Multi-path synchronous control multifunctional vacuum circuit breaker

A vacuum circuit breaker, multi-channel synchronization technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve unsolvable problems such as shaft coordination, achieve stable and precise control, avoid contact damage, and avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

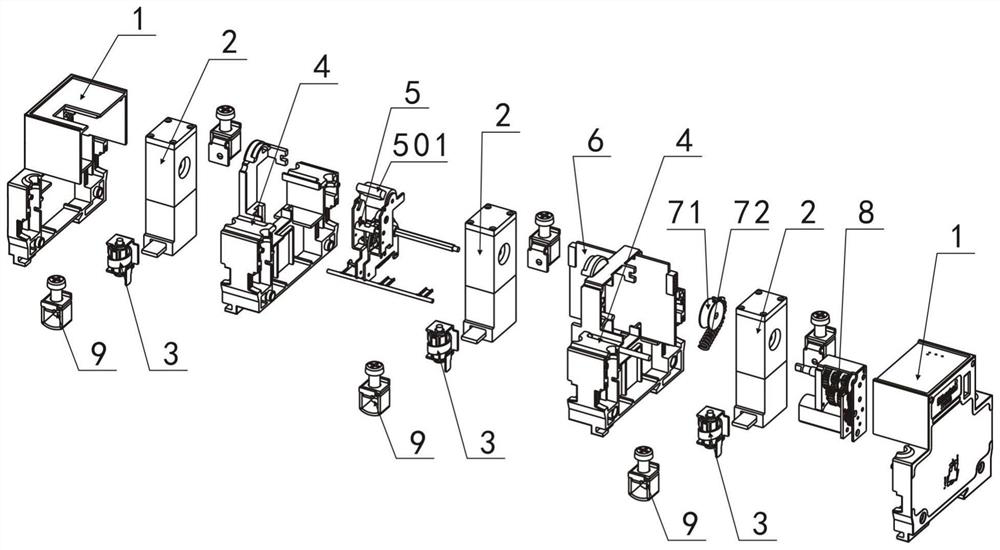

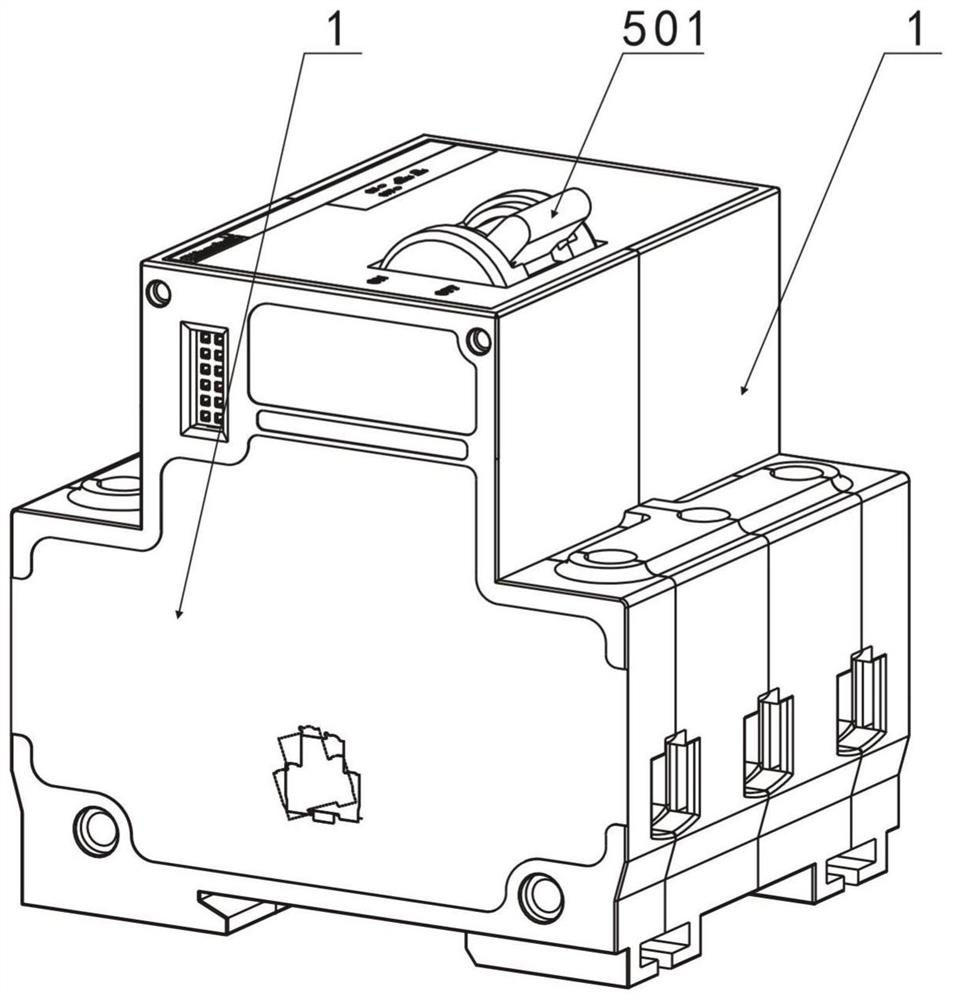

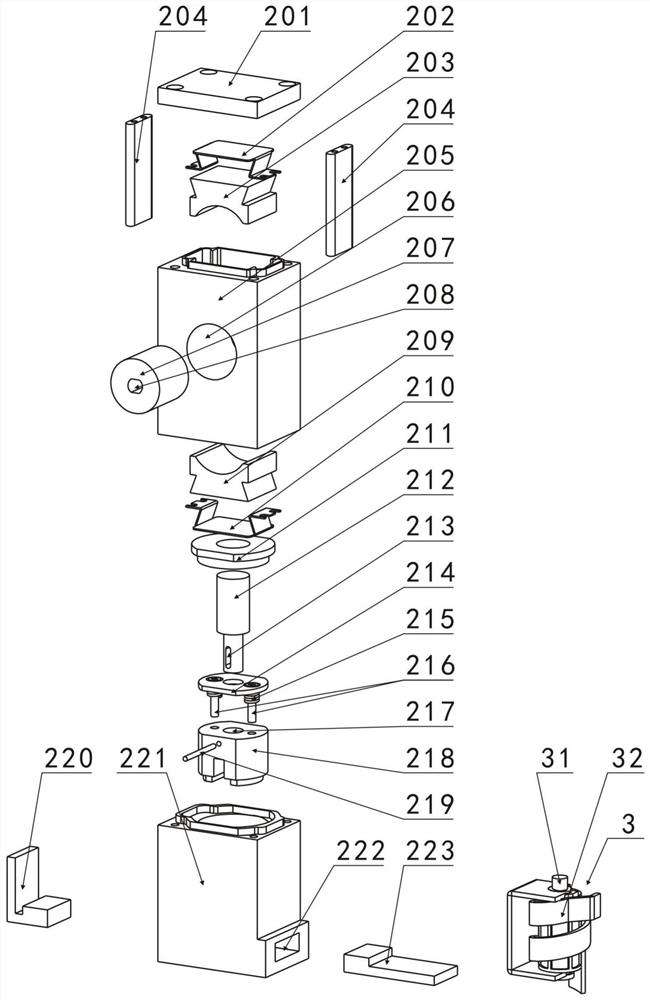

[0041] Such as Figure 1-Figure 6 As shown, the multi-function vacuum circuit breaker with multi-channel synchronous control of the present invention includes a manual switch and an overcurrent protection mechanism 5, a plurality of vacuum switch actuators 2 and a plurality of overcurrent trigger mechanisms 3, and the vacuum switch actuator 2 includes a vacuum cavity (see Figure 3-Figure 5 The first vacuum chamber 221 and the second vacuum chamber 205), the vacuum chamber is installed with the static contact 220 of the incoming line end, the static contact 223 of the outgoing line end and the moving contact 218, and the static contact 220 of the incoming line end The outer end of the outer end and the outer end of the outlet end static contact 223 are respectively placed outside the vacuum chamber, and the moving contacts 218 of the plurality of vacuum switch actuators 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com