A method and system for identifying risk of disc shearing and edge blocking in a cold rolling production line

A risk identification, disc shearing technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problem of disc shearing edge plugging failure without effective pre-control means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

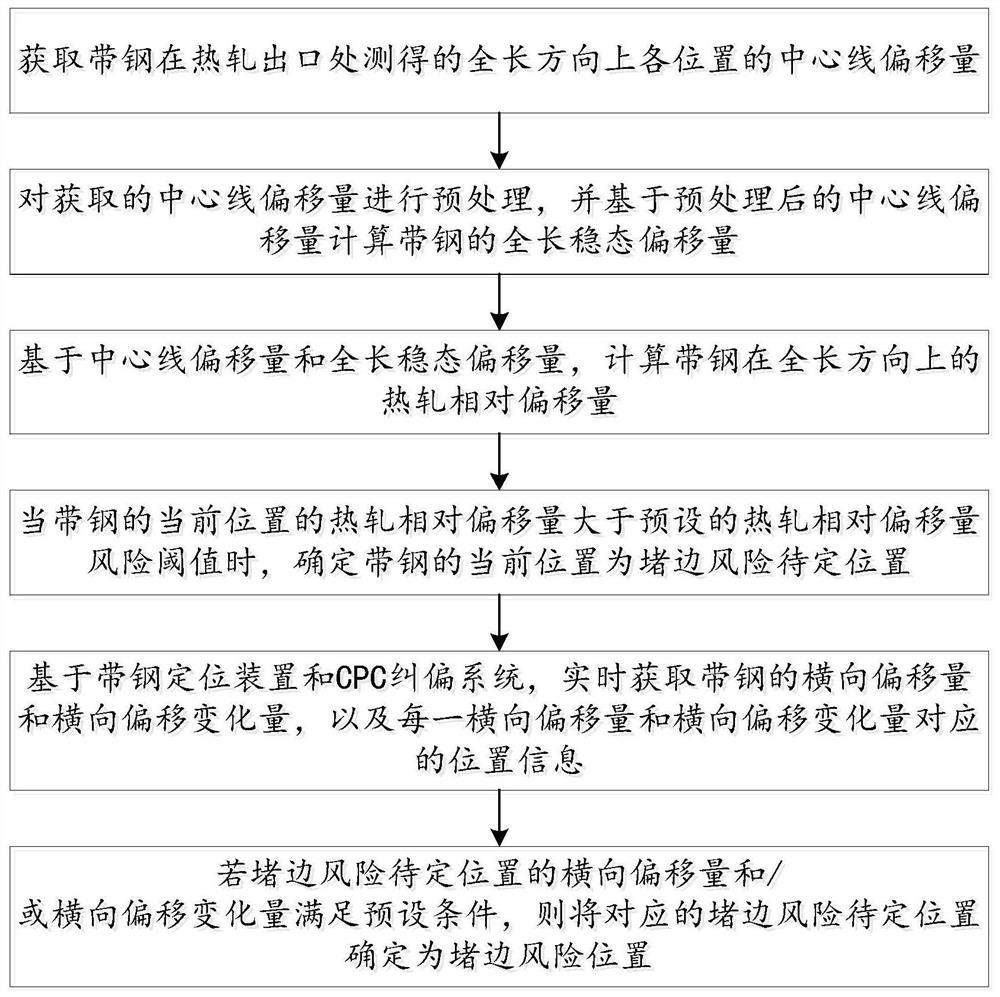

[0074] This embodiment provides a method for identifying the risk of side disc shearing and blocking in a cold rolling production line. Decisions are made by acquiring hot rolling data and cold rolling real-time data, combining the influence of hot rolling quality problems genetics and the operation of strip steel at the entrance section of cold continuous rolling In the hot rolling process, carry out risk pre-identification on parts with a high risk of edge blocking, such as camber bends caused by difficult rolling control of the head and tail parts of the strip in the hot rolling process, and strip width loss during the rolling process. Combining the risk of edge blocking caused by material characteristics and the risk of edge blocking caused by operating conditions for risk identification can provide early warning of production for edge blocking problems; this method can be realized by electronic equipment, which can be a terminal or a server.

[0075] Among them, if the ris...

