Lifting frame for bored pile in limited space

A technology of limited space and bored piles, which is applied in the direction of cranes, cranes, load hanging components, etc. of trolleys, can solve the problems of inability to use pile foundation construction, narrow construction space, and heavy frame weight, etc., to achieve small construction space, The effect of ensuring work safety and high overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

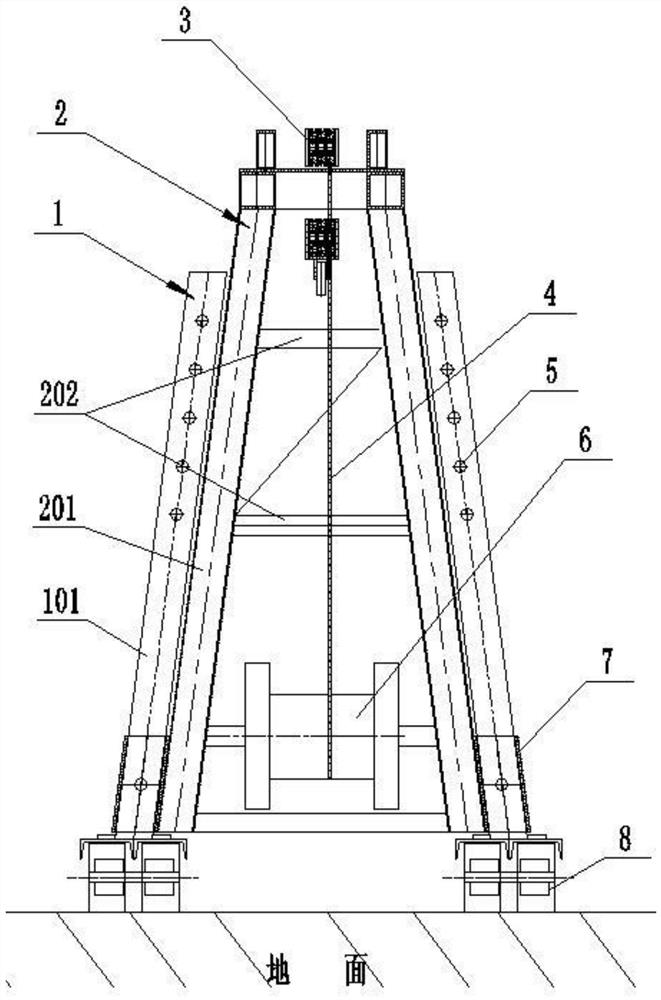

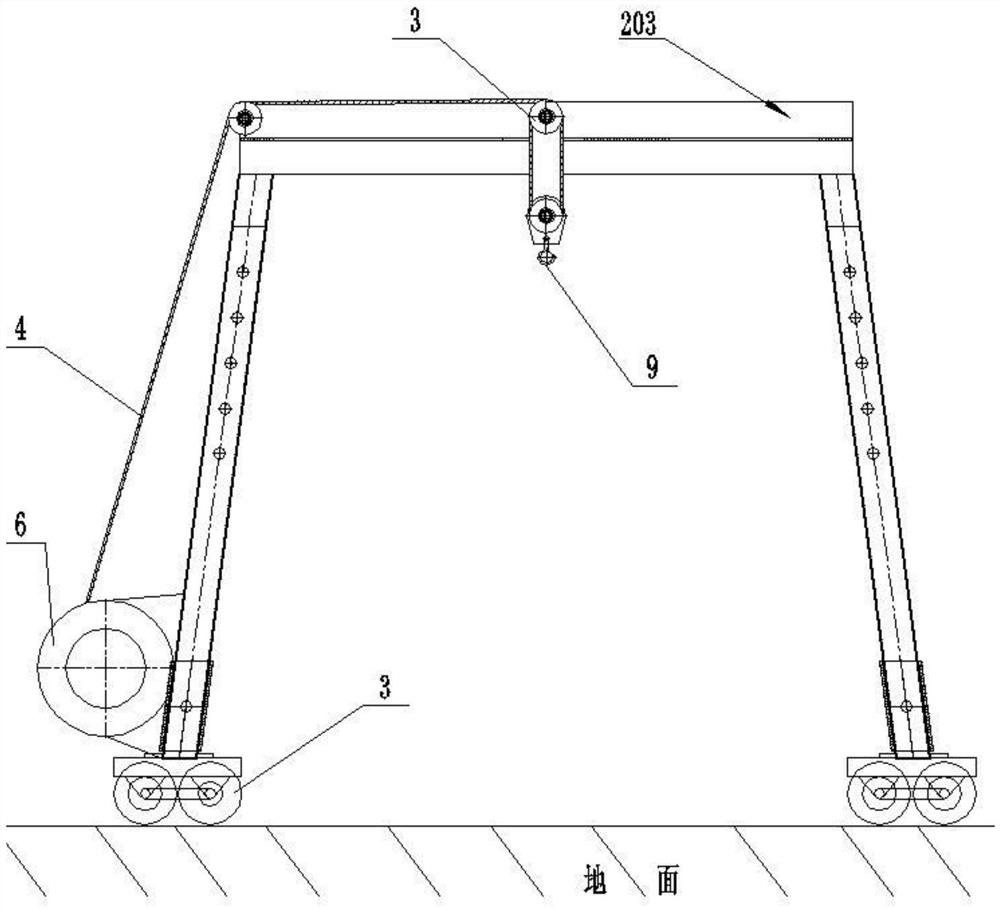

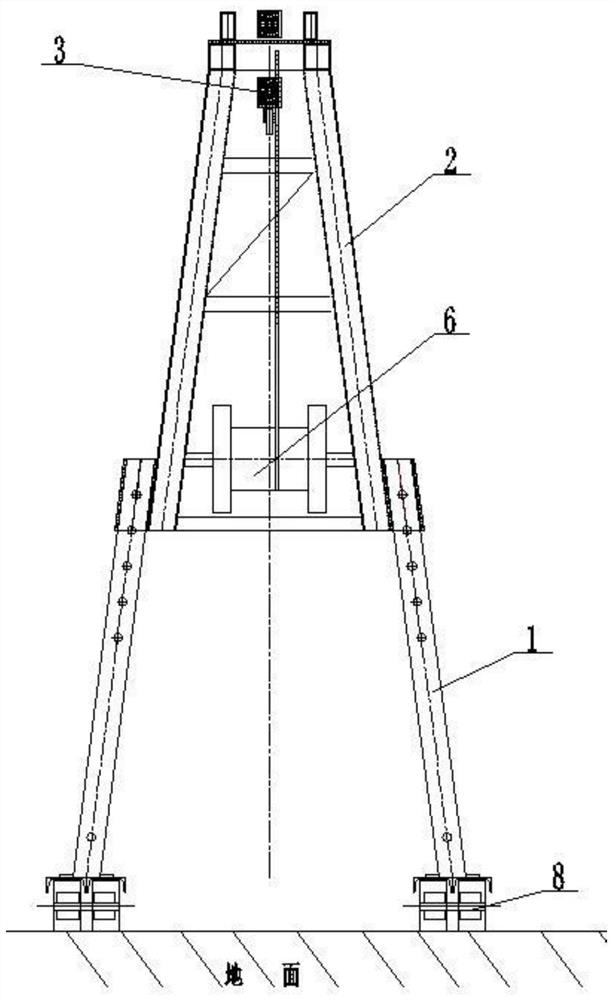

[0017] As shown in the drawings, a lifting frame used for bored piles in a limited space includes a fixed frame 1 and a movable frame 2 . The fixed frame 1 includes four vertical steel frames I101 arranged in a rectangular shape. The lower end of each steel frame I101 is connected with a group of moving wheels 8, and the moving wheels 8 and the lower ends of the steel frame I101 are connected by channel steel welding. The movable frame 2 is composed of four vertically arranged steel frames II201 arranged in a rectangular shape, a connecting brace 202 connected between the four steel frames II201 and a beam 203 connected to the upper ends of the four steel frames II201. The steel frame II201 It is connected with the connecting brace 202 and the beam 203 by welding, and a casing 7 is fixedly connected to the outside of the lower end of each steel fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap