Manufacturing method of lead-acid storage battery

A technology for lead-acid batteries and manufacturing methods, which is applied in the direction of lead-acid batteries, lead-acid battery construction, and final product manufacturing. It can solve the problems of unsealable and independent storage of acid, and cannot be separated, so as to achieve accurate acquisition and flexible production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

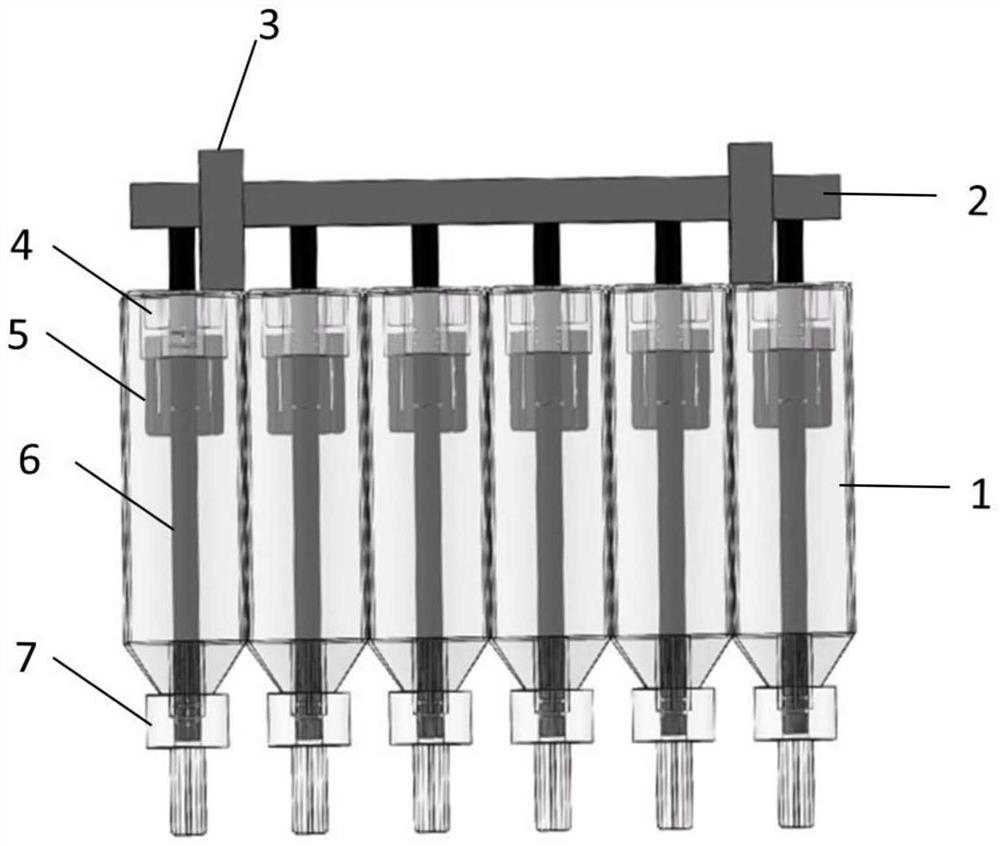

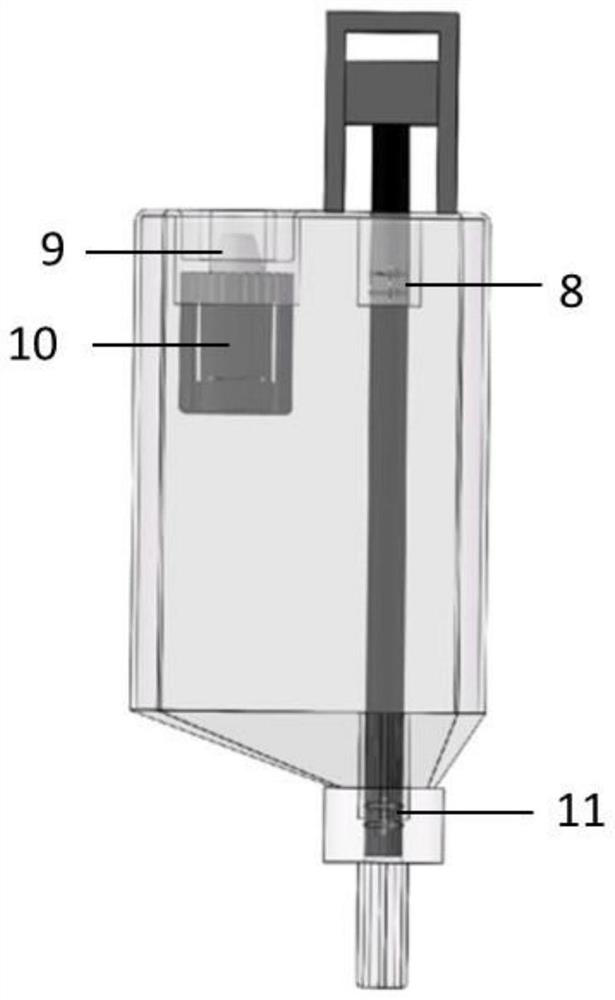

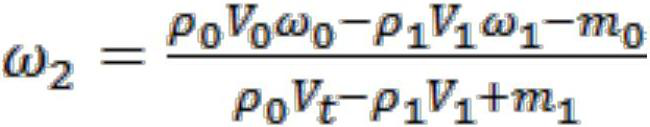

Method used

Image

Examples

Embodiment 1

[0024] Take 6-DZF-20 glue-sealed battery semi-finished products, and use the method of the present invention to add acid and chemically form. The sample preparation process is as follows:

[0025] 1) Add acid for the first time, add sulfuric acid solution with the first density of 1.07g / cm3 to the lead-acid battery to be added, the volume of acid addition is 140ml, and acid can be added in multiple times, the first time is 60ml, and the latter time is 80ml. Add acid by vacuum acid adding machine.

[0026] 2) Place the battery that has been acidified for the first time in a water bath, connect the charging cable clamp, turn on the charger, and proceed according to the process in Table 1.

[0027] Table 1 6-DZF-20 manufacturing process

[0028] step Way Current (A) time (h) Power (Ah) 1 Charge 0.4 0.5 0.2 2 Charge 0.8 0.5 0.4 3 Charge 1.6 0.5 0.8 4 Charge 3 0.5 1.5 5 Charge 3.5 0.875 3.0625 6 Charge 4 14 56...

Embodiment 2

[0042] Take 6-DZF-20 glue-sealed battery semi-finished products, and use the method of the present invention to add acid and chemically form. The sample preparation process is as follows:

