A true triaxial test device for ultra-deep drilling cores capable of simulating deep geological environments

A geological environment and test device technology, applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as test failure, uneven force, loading eccentricity, etc., and achieve a small loss of frame stiffness , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

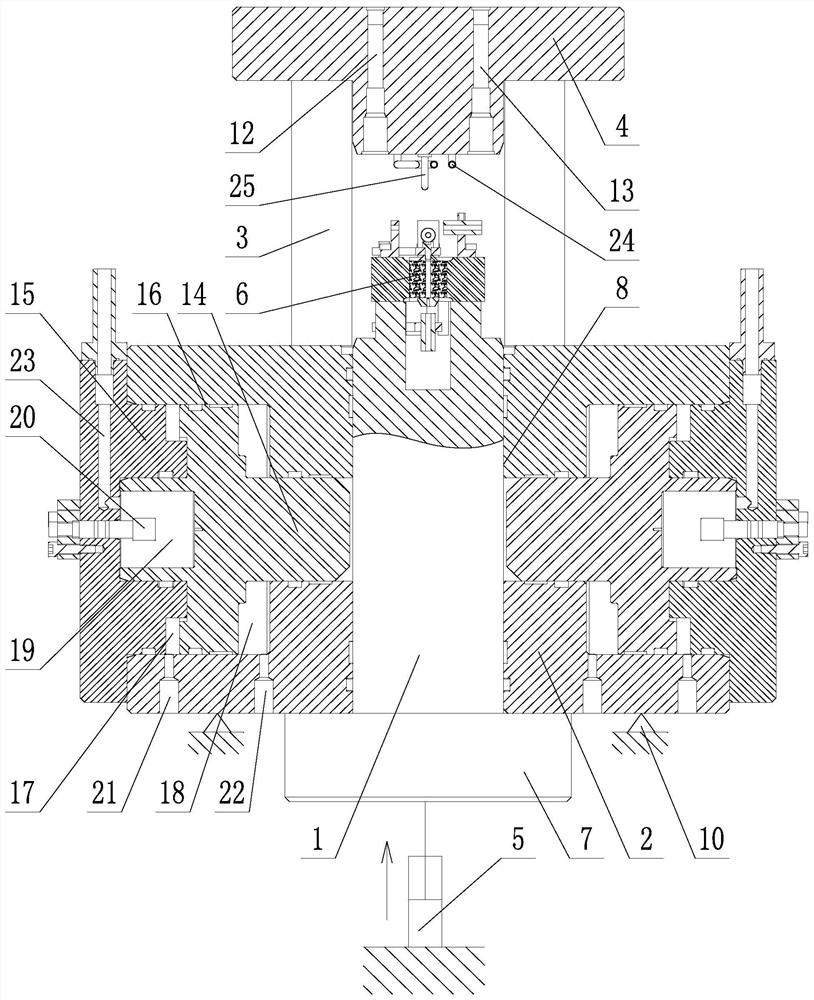

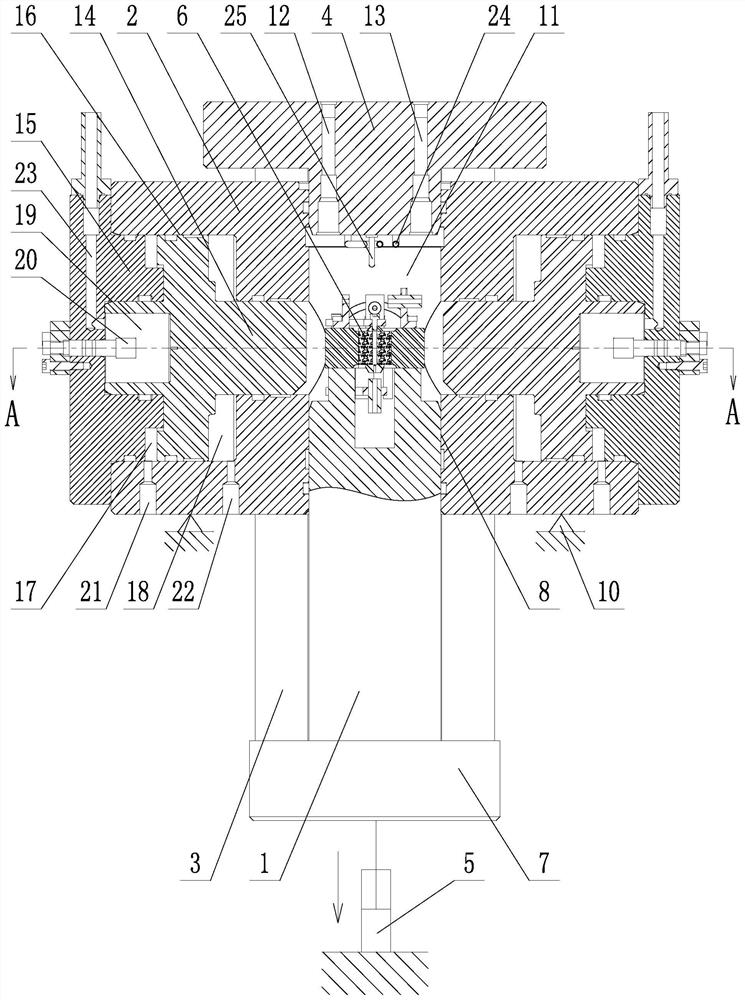

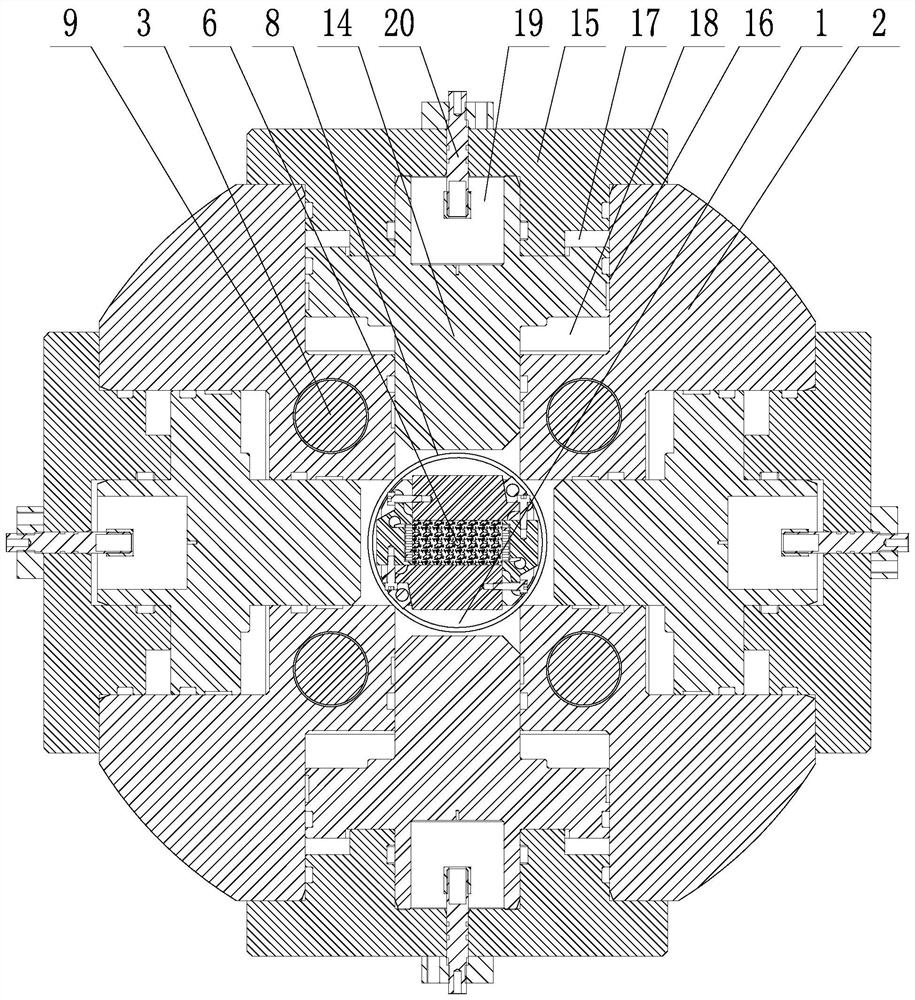

[0019] like Figure 1~3 As shown, a true triaxial test device for ultra-deep drilling cores capable of simulating the deep geological environment, including a rock sample support frame 1, a composite loading frame 2, a guide column 3, a confining pressure sealing cover 4 and a jacking mechanism 5; the rock sample support frame 1 adopts a cylindrical structure, the rock sample support frame 1 is vertically arranged and the top is used to place the rock sample 6, and the bottom of the rock sample support frame 1 is provided with a disc support base 7; The confining pressure sealing cover plate 4 adopts a two-stage stepped cylindrical platform structure, the small diameter end of the confining pressure sealing cover plate 4 is set downward, and the small diameter end of the confining pressure sealing cover plate 4 is equal to the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com