Fabricated rock anchor rod composite foundation and construction method thereof

A technology of rock bolts and composite foundations, applied in the field of transmission tower foundations, can solve problems such as large influence of natural factors, low construction efficiency, long foundation production cycle, etc., meet environmental protection requirements, increase construction speed, and simple construction methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

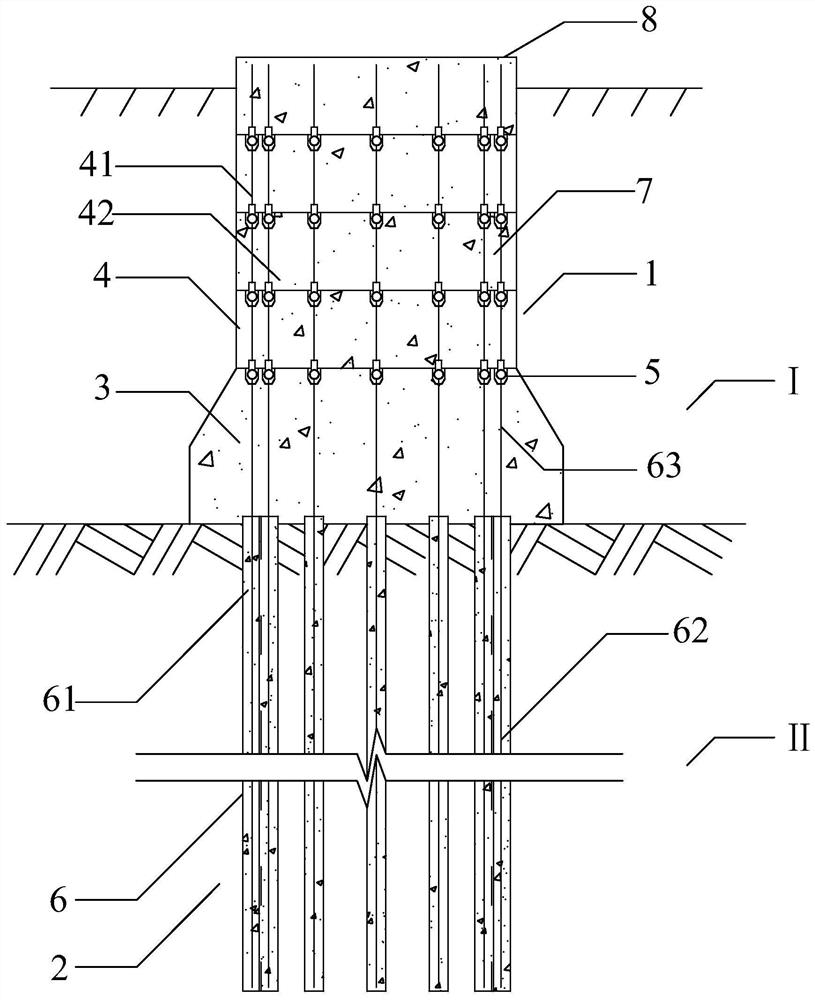

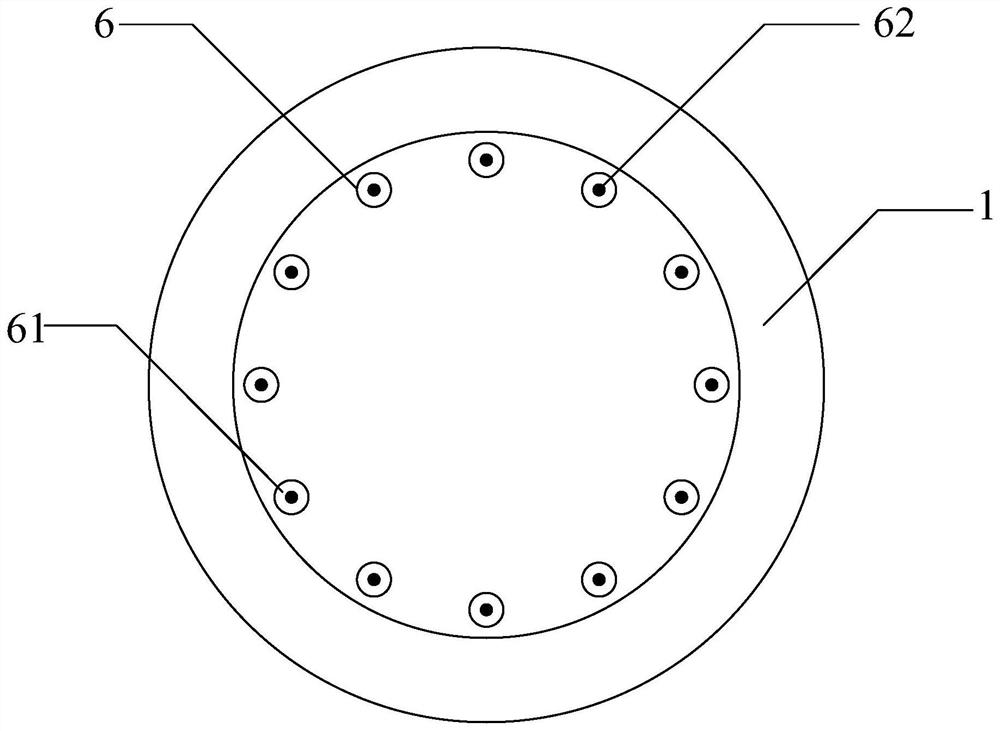

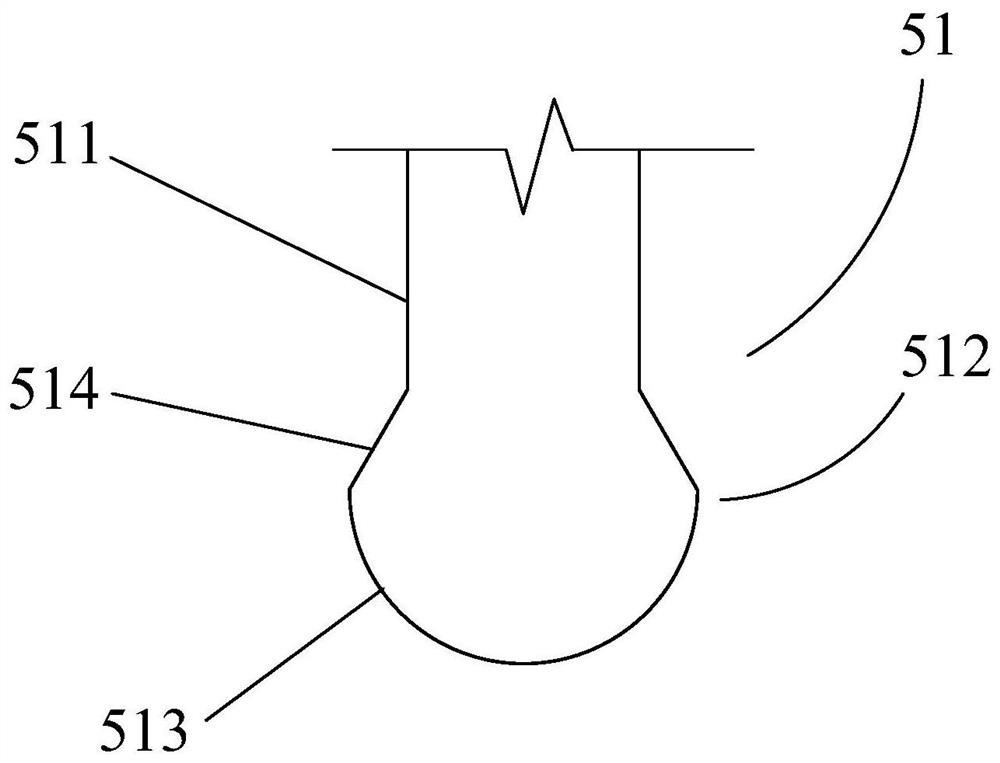

[0044] Embodiment 1: as Figure 1-2 As shown, a prefabricated rock-bolt composite foundation includes a prefabricated pottery foundation 1 and a bolt foundation 2, the prefabricated pottery foundation 1 is located in soil layer I, and the prefabricated pottery foundation 1 includes the existing Pouring, excavating, excavating, and expanding the bottom section 3 and several excavated pottery foundation concrete blocks 4, the excavated pottery foundation concrete block 4 has a height of 200-1000 mm in the vertical direction, including a prefabricated foundation segment 7 and a top floor prefabricated foundation segment 8. The excavated pottery foundation concrete block 4 is composed of the main reinforcement 41 of the assembled foundation section and the excavated pottery foundation concrete 42, and the excavation is carried out between the cast-in-place excavation base expansion section 3 and the excavation base concrete block 4 The basic mechanical connection device 5 is conne...

Embodiment 2

[0058] Embodiment 2: as Figure 8 As shown, the difference from Embodiment 1 lies in that the cross-sectional shape of the prefabricated excavated pottery foundation 1 in the vertical direction is rectangular.

Embodiment 3

[0059] Embodiment 3: as Figure 9 As shown, the difference from Embodiment 1 is that the cross-sectional shape of the prefabricated excavated pottery foundation 1 in the vertical direction is an inverted funnel shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com