A milk tea cup conveying line in a fully automatic milk tea machine

A milk tea cup and milk tea machine technology, which is applied to conveyor objects, transportation and packaging, packaging and other directions, can solve the problem of low conveying efficiency, and achieve the effects of cost saving, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

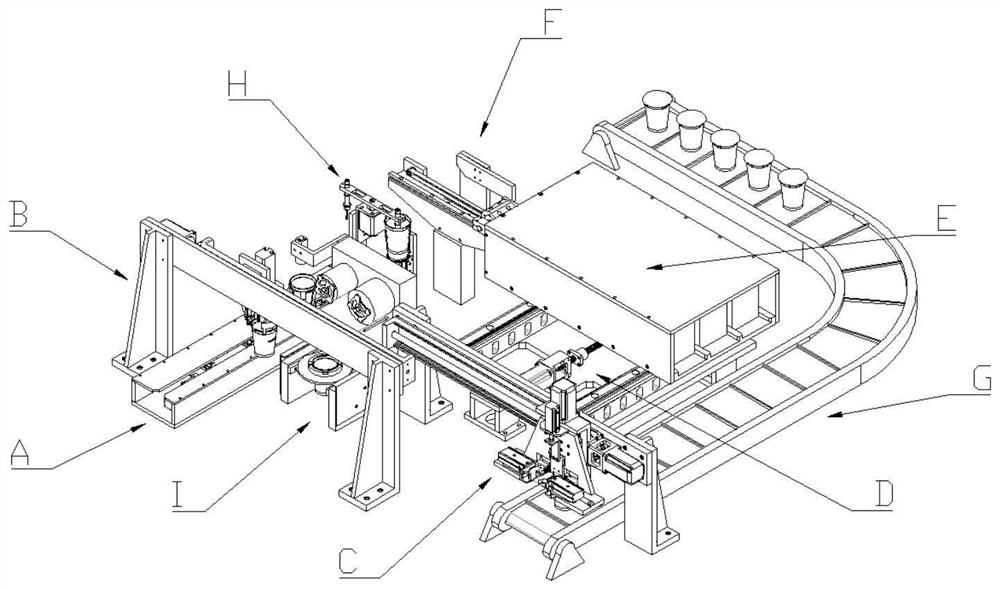

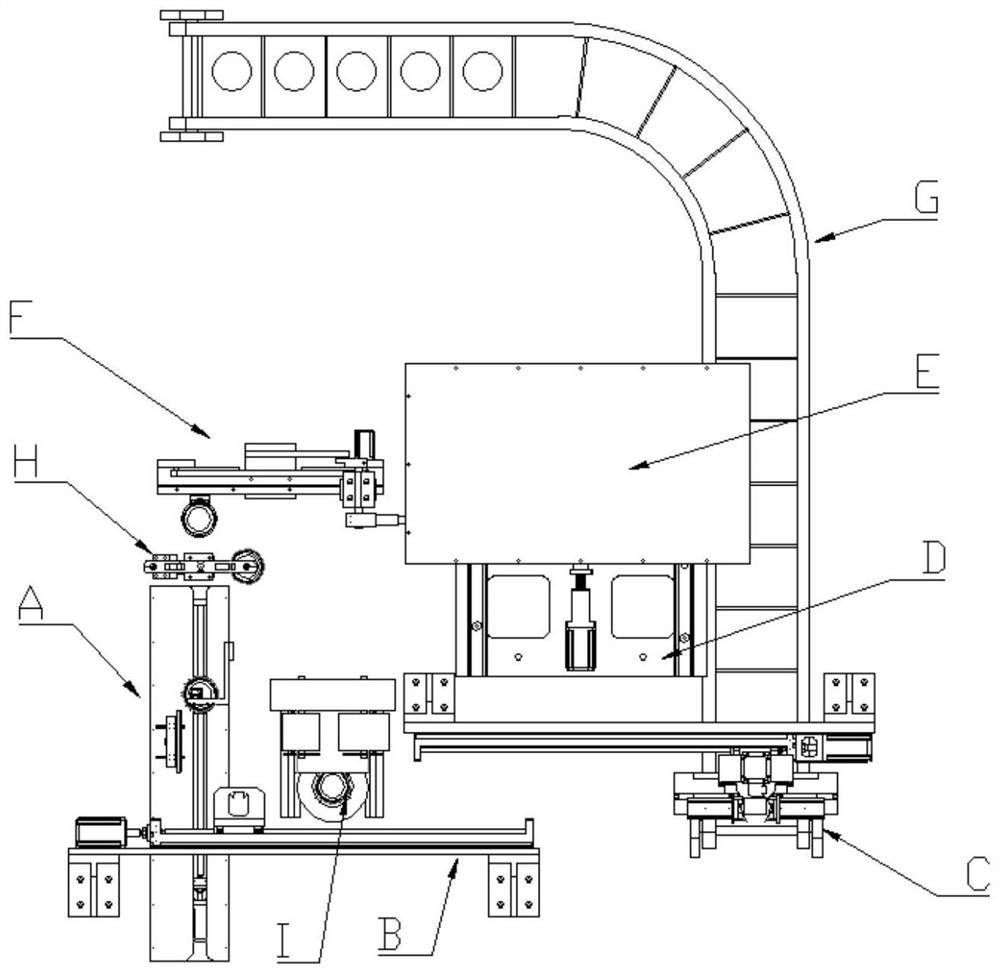

[0044] see Figure 1-Figure 41 , the milk tea cup conveying line in the automatic milk tea machine of the present invention comprises a cup-taking system and a conveying system for conveying the milk tea cups, wherein the cup-taking system is used to take out the milk tea cups one by one; the conveying system is used to The milk tea cups taken out by the cup taking system are transported to each processing station of the milk tea processing equipment.

