Shut-off synchronous glue sealing nozzle

A technology of sealing and injecting glue, which is applied in the field of synchronous sealing and sealing nozzles, which can solve the problems of speeding up the production cycle and easy overflow of glue, and achieve the effects of speeding up the production cycle, simple replacement, and improving production stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

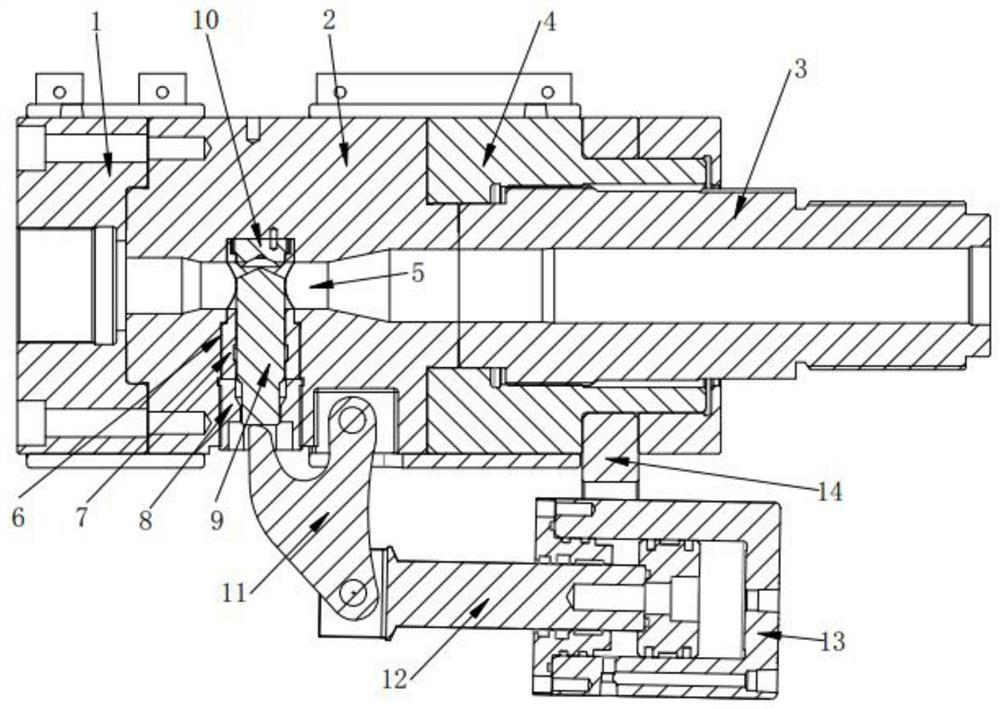

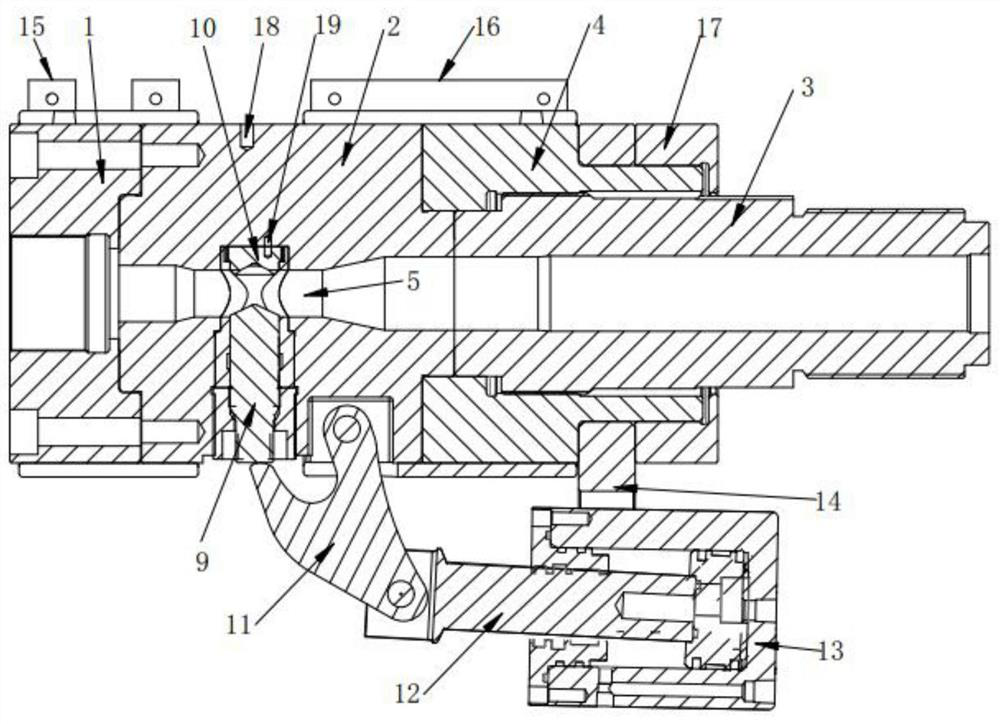

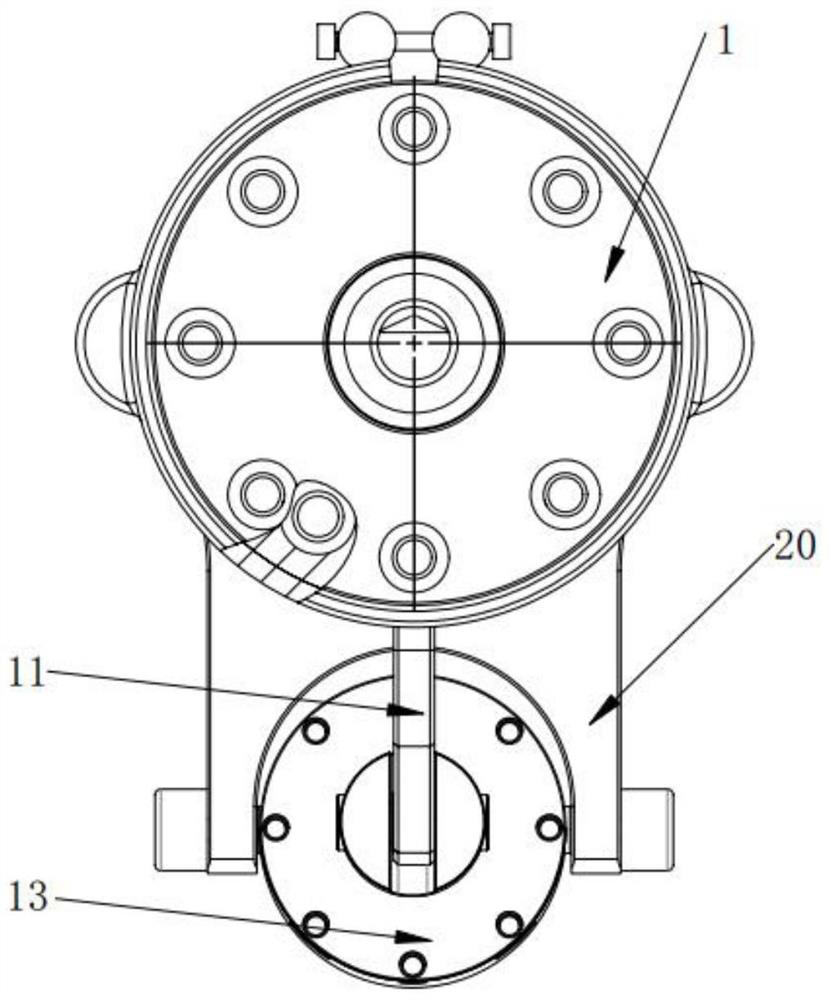

[0038] see figure 1 and figure 2 as shown, figure 1 It is a schematic diagram of the cross-sectional structure of the closed synchronous sealing nozzle when it is about to be completely closed. When the injection valve core is closed, the injection molding machine can perform other actions such as sol, mold opening, and ejection; and figure 2 It is a schematic cross-sectional structure diagram of the shut-off synchronous sealing nozzle when it is in the open state. At this time, the injection molding machine can perform injection and retraction actions. This embodiment provides a shut-off synchronous glue sealing nozzle, which includes a nozzle, a nozzle connecting flange 1, a nozzle middle seat 2, a material pipe connector 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com