[0043] 1) Add acid for the first time, add sulfuric acid solution with the first density of 1.17g / cm3 to the lead-acid battery to be acidified, the volume of acid added is 145ml, and acid can be added in multiple times, the first time is 60ml, and the latter time is 85ml. Add acid by vacuum acid adding machine.

[0044] 2) Place the battery that has been acidified for the first time in a water bath, connect the charging cable clamp, turn on the charger, and proceed according to process 1 in the table.

[0045] 3) When the eighth step of the formation is completed, the charged electricity reaches 126Ah, and the PbO2 content reaches about 81% at this time, the partial formation, that is, the conversion of basic lead sulfate and lead oxide is not complete. At this time, the battery capacity i...

Embodiment 3

[0059] Take 6-DZF-20 glue-sealed battery semi-finished products, and use the method of the present invention to add acid and chemically form. The sample preparation process is as follows:

[0060] 1) Add acid for the first time, add sulfuric acid solution with the first density of 1.28g / cm3 to the lead-acid battery to be added, the volume of acid addition is 155ml, and acid can be added in multiple times, the first time is 60ml, and the latter time is 95ml. Add acid by vacuum acid adding machine.

[0061] 2) Place the battery that has been acidified for the first time in a water bath, connect the charging cable clamp, turn on the charger, and proceed according to the process in Table 1.

[0062] 3) When the eighth step of the formation is completed, the charged electricity reaches 126Ah, and the PbO2 content reaches about 77% at this time, the partial formation, that is, the conversion of basic lead sulfate and lead oxide is not completed. At this time, the battery capacity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com