Method for screening sensory quality characteristic components of tobacco-derived spices

A screening method and tobacco leaf technology, which is applied in the direction of essential oil/spices, tobacco, tobacco preparation, etc., can solve the problems of application results lagging behind research results, poor purpose, applicability and directivity, and failure to find cigarette products, etc., to achieve Good practical significance, excellent sensory quality evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A screening method for the sensory quality characteristic components of tobacco leaf flavors, comprising the steps of:

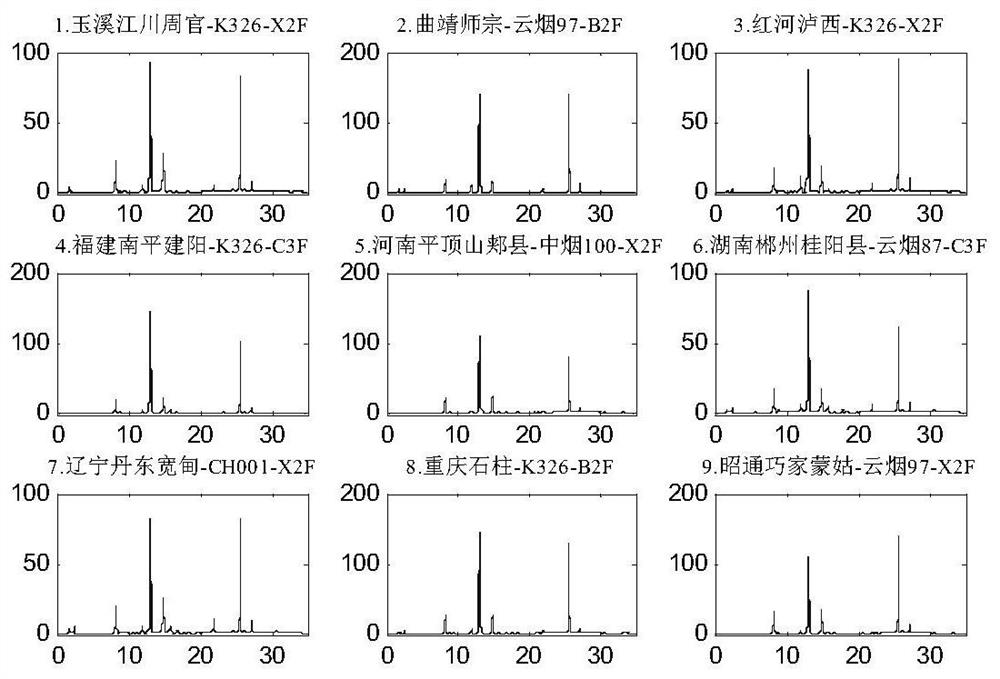

[0044] Step (1), sample collection: collect tobacco leaf samples of different varieties and grades;

[0045] Step (2), sample chromatographic analysis: the tobacco leaf sample collected in step (1) is balanced and pulverized, then shaken and extracted, and the obtained extract is analyzed by high performance liquid chromatography;

[0046] Step (3), sample sensory evaluation: sensory evaluation of the quality characteristics of the tobacco leaf sample collected in step (1); the sensory quality characteristics include aroma quantity, aroma quality, irritation, and miscellaneous odor;

