Milling tools for high-speed cutting

A milling tool and high-speed cutting technology, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of long adjustment time, unstable structure, complex tool structure, etc., and achieve improved cutting efficiency, simple structure, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The present invention provides a milling cutter for high-speed cutting aiming at the problems of complex structure, long adjustment time and unstable structure of the cutter when the cutter rotates at high speed in the prior art.

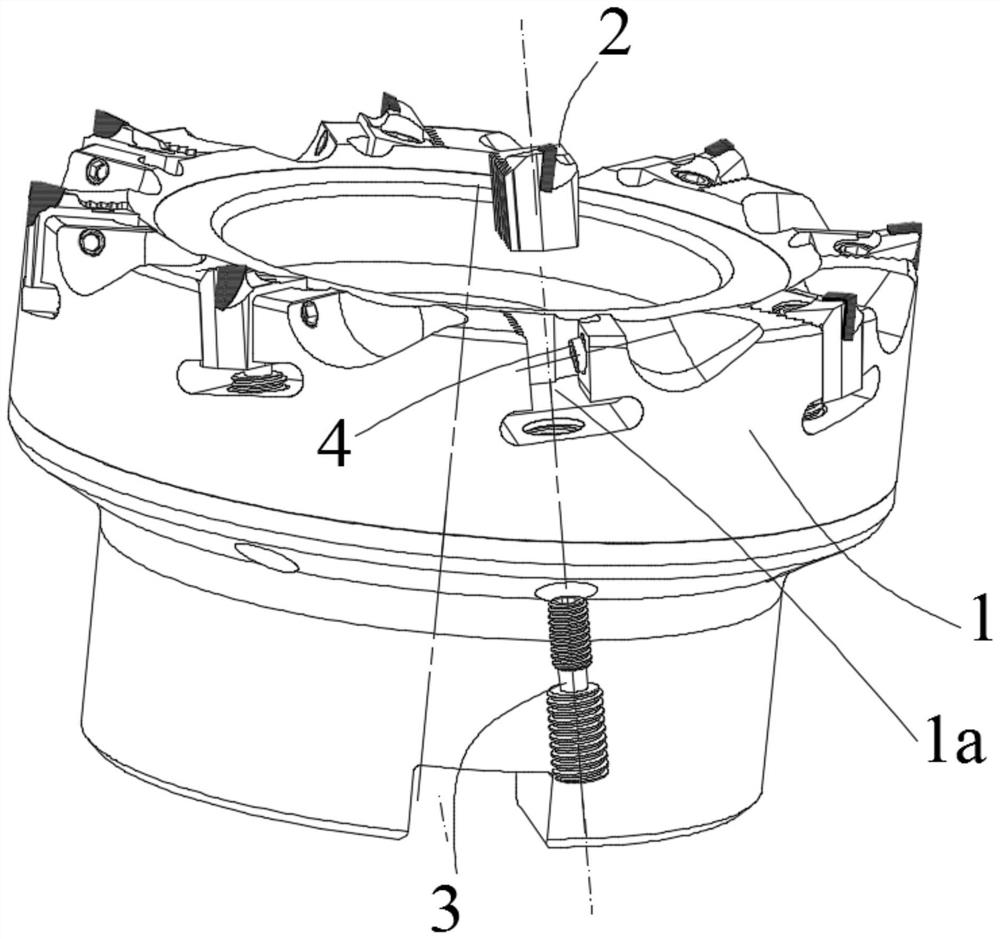

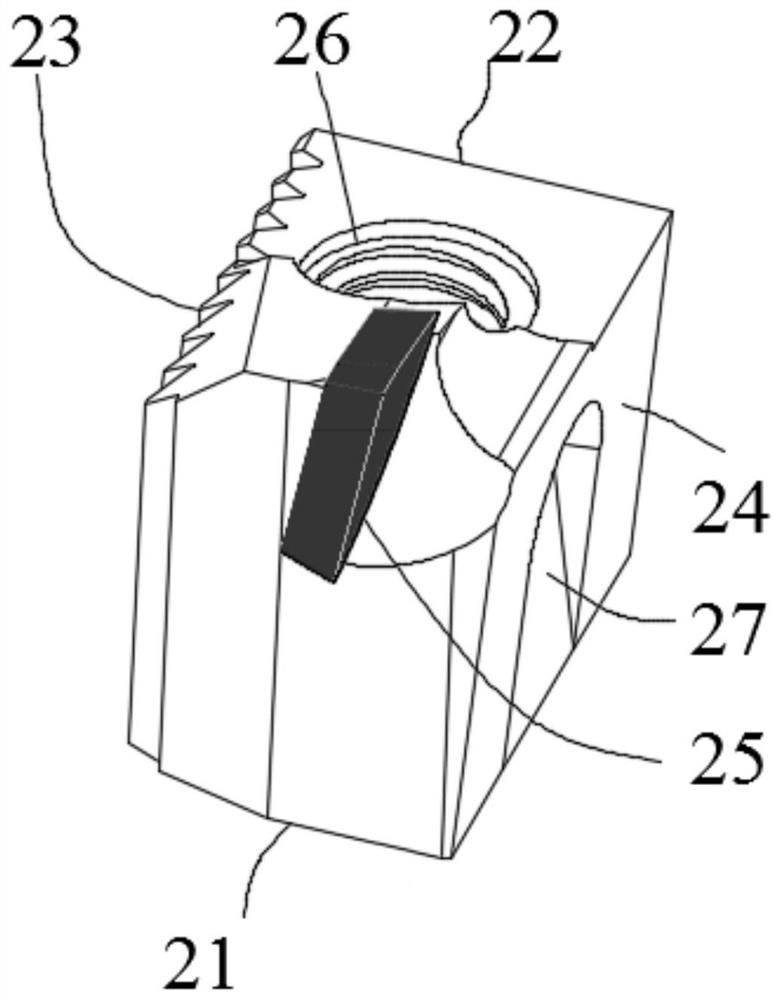

