Gas flow vector control device

A technology of vector control and gas flow, applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of poor versatility and low adaptability, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

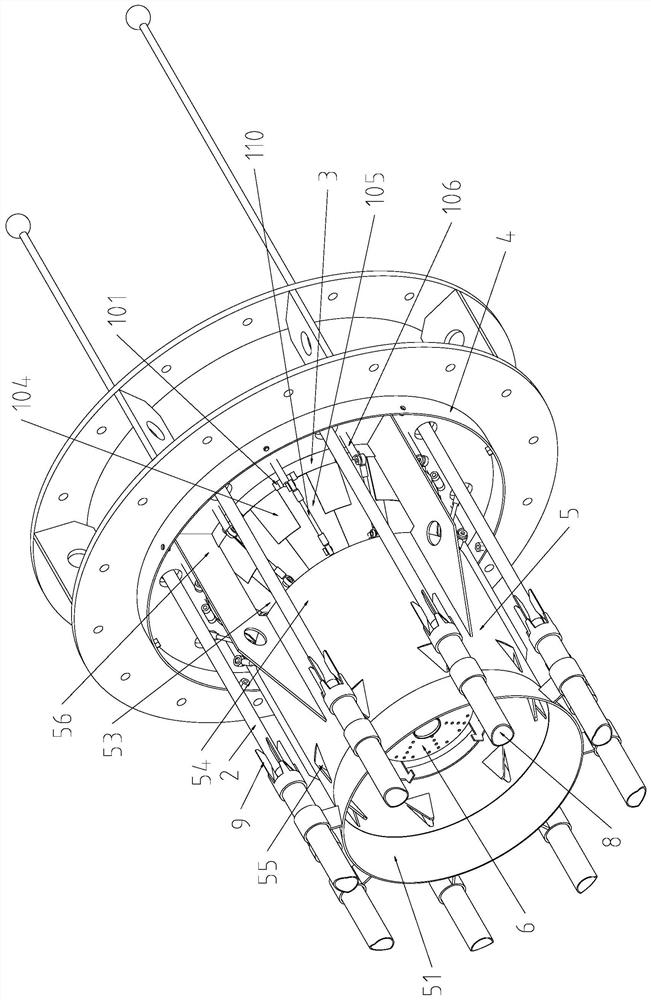

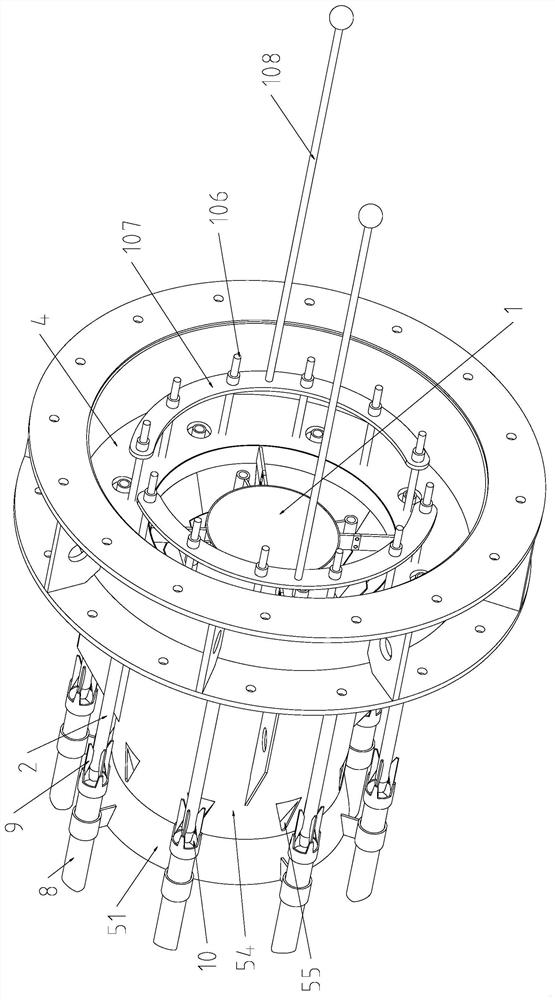

[0029] see figure 1 The vector control gas low-nitrogen burner using the gas flow vector control device shown includes a central air pipe 1, an outer ring air pipe 2, a housing 4 with an air channel (outlet channel) 3 inside, and the inlet of the air channel is connected to the fan (not shown) Draw) the exit is connected.

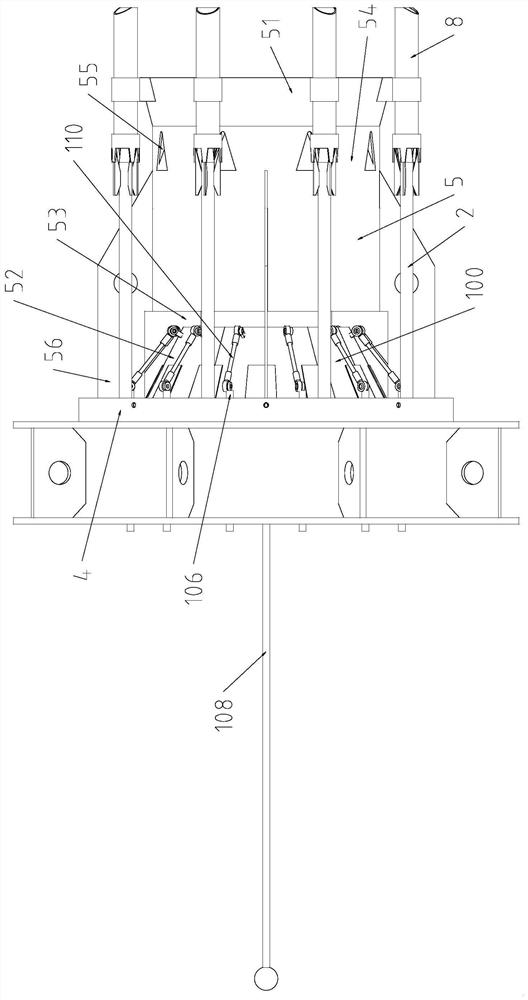

[0030] The air outlet pipe 5 includes a front section air outlet pipe 51, a middle section air outlet pipe 54 and a tapered rear section air outlet pipe 52 with a small front and a large rear, and the front section air outlet pipe 51 is a flared section with a large front and a small rear; The front end of the middle air outlet pipe 54 is docked with the flaring section, and the front end of the rear air outlet pipe 52 has a smaller diameter, forming a smoke gap 53 with the rear end of the middle air outlet pipe with a larger diameter. There are a plurality of smoke inlets 55 on the front side wall of the air outlet pipe 54 in the middle section; The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com