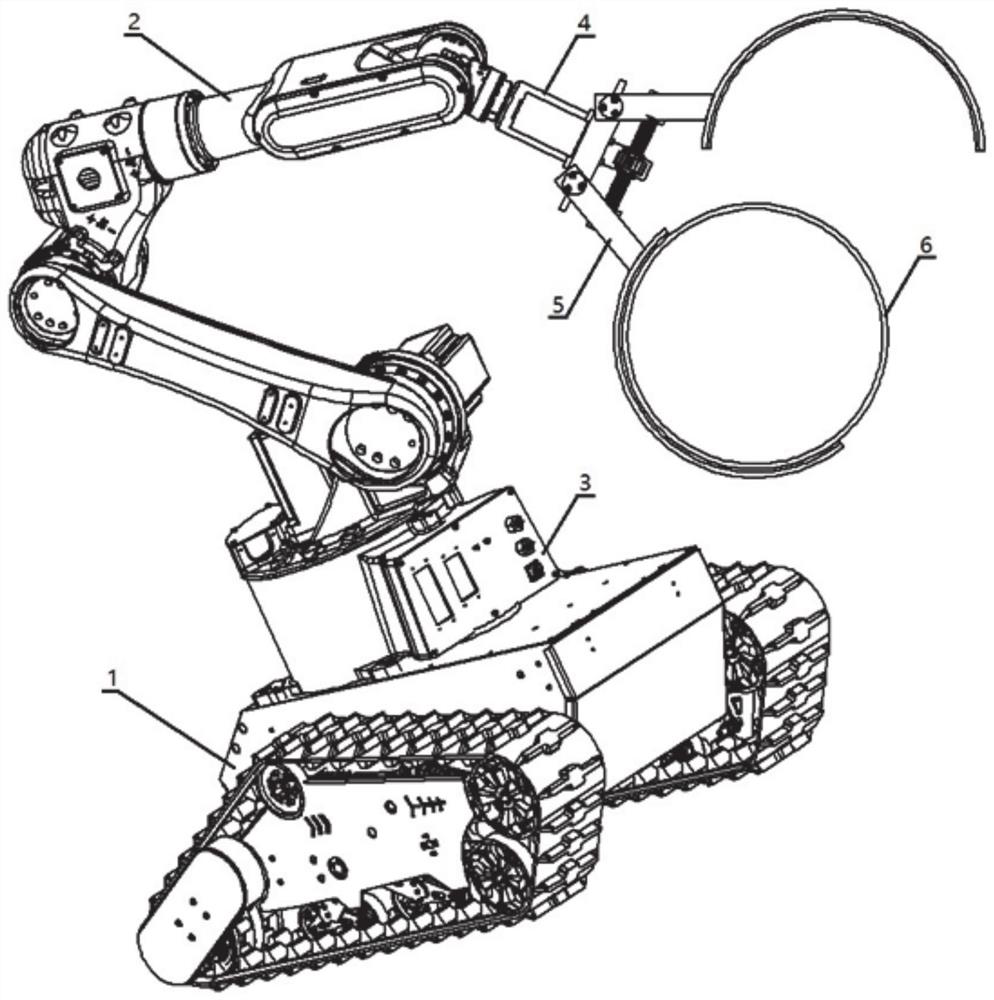

Pipeline leaking stoppage robot and working method

A technology of robots and pipelines, which is applied to pipe components, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as low efficiency and hidden dangers to personal safety, and achieve high work efficiency and avoid threats to personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

