Sampling system for engineering supervision

A sampling system and supervision technology, applied in the direction of sampling devices, etc., can solve the problems of heavy workload of sampling personnel, complicated sampling work, and reduced sampling efficiency, so as to reduce the probability of outflow, reduce waste, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 1-7 will be described in further detail below in conjunction with the accompanying drawings.

[0047] The embodiment of the application discloses a sampling system for engineering supervision.

[0048] In this embodiment, the temperature controller model is TC4S / H / M / L.

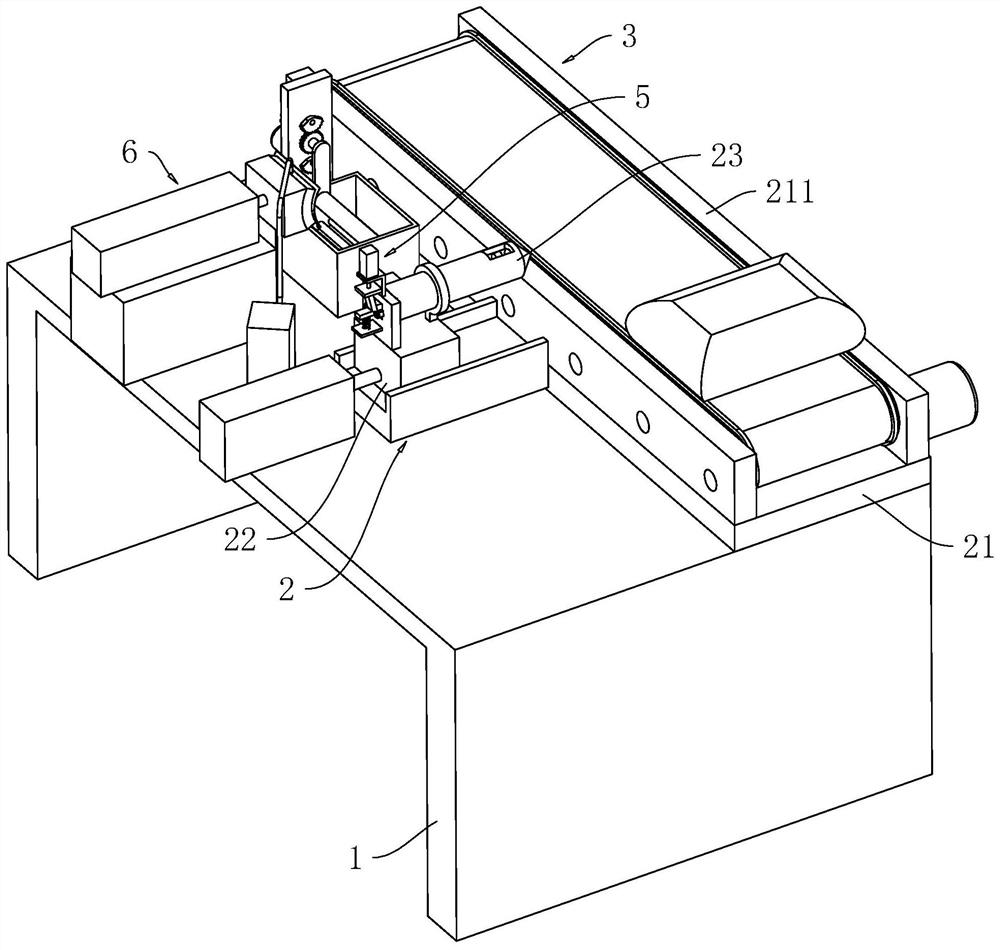

[0049] refer to figure 1 , The sampling system for engineering supervision includes a frame 1, and a sampling mechanism 2 is arranged on the upper surface of the frame 1.