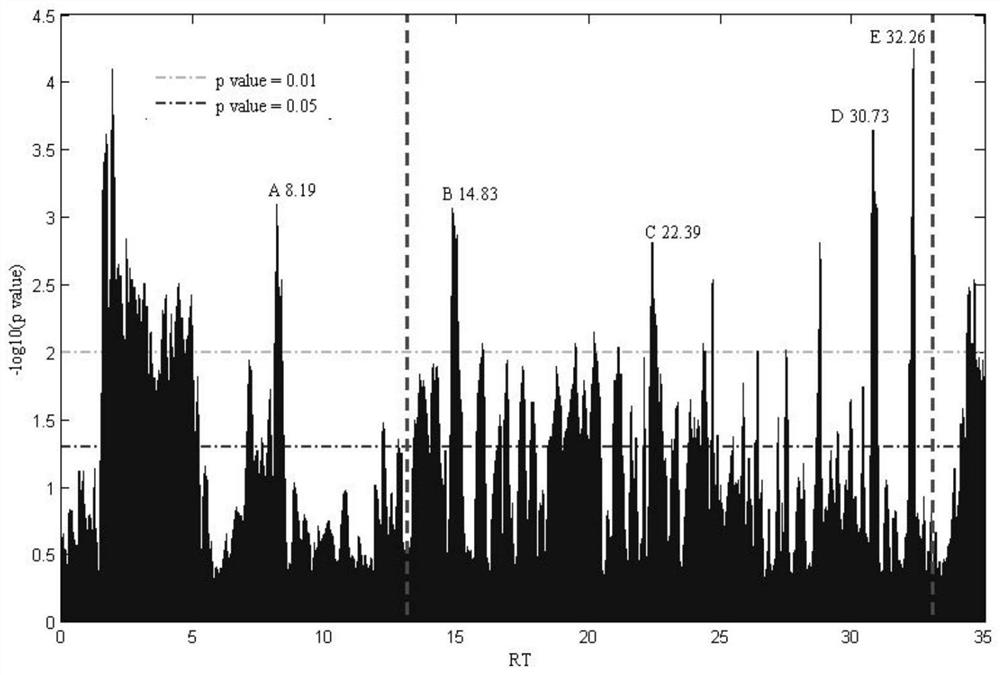

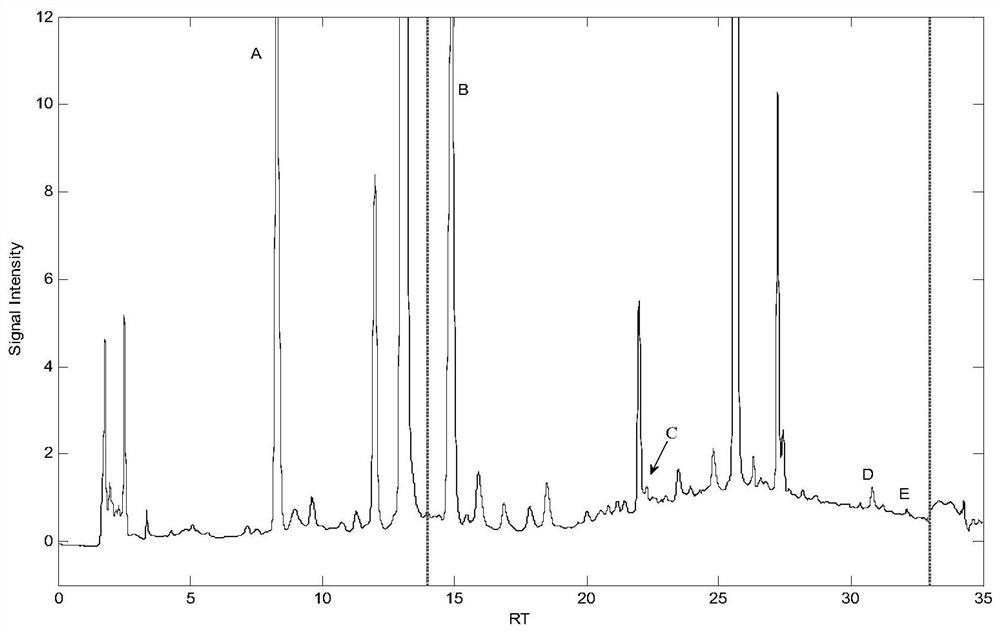

[0047] Step (4), preprocessing: export the raw data of the liquid chromatogram of tobacco leaves analyzed in step (2), perform baseline correction and peak alignment, and obtain the sample numbers as columns, retention time as rows, and each data point as The liquid pha...

Embodiment 2

[0054] A screening method for the sensory quality characteristic components of tobacco leaf flavors, comprising the steps of:

[0055] Step (1), sample collection: collect tobacco leaf samples of different varieties and grades;

[0056] Step (2), sample chromatographic analysis: the tobacco leaf sample collected in step (1) is balanced and pulverized, then shaken and extracted, and the obtained extract is analyzed by high performance liquid chromatography;

[0057] Step (3), sensory evaluation of samples: according to YC∕T 530-2015 "Sensory Evaluation Method for Quality and Style Characteristics of Flue-cured Tobacco Leaf", perform sensory evaluation on the quality characteristics of the tobacco leaf samples collected in step (1); the sensory quality characteristics include Aroma quantity, aroma quality, irritating, miscellaneous;

[0058] Step (4), preprocessing: export the raw data of the liquid chromatogram of tobacco leaves analyzed in step (2), perform baseline correctio...

Embodiment 3

[0070] A screening method for the sensory quality characteristic components of tobacco leaf flavors, comprising the steps of:

[0071] Step (1), sample collection: collect tobacco leaf samples of different varieties and grades;

[0072] Step (2), sample chromatographic analysis: the tobacco leaf sample collected in step (1) is balanced and pulverized, then shaken and extracted, and the obtained extract is analyzed by high performance liquid chromatography;

[0073] Step (3), sample sensory evaluation: sensory evaluation of the quality characteristics of the tobacco leaf sample collected in step (1); the sensory quality characteristics include aroma quantity, aroma quality, irritation, and miscellaneous odor;

[0074] Step (4), preprocessing: export the raw data of the liquid chromatogram of tobacco leaves analyzed in step (2), perform baseline correction and peak alignment, and obtain the sample numbers as columns, retention time as rows, and each data point as The liquid pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com