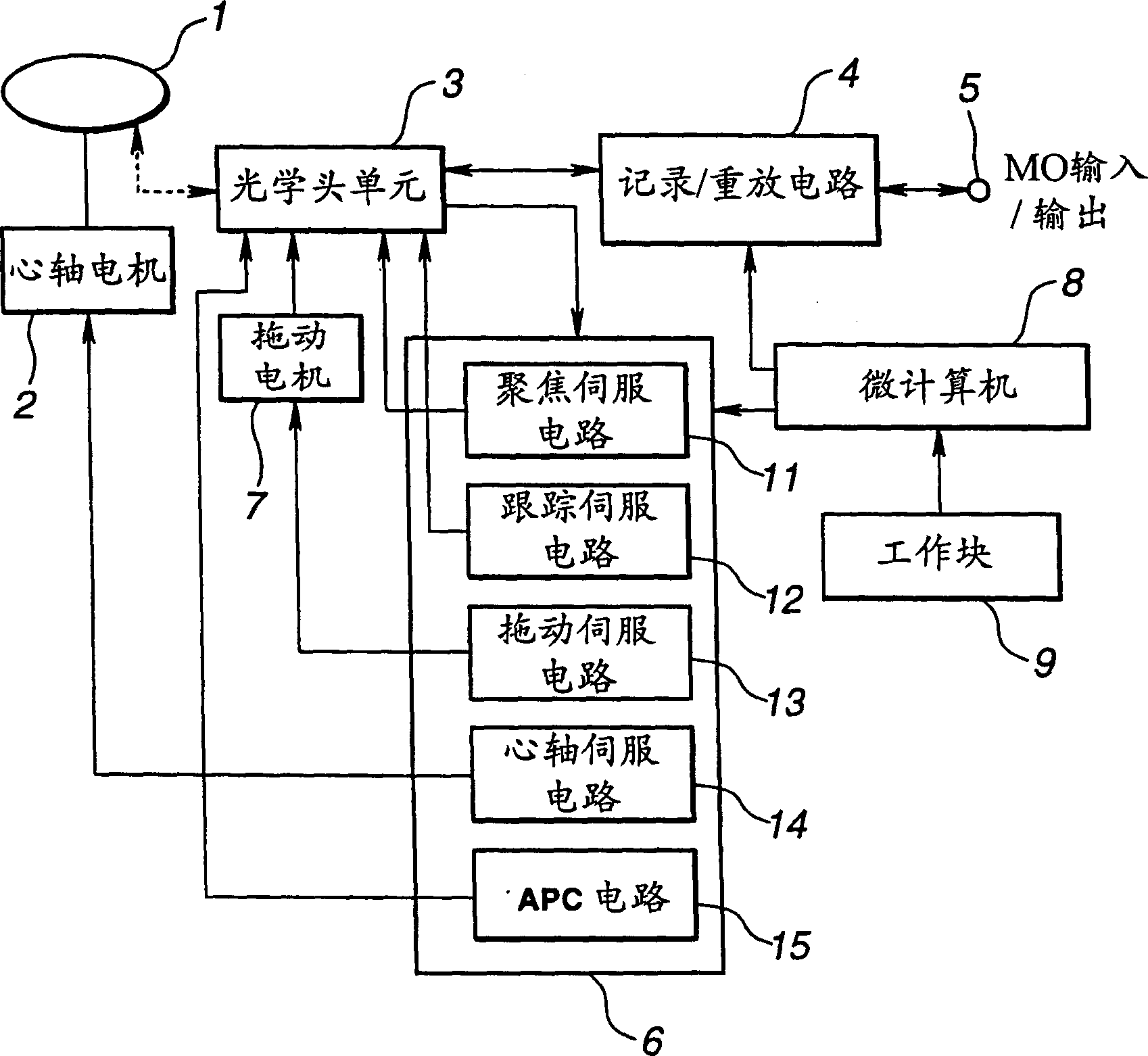

[0031] figure 1 is a block diagram showing the structure of the optical disc recording / reproducing apparatus of the embodiment of the present invention. It should be noted that the following description is made for the case where the magneto-optical disc is used as an optical disc. The magneto-optical disc 1 is rotated by the spindle motor 2 at a predetermined speed. The optical head unit 3 applies a laser beam and a magnetic field to the magneto-optical disc 1 for recording or reproducing data to / from the magneto-optical disc. The recording / reproducing circuit 4 modulates the recording signal applied from the terminal 5 so as to apply the modulated signal to the optical head unit 3; output.

[0032] The servo circuit 6 includes a focus servo circuit 11 , a tracking servo circuit 12 , a drag servo circuit 13 , a spindle servo circuit 14 , and an automatic power control (APC) circuit 15 . The servo circuit 6 reproduces a predetermined error signal from the signal output by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com