Camellia distillate liquor and preparation method thereof

A technology for distilling liquor and camellia, which is applied in the field of brewing, can solve the problems of increased production workload, time and economic cost, waste of nectar elution, and numerous sterilization procedures, and achieves simple brewing procedures and operations, increased sugar content, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

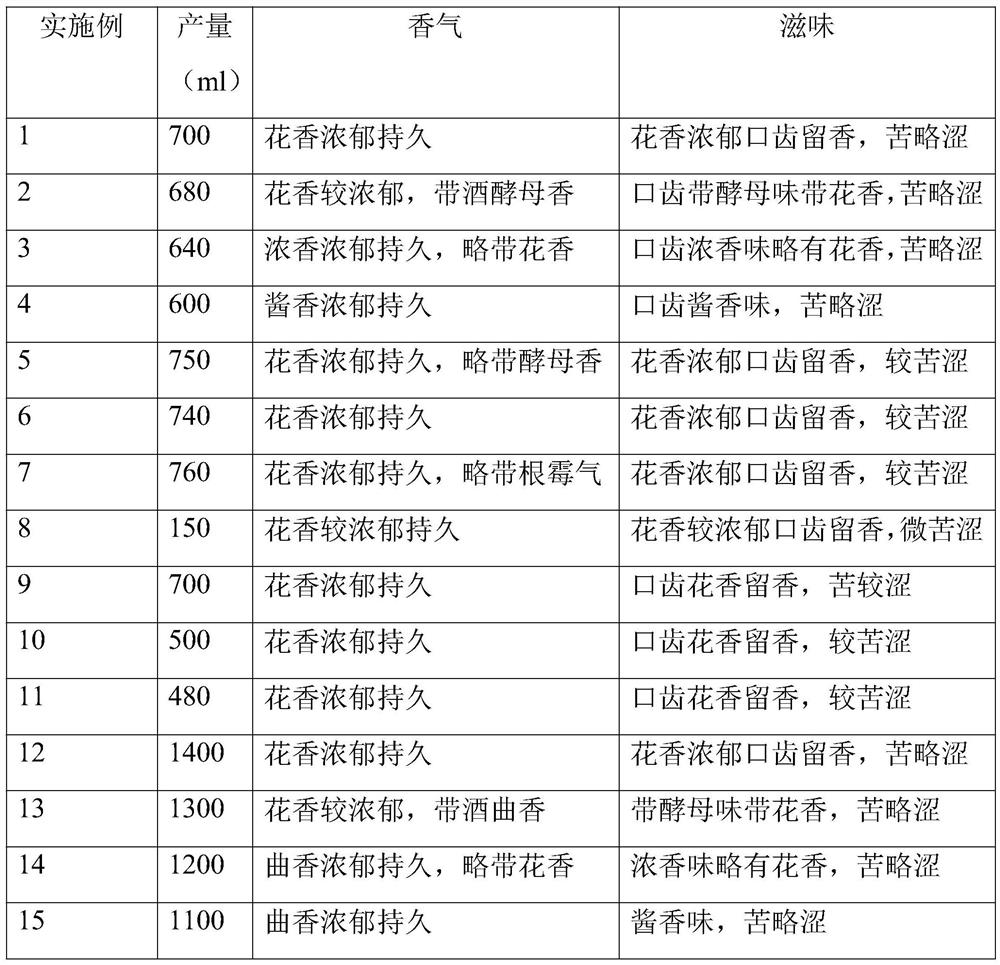

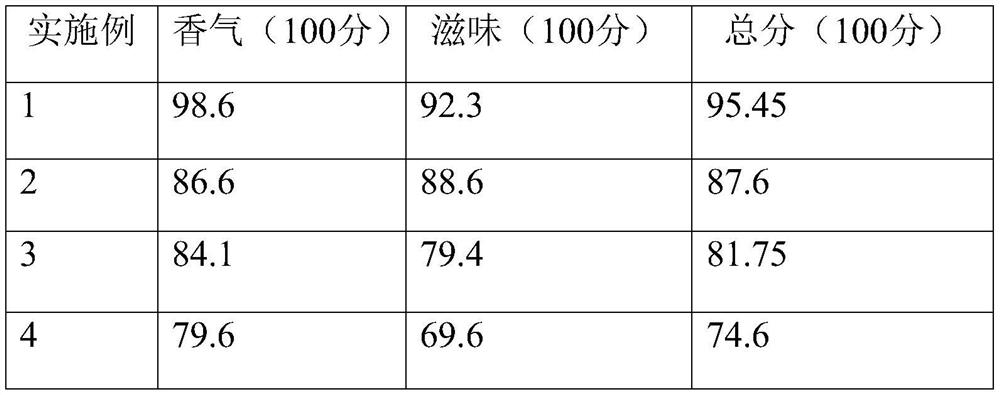

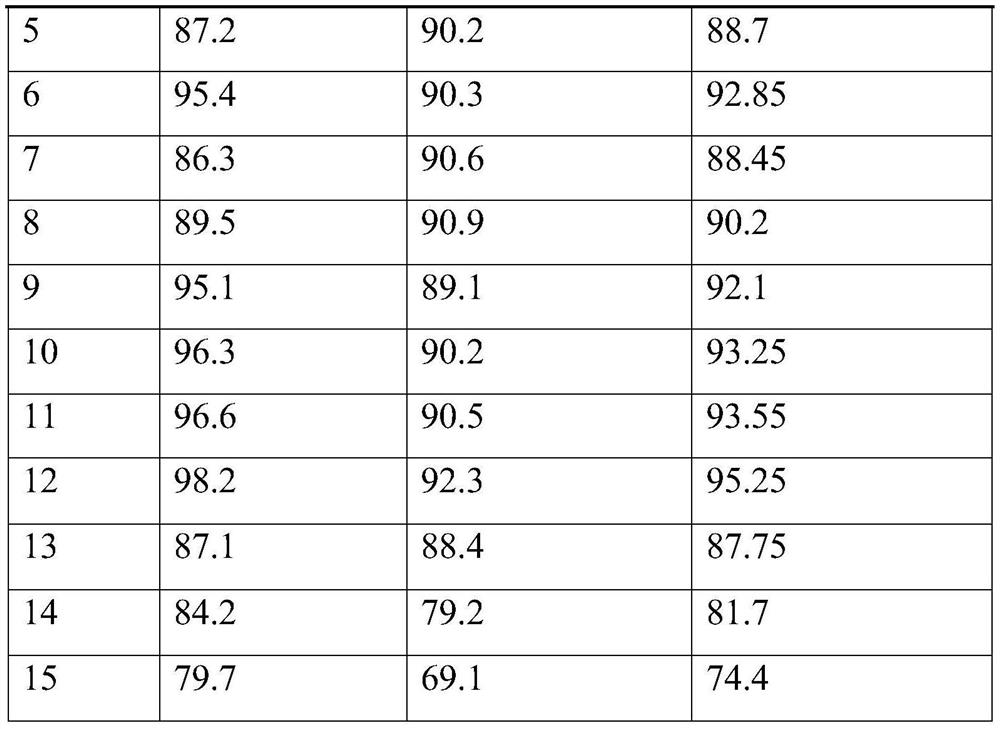

Embodiment 1

[0074] On October 15, 2019, weigh 20 kg of fresh camellia, add 20 g of cellulase, 100 g of rhizopus, and 20 g of Angelica rice wine koji, mix well, put it into a stainless steel airtight tank (temperature is 25°C), cover it, and seal it fermentation. On December 15, 2019, the obtained fermented mixture was placed in a wine still for initial distillation to obtain 4000ml of 10% liquor (primary distilled wine), and then the obtained 10% liquor (primary distilled wine) was poured into the wine still Carry out re-distillation, stop heating when the alcohol content drops to 50 degrees, get 53 degrees of liquor (re-distilled wine) 700ml, which is the camellia distilled wine. It is also possible to mix the obtained re-distilled wine with pure rice wine in a certain ratio to obtain the final camellia wine product.

Embodiment 2

