Bypass filtering system for filtering impurities in water

A technology of impurity and filter water tank, which is applied in the field of side filter system and can solve problems such as poor filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

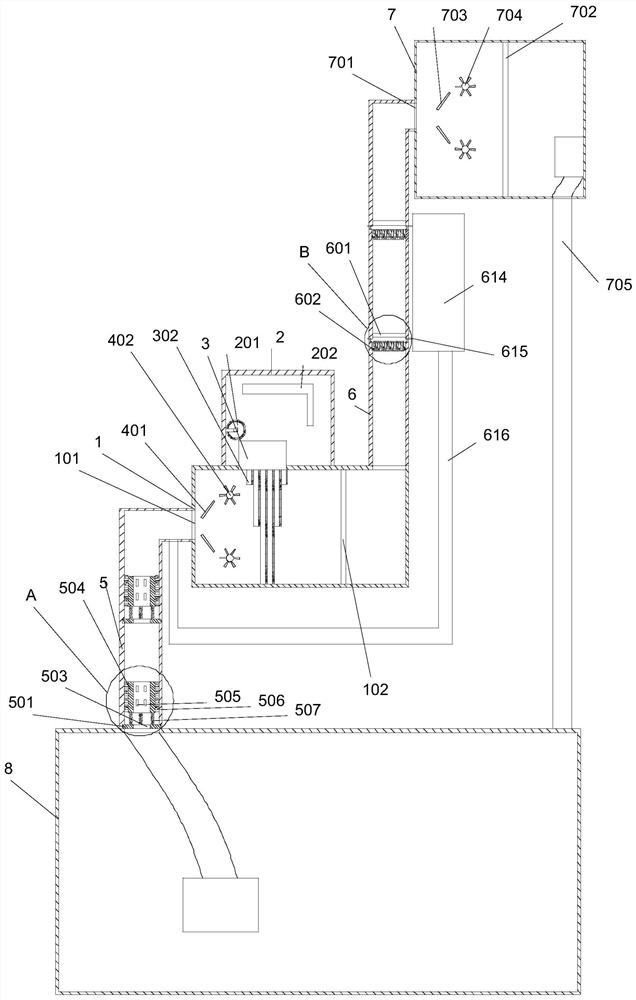

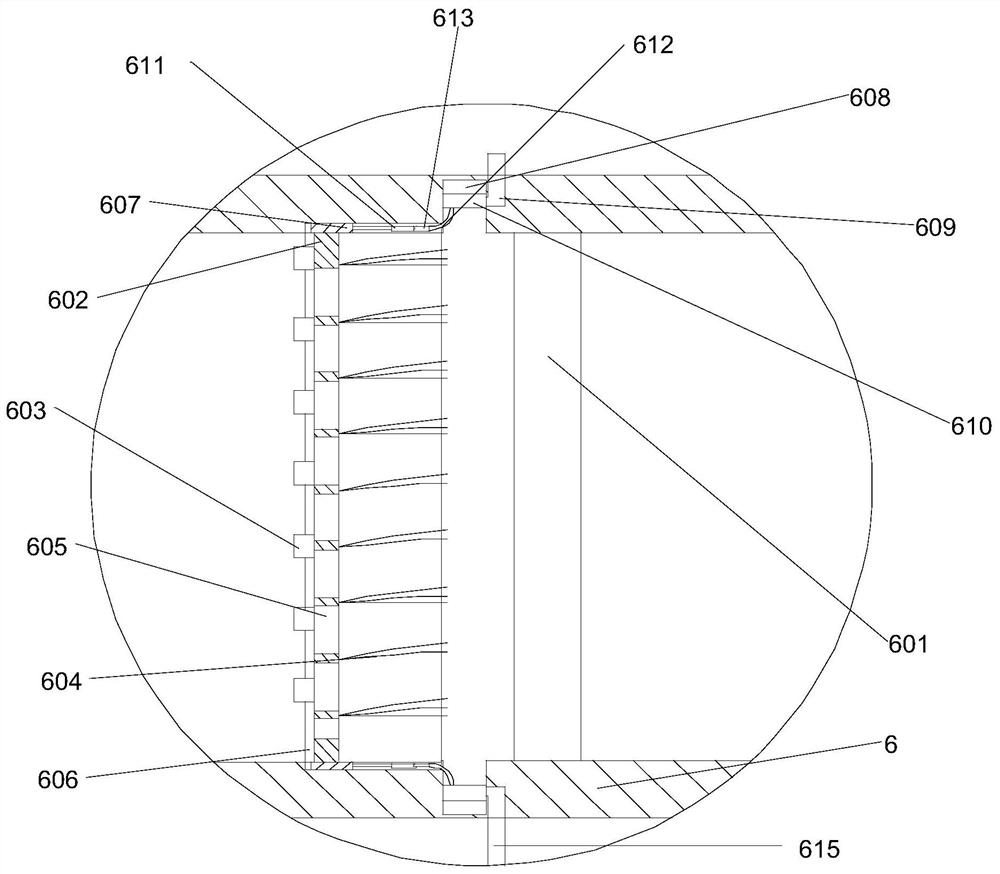

[0042] Such as figure 1 As shown, this embodiment includes a water filter box 1 and a sedimentation tank 2 arranged on the outer side wall of the water filter box 1. A first water inlet hole 101 is opened on the upper side wall of the water filter box 1, and a first water outlet is provided at the bottom of the water filter box 1. The water pipe 6 has a first through hole on the side wall of the filter tank 1, and a second through hole matched with the first through hole on the side wall of the sedimentation tank 2. One side of the water tank 1 is provided with a rotating shaft 3, and a foldable filter assembly is provided on the side wall of the rotating shaft 3. In the initial state, the filter assembly is located in the filter water tank 1, and the filter assembly is completely unfolded to block the cross section of the filter water tank 1. During use, the rotating shaft 3 rotates to drive the filter assembly through the first through hole and the second through hole, so th...

