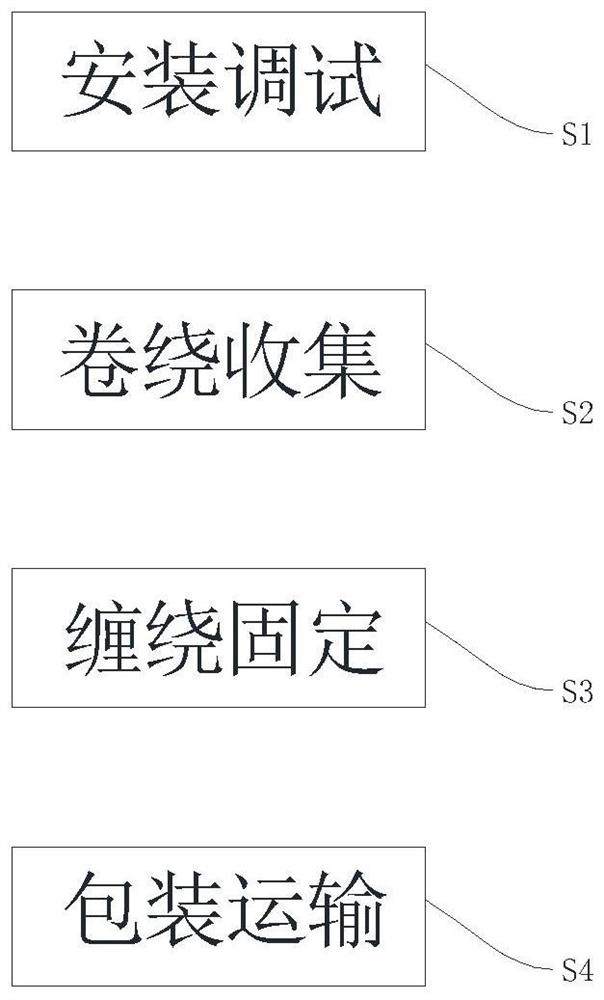

Geotextile production process

A production process and technology of geotextiles, applied in the direction of winding strips, packaging, and strapping machine parts, etc., can solve problems such as difficult reuse, cumbersome operation, and loss of geotextiles, so as to improve work efficiency and improve winding Quantity, the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

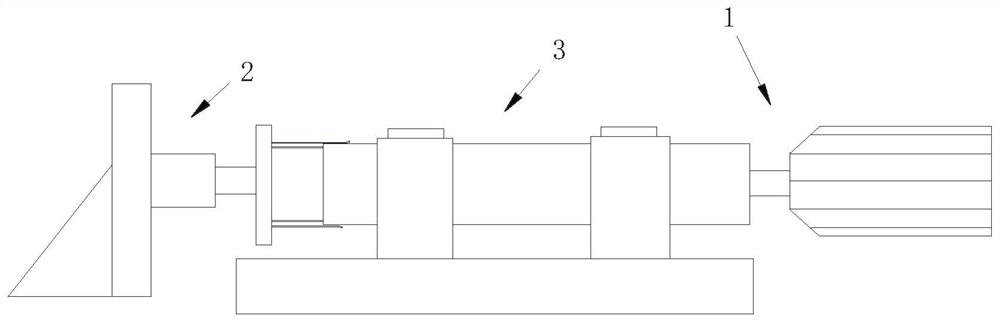

[0038] refer to figure 2As shown, it is a geotextile production process disclosed in the present invention, which uses a geotextile production equipment, which is mainly used in the winding operation of the geotextile, which is convenient for the operator to operate and improves the winding efficiency. Among them, the equipment includes winding device 1, fixing part 2 and fixing device 3; fixing part 2 fixes the geotextile on the winding device 1, winding device 1 winds and fixes the geotextile, and fixing device 3 winds the geotextile The finished geotextile is fixed to prevent the geotextile from unraveling.

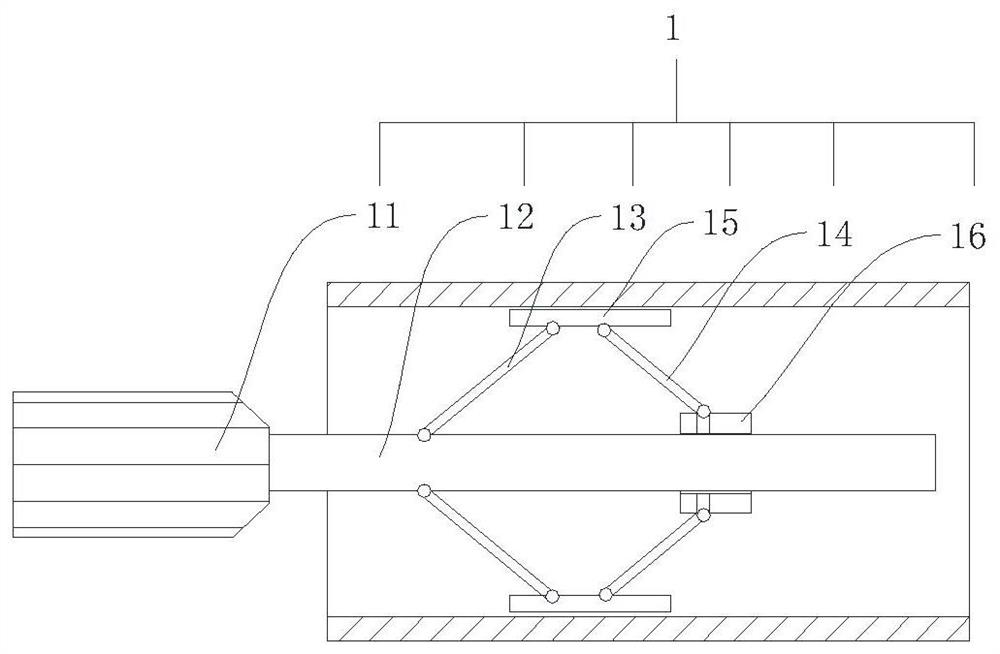

[0039] refer to image 3 As shown, the winding device 1 includes a drive motor 11, an extension rod 12, a first support rod 13, a second support rod 14, a support block 15 and a threaded sleeve 16; in this embodiment, the output of the extension ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com