Submarine cable connection workbench

A workbench and submarine cable technology, applied in the direction of cable installation, cable installation device, dismantling/armouring cable equipment, etc., can solve the problem of no operating platform for submarine cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

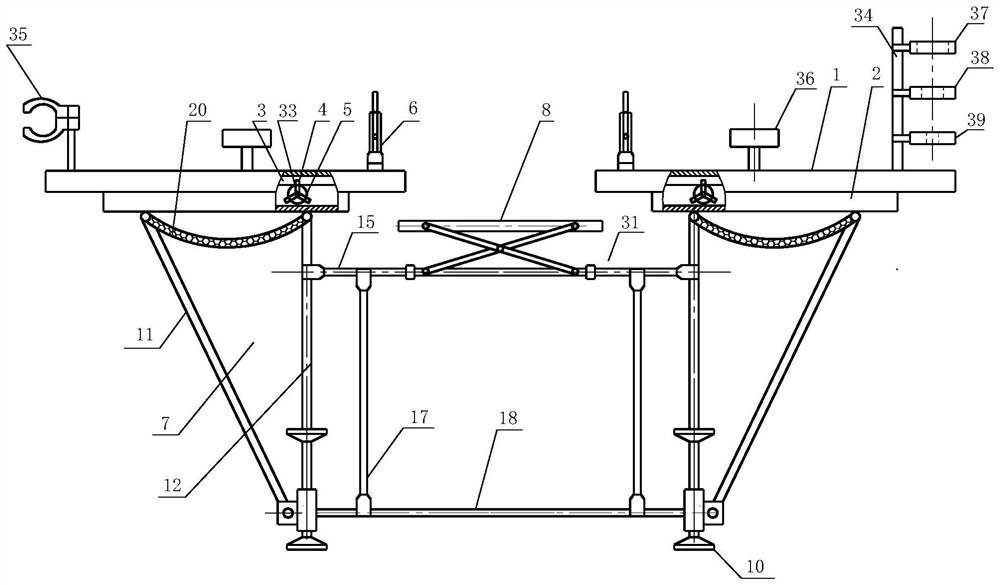

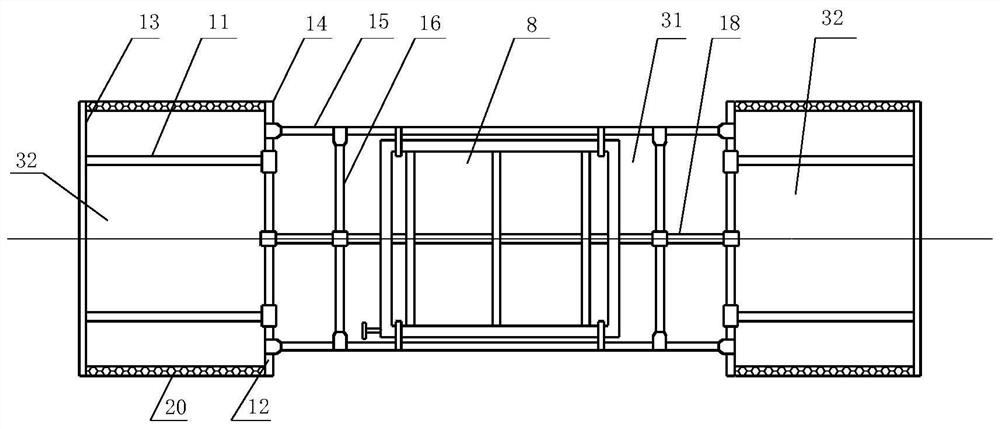

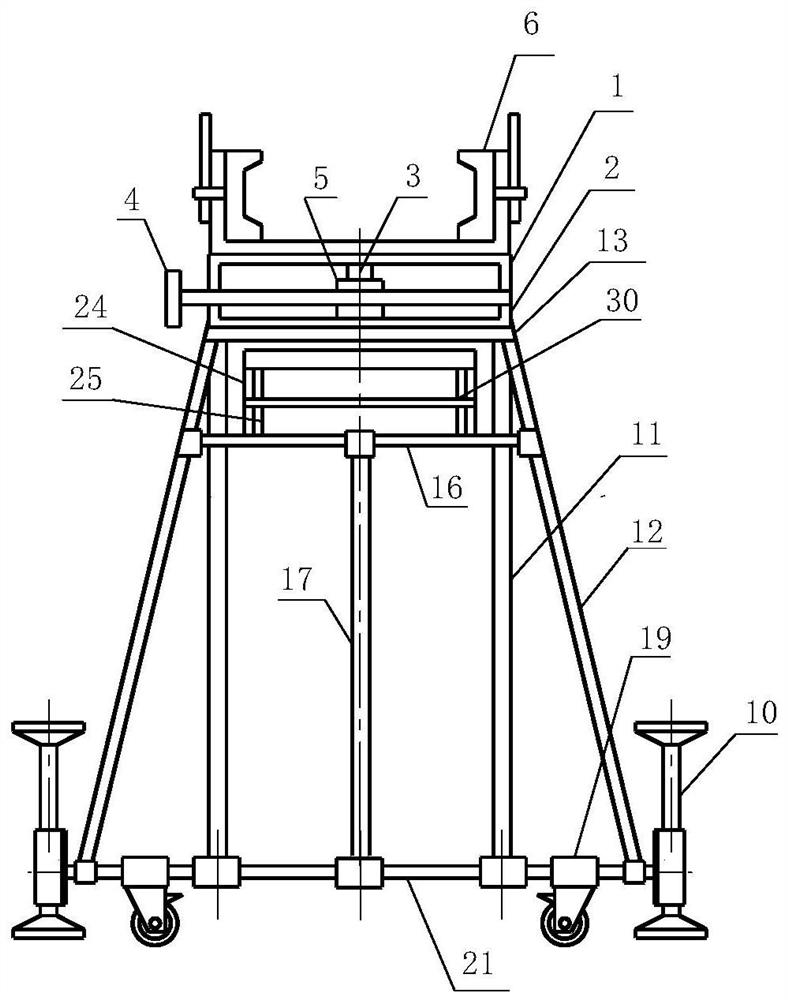

[0024] Such as figure 1 As shown, the submarine cable connection workbench of the present invention includes: an upper mobile platform 1, a lower fixed platform 2, a rack 3, a mobile handle 4, a gear 5, a recessed platform 31, a supporting platform 32, an operating platform 7 and a lifting frame 8, There is a sunken platform 31 in the center of the operating table 7, and a support platform 32 is respectively provided on the left and right sides of the operating table 7, and the lower fixed platform 2 is respectively fixed on the supporting platform 32, and the upper mobile platform 1 is housed on the lower fixed platform 2. The corresponding upper mobile platform 1 and the lower fixed platform 2 form a base, and a rack 3 and a gear 5 are arranged inside each base, and a rack 3 is respectively installed at the lower end of each upper mobile platform 1. A gear 5 is housed inside, the rack 3 meshes with the gear 5, and a connecting shaft 33 is installed in the center of the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com