[0045] The specific structure of the cup taking system and the conveying system will be described below.

[0046] (1), cup taking system

[0047] The cup taking system in the present invention includes a cup sending device E and a cup taking device F.

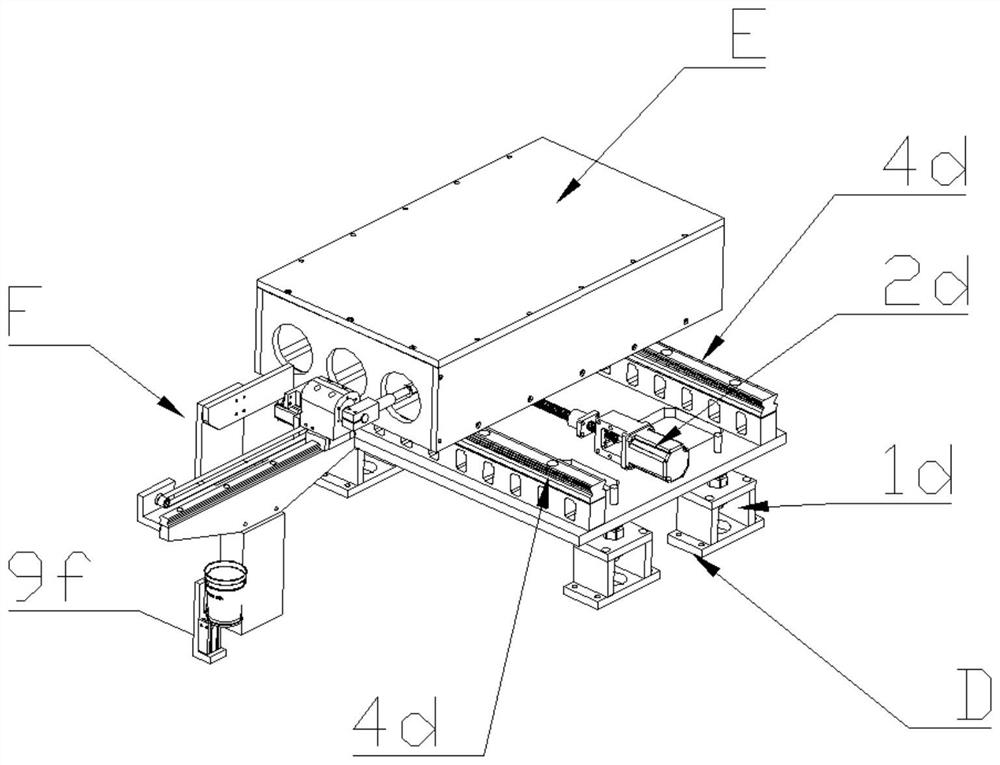

[0048] see Figure 3-Figure 15 , the cup feeding device E includes a fourth frame 5e, a plurality of cup feeding modules arranged on the fourth frame 5e, and is used to drive the movement of the fourth frame 5e to promote the movement of the fourth frame 5e. The cup outlet o...

Embodiment 2

[0109] This embodiment is different from Embodiment 1 in that: the milk tea cup conveying driving mechanism includes a driving cylinder, the cylinder body of which is installed on the first frame 1a, and the telescopic rod of the driving cylinder is connected to the conveying seat 3- 1 connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com