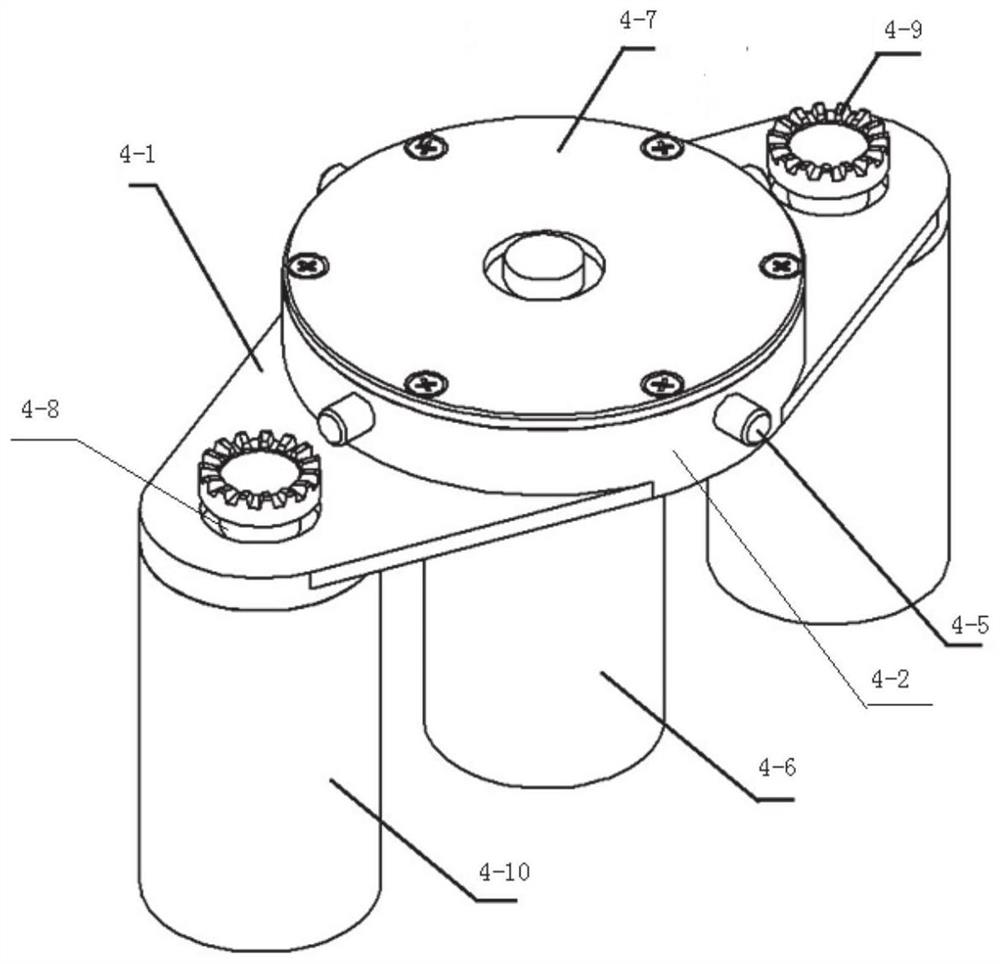

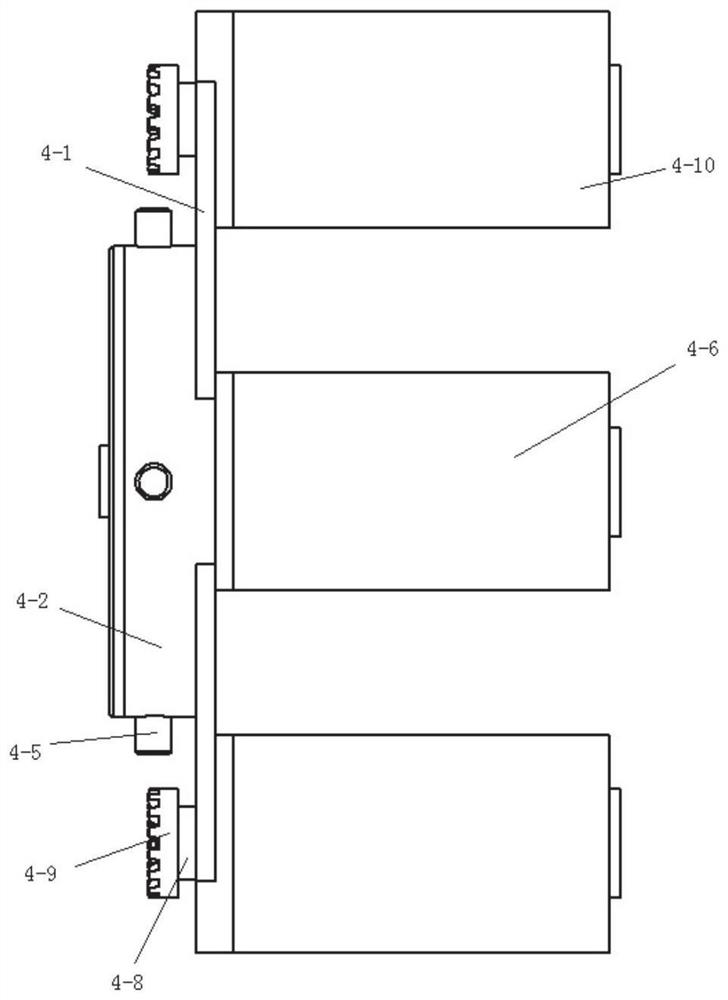

[0064] This embodiment discloses a working method of the pipe leakage plugging robot described in Embodiment 1: Figure 20 As shown, the chuck mechanism and the blocking mechanism are locked and fixed in advance. Specifically, the annular sleeve is placed inside the chuck collar, the chuck hydraulic motor drives the chuck to rotate, and the chuck connecting rod inside the groove rotates. To the outside of the groove, the chuck shaft extends to the outside of the annular tube, the chuck shaft extends into the slot of the chuck collar, the first toothed part and the second tooth of the first clutch part and the second clutch part The disc parts mesh with each other to complete the fixing of the chuck mechanism and the blocking mechanism. The leaking pipeline is located between the opened first and second blocking plates, the jaw clutch hydraulic motor works, the second clutch drives the worm to rotate, the worm drives the worm wheel to rotate, and the worm wheel drives the lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com