High-voltage shore power supply container type heat dissipation structure

A technology of heat dissipation structure and shore power supply, which is applied in the modification of power electronics, electrical equipment structural parts, electrical components, etc., can solve the problem of reducing the service life of shore power supply, damage to cooling air duct components, waste of large area space, etc. problems, to achieve the effect of simple and fast maintenance of cooling fans, consistent air flow in and out, and stable cooling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

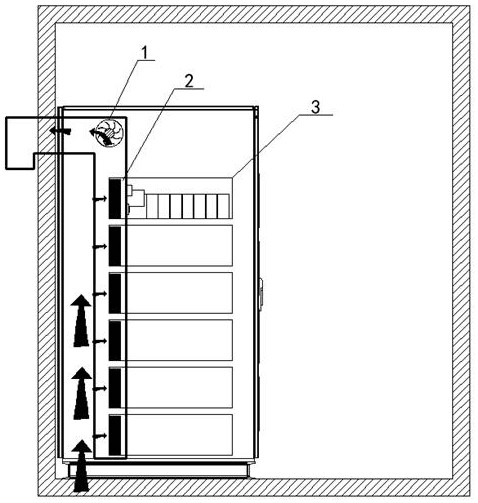

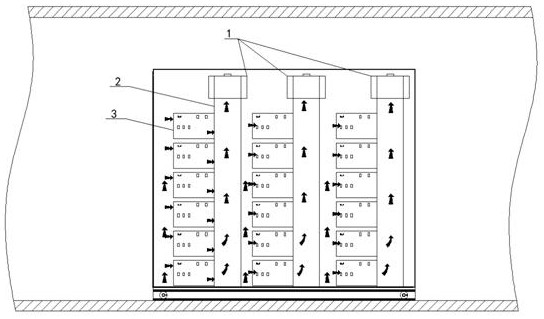

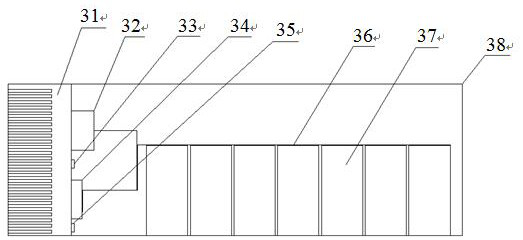

[0029] Such as figure 1 As shown, the present invention includes a container body and 3 rows of unit modules arranged in the container body, each row of unit modules is provided with 6 unit modules, and each row of unit modules 3 is provided with an independent heat dissipation fan 1 and a heat dissipation air duct 2, The heat dissipation fan 1 is fixed on the top of the heat dissipation air duct 2, and the unit module 3 is installed at the opening position of the heat dissipation air duct 2. The heat dissipation fan 1 sucks the external cold air from the air inlet at the bottom of the heat dissipation structure into the left heat dissipation air duct 2, and then passes through the units respectively. The radiator 31 of the module 3 then enters the interior of each unit module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com