Single-column lifting power taking structure and clothes airing machine

A single-column, electric control board technology, applied in the field of parts and components, can solve the problems of no signal device, damaged probe, unsafe exposure of electric shock structure, etc., and achieve the effect of reducing impact force and ensuring heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

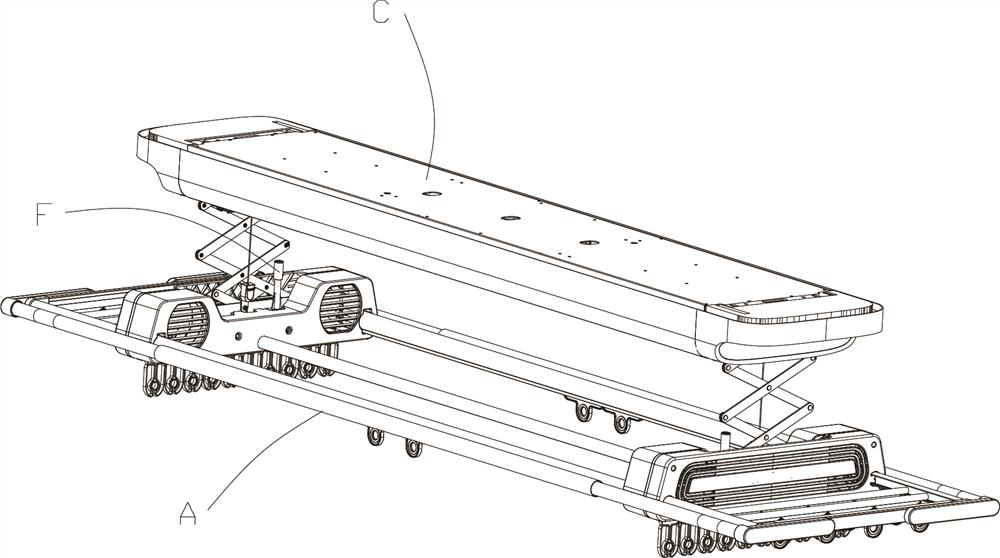

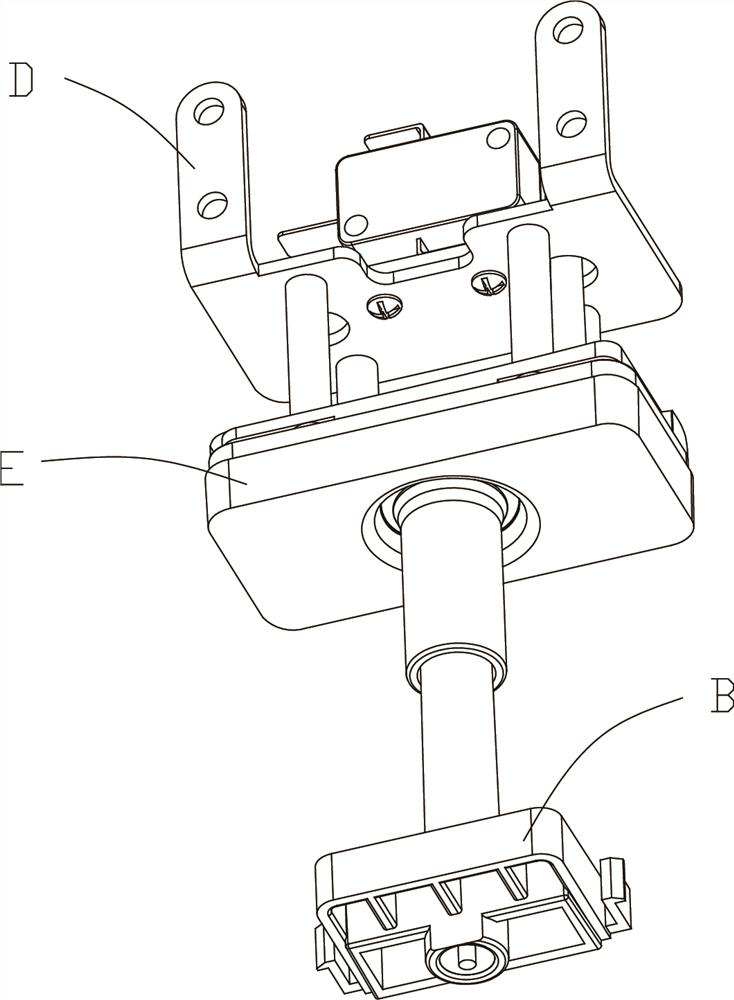

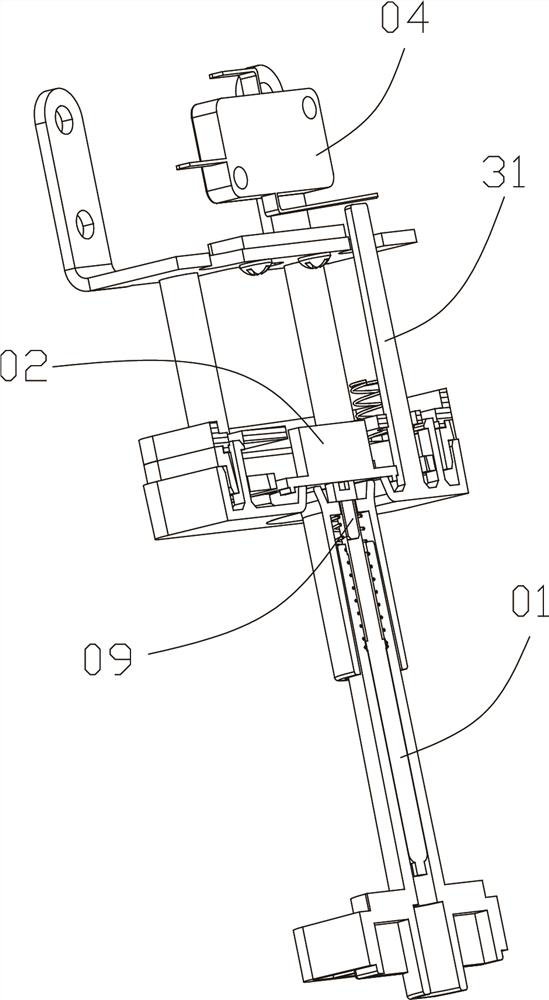

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1-9 As shown, the diagram is marked as follows: Clothes-drying bar A, electric shock component B, clothes-drying main box C, switch component D, connecting component E, single-column lifting power-taking structure F, probe 01, electric control board 02, activity Board 03, signal switch 04, upper sheet metal seat 05, lower sheet metal seat 06, protective cover 07, probe spring 08, copper screw 09, probe seat 10, connecting seat 11, spacer plate 12, return spring 13, Ejector part 31, flat part 32, first electric control board hole 33, inner hook 34, outer hook 35, oblique pin 41, first ejector hole 61, step 011, base plate 111, side seat plate 112, Seat support column 113 , second electric control board hole 114 , second ejector pin hole 115 , second button hole 116 , third electric control board hole 121 , first button hole 122 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com