Friction clutch for electric drive machine having axis of rotation

A technology of friction clutch and electric drive machine, applied in the direction of friction clutch, mechanical drive clutch, clutch, etc., can solve the problem of limited radial installation space, etc., and achieve the effect of less leftover material share and simple assemblability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

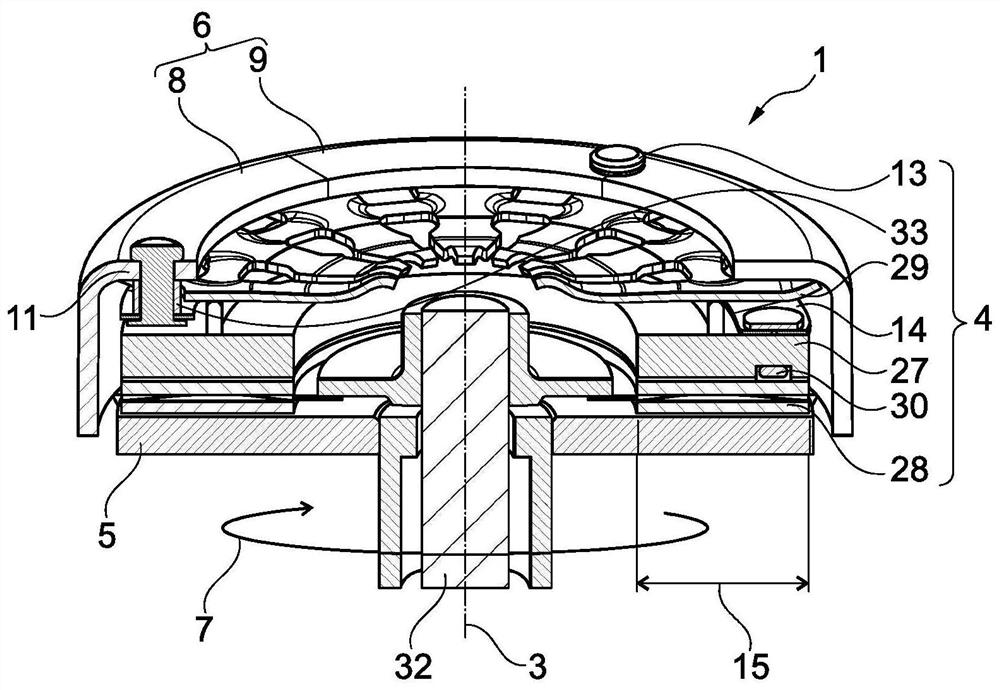

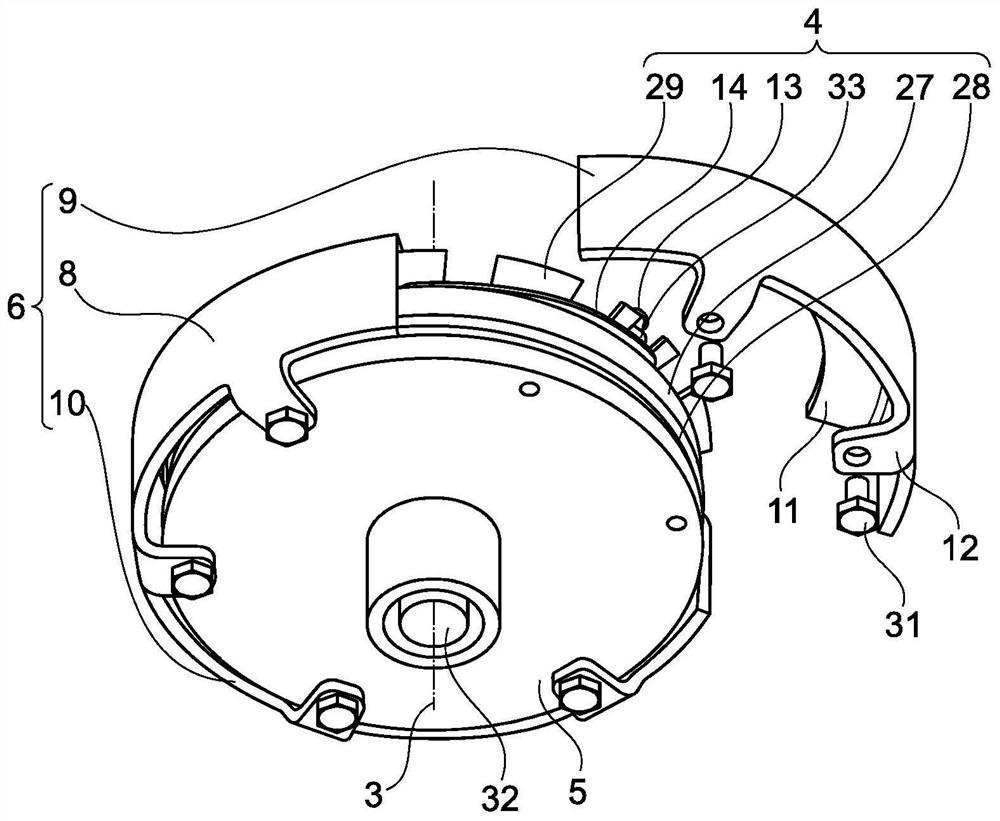

[0048] exist figure 1 The friction clutch 1 is shown in perspective section in the figure 2 Shown in perspective view. The components of the friction clutch 1 are rotatable about a central axis of rotation 3 . As in a conventional friction clutch 1 , when the friction pack 4 is not compressed, the friction disc 28 together with the central shaft, for example the transmission input shaft 32 , can move relative to the clutch cover 6 , the counter plate 5 and the remaining parts of the friction pack 4 . rotate. The friction group 4 here comprises the pressure plate 27 and the friction disk 28 as a friction pair. The friction disk 28 shown here has, in conventional manner, a friction lining on each side and (optionally) a lining spring arrangement in between. For actuation, the friction group 4 (optionally) comprises a lever spring 29, which is supported on the pressure plate 27 (here via the cam ring) and oppositely supported radially as far as possible on the outside at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com