no. 2 example

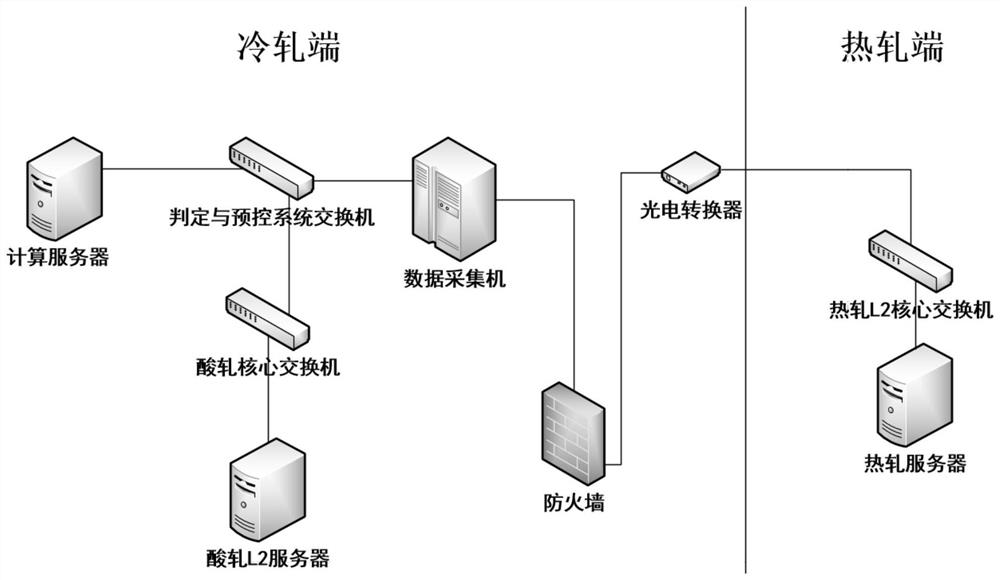

[0148] This embodiment provides a risk identification system for disc shearing edge blocking in a cold rolling production line. The cold rolling production line is equipped with a strip positioning device, a CPC deviation correction system and disc shearing equipment. The system includes: based on the hot rolling incoming material data The edge blocking risk identification module and the edge blocking risk identification module based on cold rolling deviation monitoring data; among them,

[0149] The blockage risk identification module based on hot rolling incoming material data is used for:

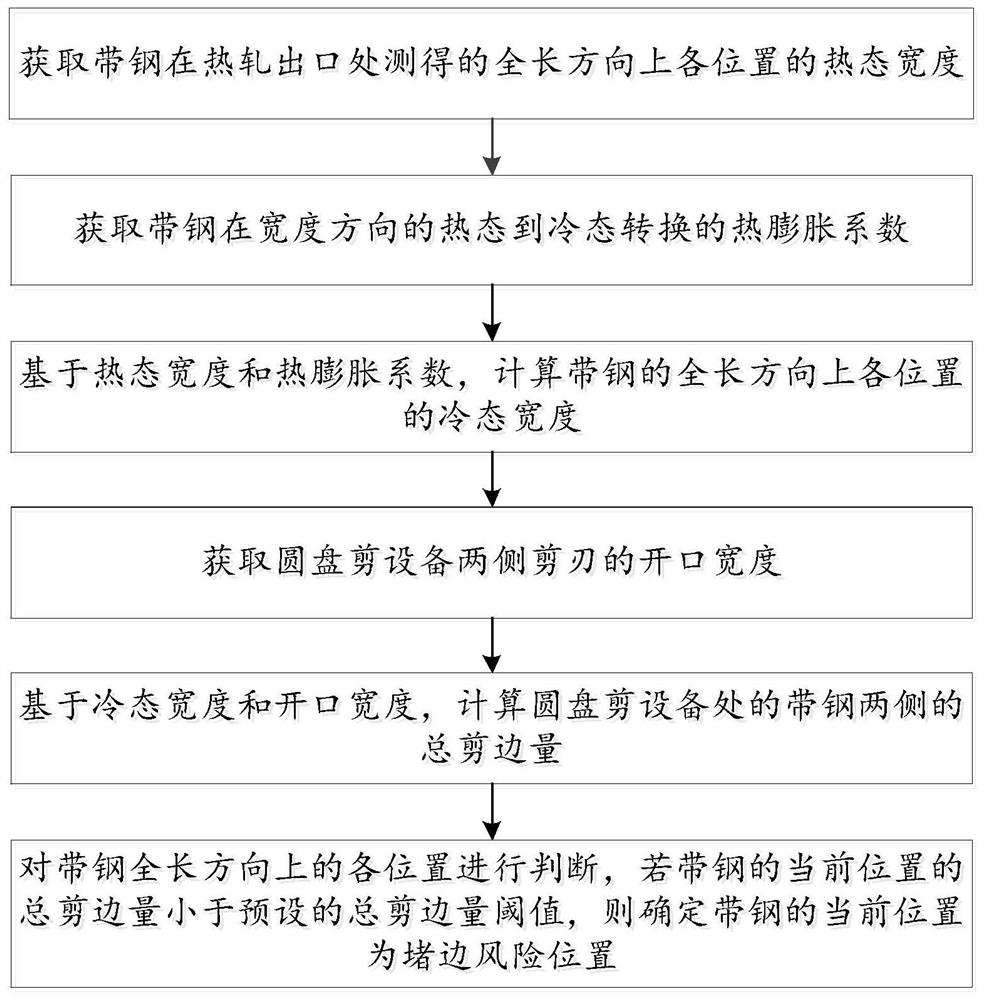

[0150] Based on the hot-state width of each position in the full length direction measured at the exit of the hot-rolled steel strip that is about to be launched at present and the opening width of the cutting blades on both sides of the disc shearing equipment, the total shear on both sides of the strip is calculated. margin;

[0151] Judging each position in the full length direction ...

no. 3 example

[0159] This embodiment provides an electronic device, which includes a processor and a memory; at least one instruction is stored in the memory, and the instruction is loaded and executed by the processor, so as to implement the method of the first embodiment.

[0160] The electronic device may have relatively large differences due to different configurations or performances, and may include one or more processors (central processing units, CPU) and one or more memories, wherein at least one instruction is stored in the memory, so The above instructions are loaded by the processor and realize edge blocking risk identification based on hot rolling incoming material data and edge blocking risk identification based on cold rolling deviation monitoring data; wherein,

[0161] Edge blocking risk identification based on hot rolling incoming material data, including:

[0162] Based on the hot-state width of each position in the full-length direction measured at the exit of the hot-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com