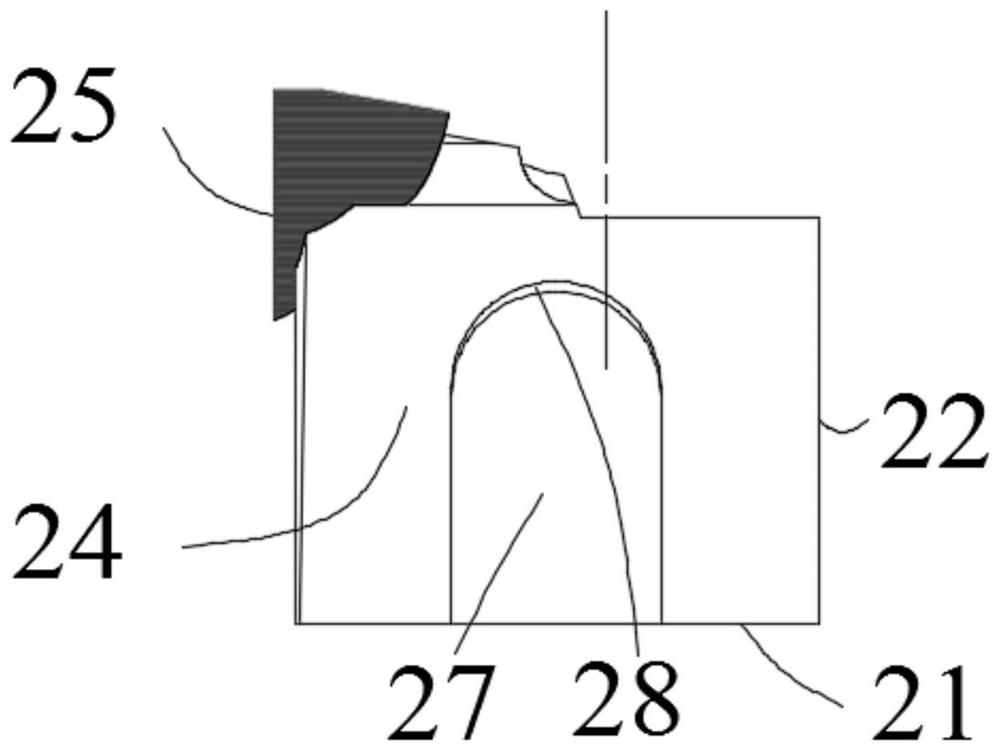

[0040] Such as Figure 1 to Figure 13As shown, the embodiment of the present invention provides a milling tool for high-speed cutting, including: a cutter body 1, the cutter body 1 is a disc-shaped cutter body, and a plurality of sipes 1a are uniformly arranged on the cutter body 1, The sipe 1a is used to install a cutting unit; the cutting unit includes a tool holder 2, a drive screw 3 and an auxiliary compression screw 4; each of the sipe 1a is composed of a sipe axial surface 11, a sipe radial Surface 12, the first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap