Boiler water-cooled wall temperature distribution rapid detection, analysis and evaluation system

An evaluation system and a water-cooled wall technology, which are applied in the field of rapid detection, analysis and evaluation systems for the temperature distribution of boiler water-cooled walls, can solve the problems of difficult tube numbering and positioning, low labor efficiency in image processing and data collection, and inability to automatically generate numerical analysis reports, etc. To achieve the effect of simple positioning and identification, low cost and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail now in conjunction with accompanying drawing.

[0033] It should be noted that terms such as "upper", "lower", "left", "right", "front", and "rear" quoted in the invention are only for clarity of description, not for Limiting the practicable scope of the present invention, and the change or adjustment of the relative relationship shall also be regarded as the practicable scope of the present invention without substantive changes in the technical content.

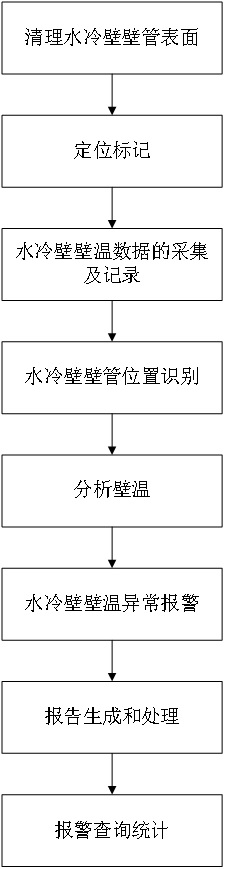

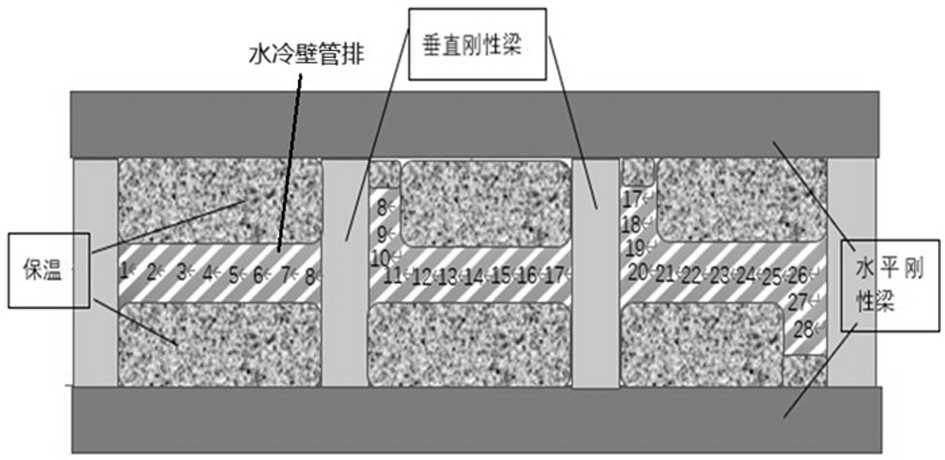

[0034] as attached Figure 1-8 As shown, the present invention provides a rapid detection, analysis and evaluation system for boiler water wall temperature distribution, and the specific implementation steps of an embodiment of the system are as follows:

[0035] S1. Clean the surface of the water-cooled wall pipe: If there is insulation cotton and refractory cement on the surface of the water-cooled pipe, it should be cleaned; if the surface of the pipe is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com