Device and method for correcting deformed container

A technology of a correction device and a container, applied in the field of restoration and plastic surgery, can solve the problems of wasting time, manpower and material resources, and achieve the effects of improving work efficiency, saving manpower and material resources, and facilitating repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

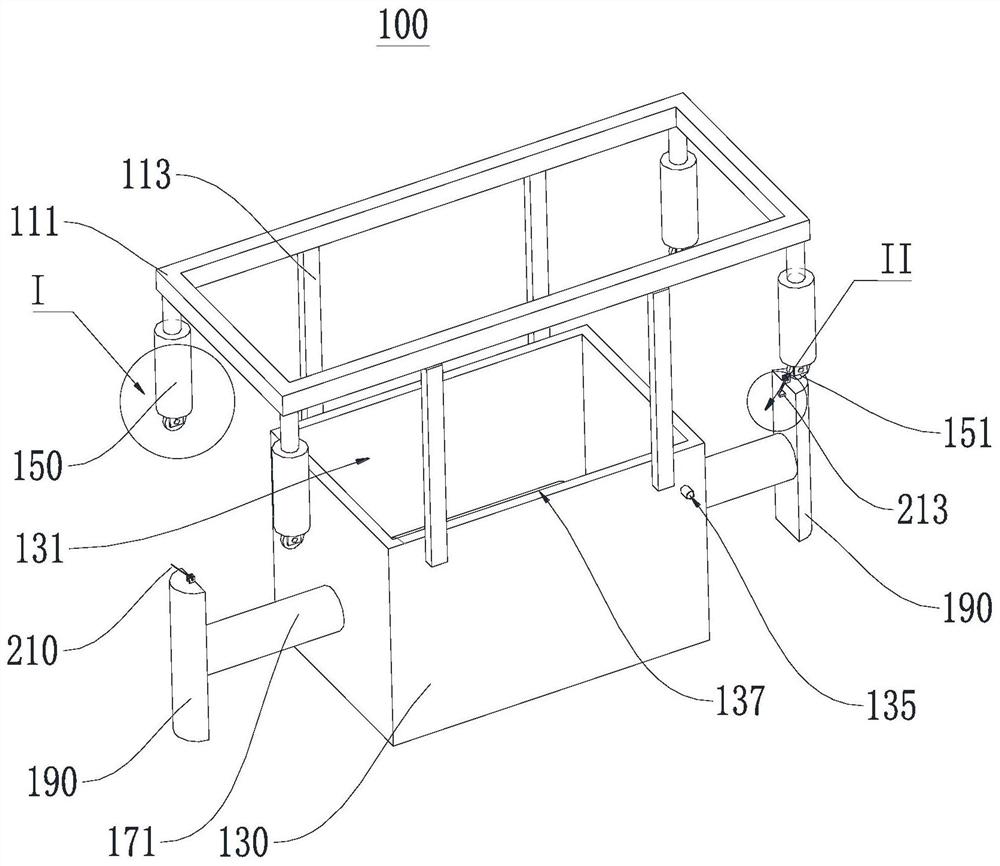

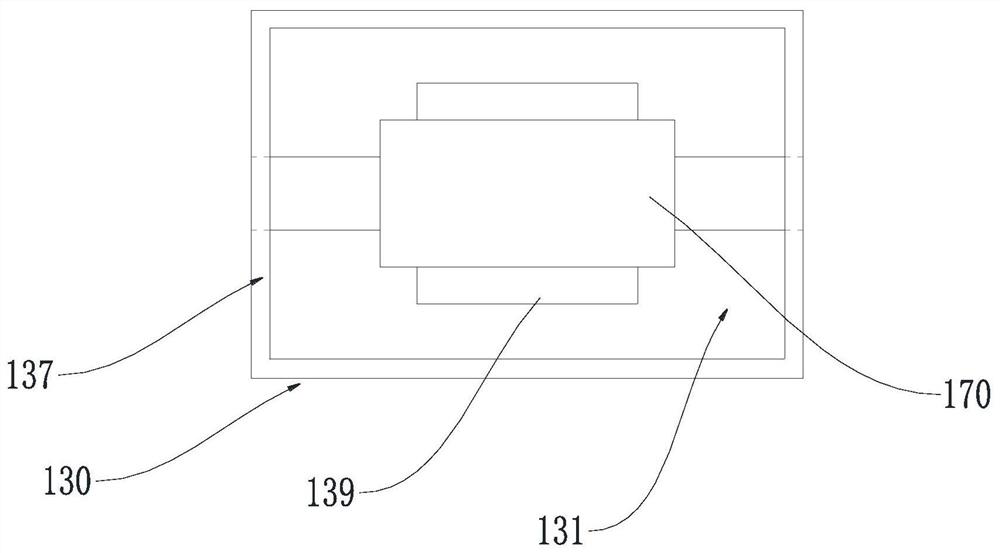

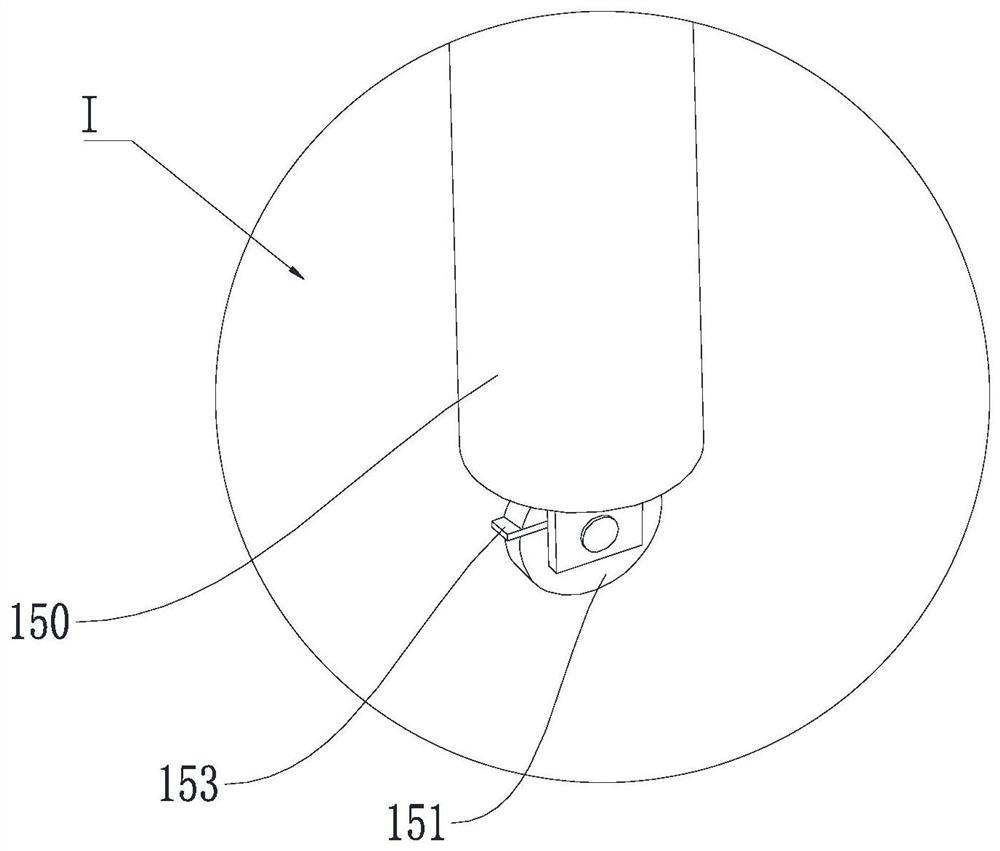

[0043] Please refer to figure 1 , figure 1Shown is a schematic structural view of a deformation container correction device provided by this embodiment. A deformation container correction device 100 includes a fixed frame 110 , a temperature control box 130 , a lifting assembly 150 , a power assembly 170 and at least two restoring parts 190 . Both the lifting assembly 150 and the temperature control box 130 are fixedly installed on the lower part of the fixed frame 110. The inner side of the temperature control box 130 is provided with an accommodation chamber 131, and the power assembly 170 is located in the accommodation chamber 131. When calibrating the reactor, it is necessary to first adjust the reaction The temperature control box can prevent the power unit from being damaged due to overheating during the working process. The two ends of the power assembly 170 run through the casing of the temperature control box 130, and both sides of the casing are respectively provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com