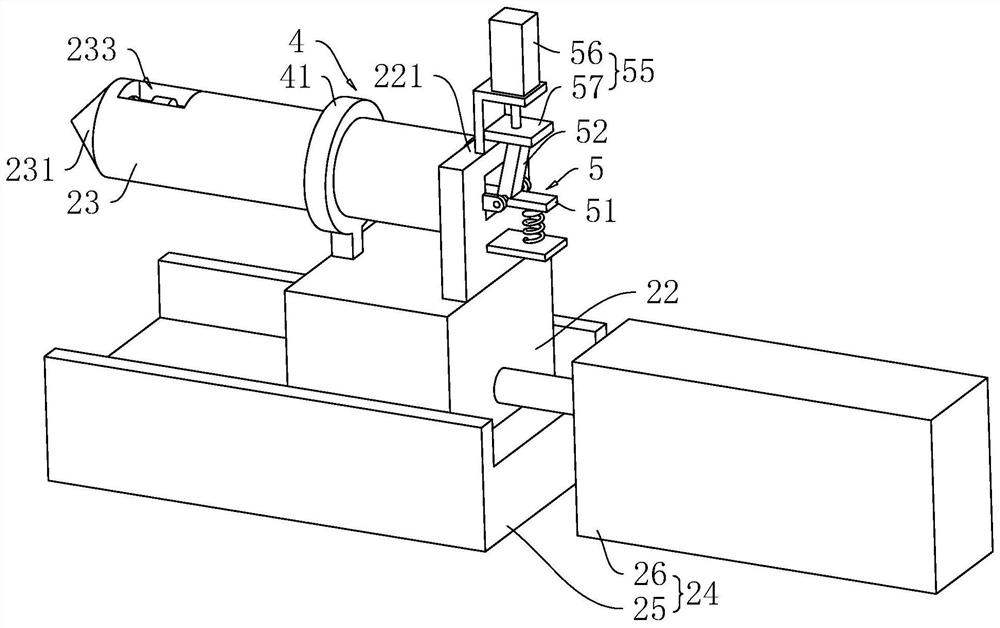

[0050] refer to figure 1 and figure 2 , The sampling mechanism 2 includes a mounting table 21 , a sliding table 22 , a sampling cylinder 23 , and a driving device 24 ; the mounting table 21 is fixedly installed on the upper surface of the frame 1 .

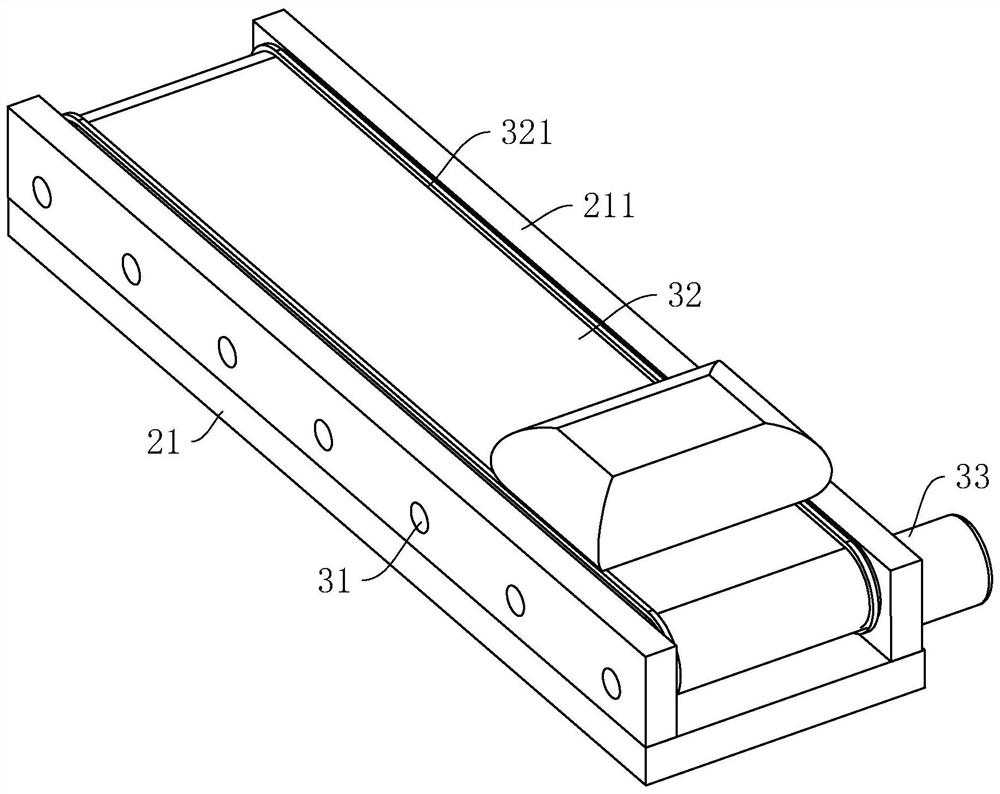

[0051] refer to figure 1 and image 3 , the mounting table 21 is provided with a conveying mechanism 3, the conveying mechanism 3 includes a conveying roller 31, a conveyor belt 32, and a conveying motor 33, and two rectangular conveying plates 211 are fixedly installed on the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com