Embodiment 2

[0045] Such as figure 1 , 4 As shown in ~8, this embodiment also includes on the basis of Embodiment 1: the filter assembly includes a plurality of filter units made up of the first rotating cylinder 301 and the fan-shaped filter screen 302, and the end of the fan-shaped filter screen 302 is fixed on the first rotary drum. On the outer wall of the cylinder 301, a plurality of first rotating cylinders 301 are sleeved on the rotating shaft 3 along the axial direction of the rotating shaft 3. There is a third annular chute, a first telescopic rod is provided on the side wall of the rotating shaft 3, and a second slider that slides along the third annular chute is provided at the end of the first telescopic rod, along the circumferential direction of the rotating shaft 3 on its side External teeth 303 are arranged on the wall, and a toothed belt 304 cooperating with the external teeth 303 is provided on its inner wall along the circumference of the first drum 301. One end of the ...

Embodiment 3

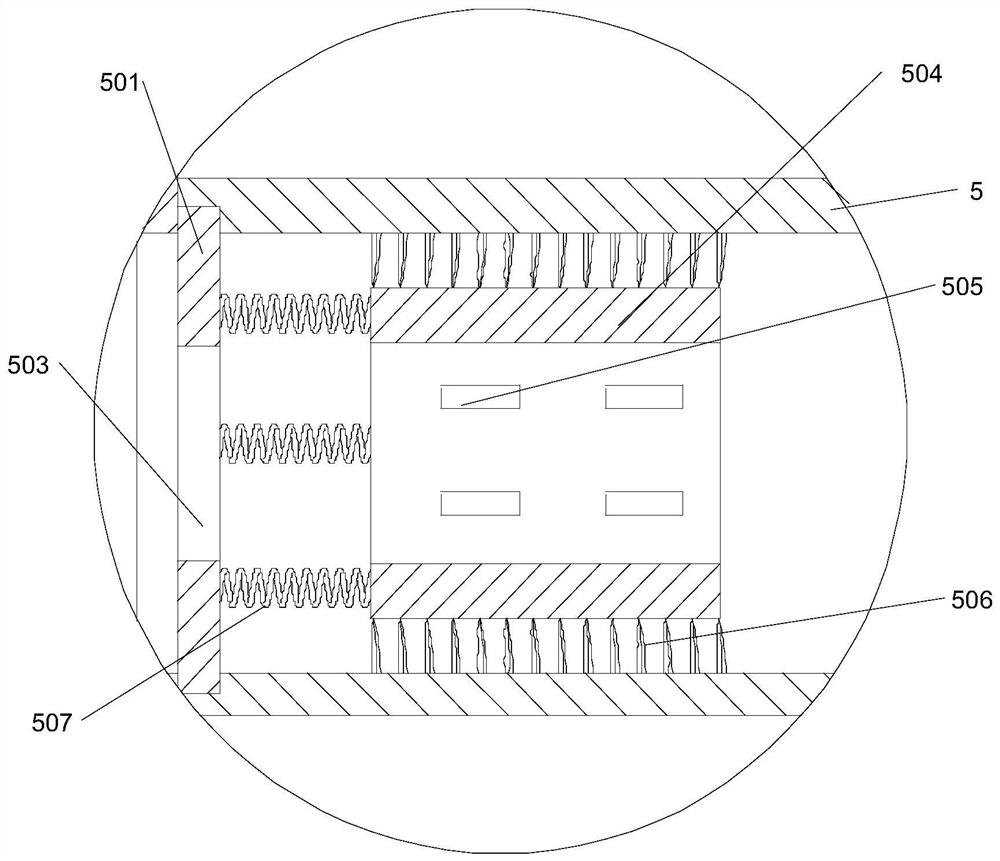

[0052] Such as Figure 1~2 As shown, on the basis of Embodiment 1, this embodiment also includes: a first water inlet pipe 5 communicating with it is provided on the upper side of the first water inlet hole 101, and on the inner side wall of the first water inlet pipe 5 along its circumference There are a plurality of first annular chutes distributed along the first water inlet pipe 5, and along the axial direction of the first water inlet pipe 5, there are a plurality of rotating plates 501 that cooperate with the first annular chute one by one. A third through hole 503 is opened on the top, and a second drum 504 matching the rotating plate 501 is provided on the side of any rotating plate 501 close to the filter tank 1 along the axial direction of the first water inlet pipe 5. The rotating plate 501 and the second rotating drum 504 are connected by a plurality of second springs 507, the two ends of the second rotating drum 504 are open, and a plurality of first springs for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com