Corner transition smoothing method for smoothing axial jerk

A jerk and corner technology, applied in the field of CNC machining, can solve the problems of single-axis speed, acceleration and jerk mutation, servo drive shaft vibration, and reduce processing quality, so as to reduce processing time, improve efficiency, and improve processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings.

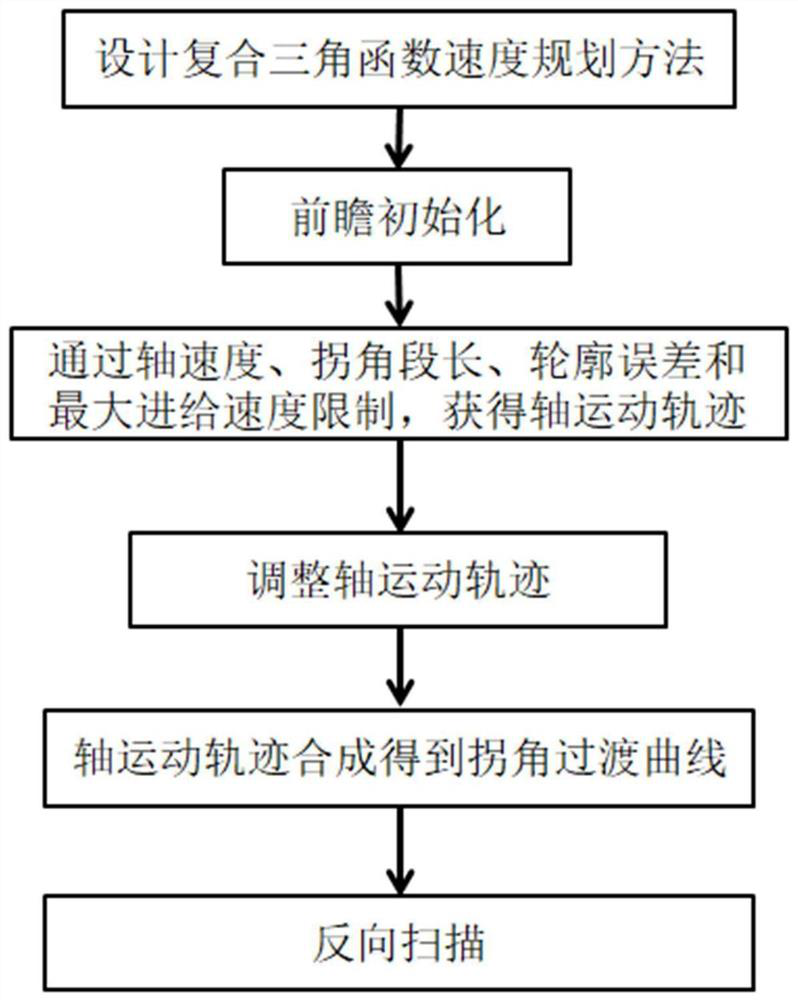

[0057] The invention discloses a corner transition smoothing method for smooth axis jerk, which utilizes a compound trigonometric function speed planning method to simultaneously complete the construction of the corner transition curve and single-axis speed planning within one step, thereby significantly reducing the time required for motion trajectory control. It saves processing time, realizes smooth axis speed, axis acceleration and axis jerk control, and improves the processing quality of CNC machine tools.

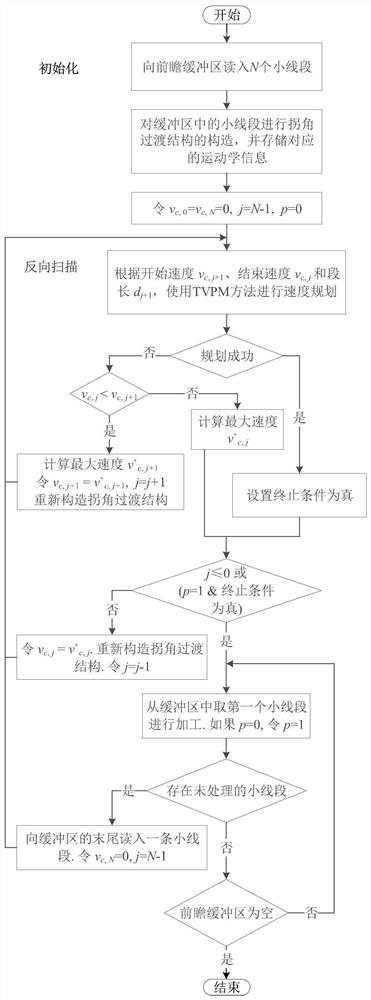

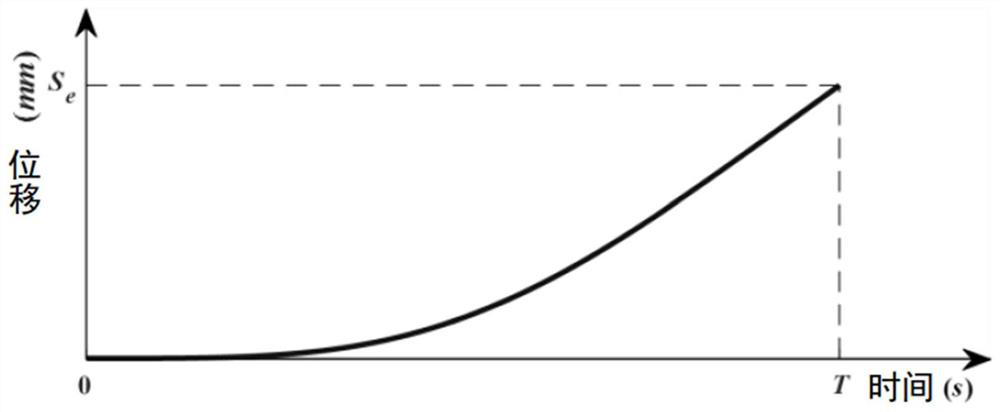

[0058] The invention proposes a corner transition smoothing method with smooth shaft jerk, which solves the processing efficiency and precision problems of complex curves and surfaces. The method consists of forward-looking initialization, compound trigonometric function speed planning method design, symmetrical transition structure construction of corner trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com