[0076] On October 15, 2019, weigh 20 kg of fresh camellia, add 20 g of cellulase, 100 g of rhizopus, and 20 g of Angelica Baijiu Wang koji, mix well, put it into a stainless steel airtight tank (temperature is 25 ° C), cover the lid, Sealed fermentation. On December 15, 2019, the obtained fermented mixture was placed in a wine still for primary distillation to obtain 3900ml of 10% liquor (primary distilled wine), and then the obtained 10% liquor (primary distilled wine) was poured into the wine still Carry out re-distillation, stop heating when the alcohol content drops to 50 degrees, get 53 degrees of liquor (re-distilled wine) 680ml, which is the camellia distilled wine. It is also possible to mix the obtained re-distilled wine with pure rice wine in a certain ratio to obtain the final camellia wine product.

Embodiment 3

[0078] On October 15, 2019, weigh 20 kg of fresh camellia, add 20 g of cellulase, 100 g of rhizopus, and 2000 g of Luzhou-flavor koji, mix well, put it into a stainless steel airtight tank (temperature is 25 ° C), cover the lid, and seal it fermentation. On December 15, 2019, the obtained fermented mixture was placed in a wine still for initial distillation to obtain 3700ml of 10% liquor (primary distilled wine), and then the obtained 10% liquor (primary distilled wine) was poured into the wine still Carry out re-distillation, stop heating when the alcohol content drops to 50 degrees, get 53 degrees of liquor (re-distilled wine) 640ml, which is the camellia distilled wine. It is also possible to mix the obtained re-distilled wine with pure rice wine in a certain ratio to obtain the final camellia wine product.

[0079] Among them, the Luzhou-flavor koji is Yiqian’s handmade Luzhou-flavor koji, and the recommended ratio in the instructions is 1:10. Therefore, the addition amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com