A track-changing anti-twist wire rope braiding machine

A rope braiding machine and track technology, which is applied in the field of track-changing anti-twist wire rope braiding machines, can solve problems such as unstable pay-off tension, small torque, uncontrollable pay-off tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

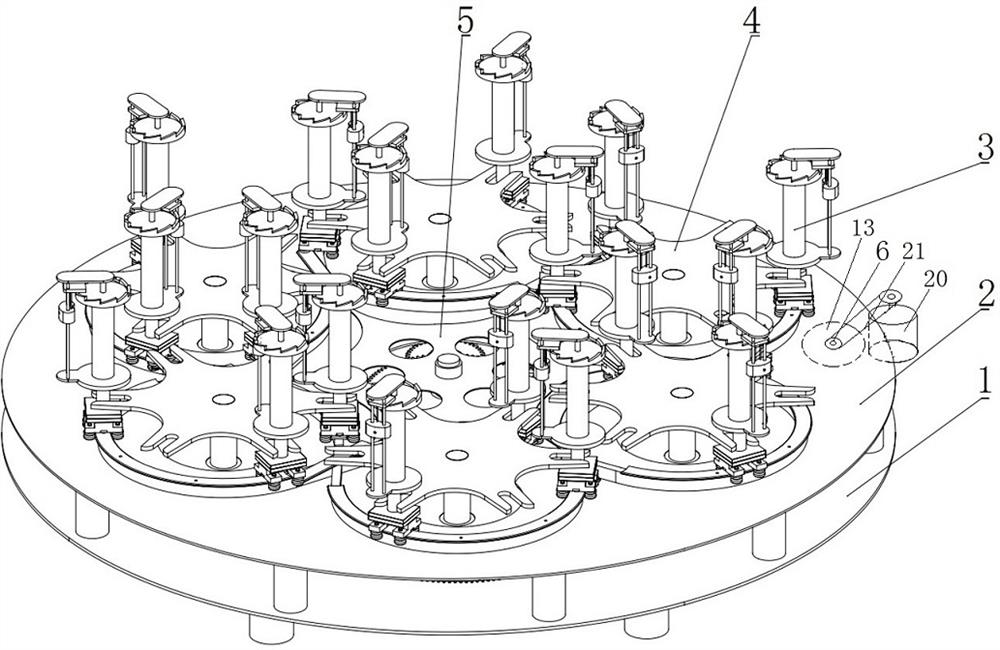

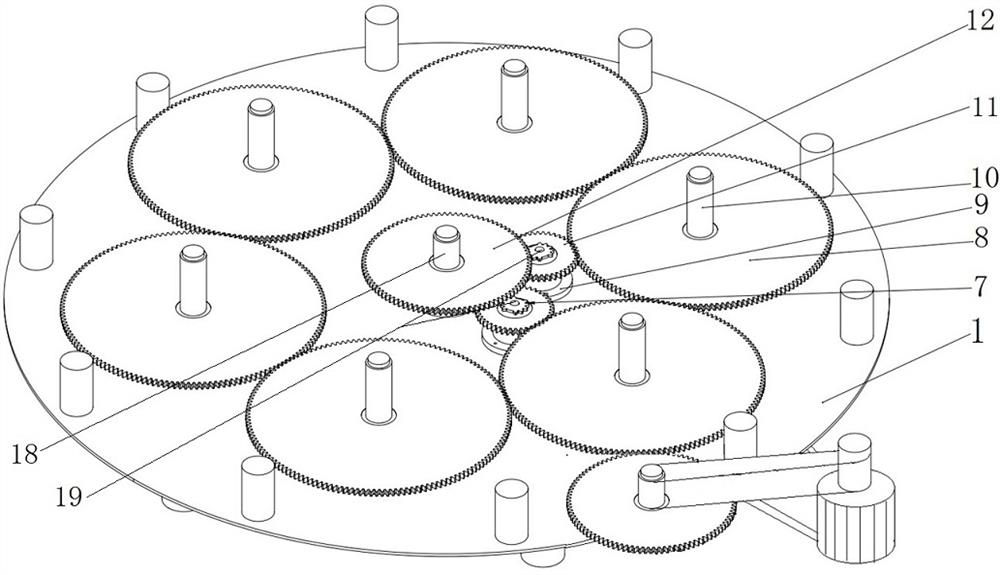

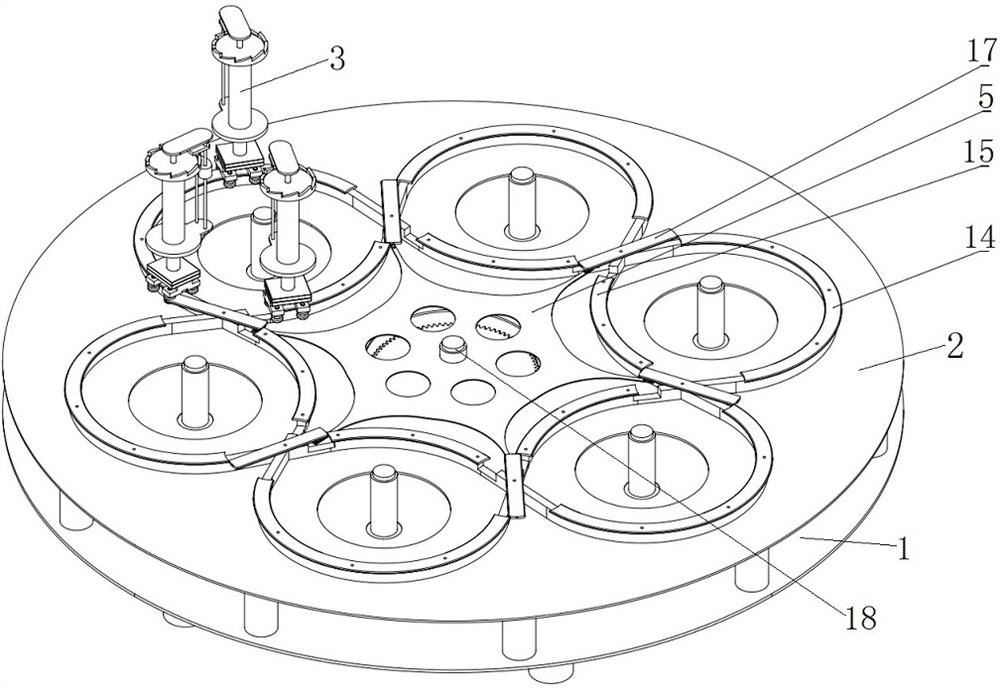

[0047] Refer to attached Figure 1-10 , a track-changing anti-twist wire rope braiding machine is composed of a base part, a gear transmission part, a drum walking track part, a fork part, and a drum winding part 3 (drum assembly):

[0048] The base part has a base 1, and the base 1 is provided with a circular steel plate 1-2. The base 1 is welded by a circular steel plate 1-2 and six cylindrical support columns 1-1. Six groups of base mounting holes 1-4 for the first transmission shaft (main shaft) are evenly distributed on the circular steel plate 1-2 of the machine base, and are used for installing 10 seats of the first transmission shaft (transmission shaft). There are 10 support columns 1-3 distributed on the edge of the circular steel plate for supporting the running track. The middle part of the circular steel plate 1-2 is provided with a central mounting hole 1-5 for mounting the central gear shaft 8 . The lower part of the annular steel plate 1-2 is welded with six...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com