Tree stump removing device

A tree stump and bolt technology is applied in the field of tree stump removal devices, which can solve the problems of unstable clamping and easy shaking of tree stump removal devices, and achieve the effects of enhancing removal effect, improving stability and saving removal force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

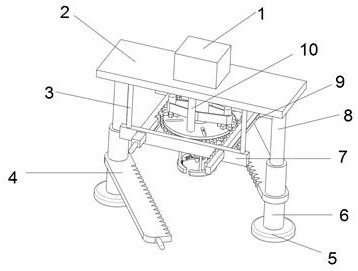

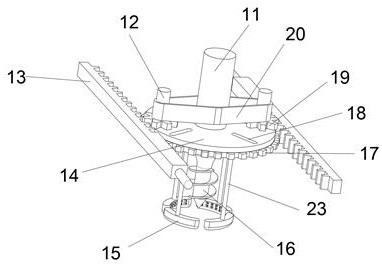

[0025] refer to Figure 1-3 , a tree stump removal device, comprising a support plate 2, a motor 1 is connected to the top outer wall of the support plate 2 by bolts, the motor 1 is fixed with a drilling mechanism, a lifting mechanism is fixed on the bottom outer wall of the support plate 2, and the bottom outer wall of the support plate 2 is connected by bolts There are two pillars 10, the bottom outer wall of the pillar two 10 is connected with a fixed circular plate 14 by bolts, the top of the fixed circular plate 14 is fixed with a linkage mechanism, the bottom outer wall of the fixed circular plate 14 is fixed with a clamping mechanism, and the bottom outer wall of the fixed circular plate 14 is connected by sliding There is a gear plate 17, and the outer wall of the bottom of the support plate 2 is fixed with a transmission mechanism.

[0026] In the present invention, the drilling mechanism includes a rotating shaft 11. The rotating shaft 11 and the output shaft of the ...

Embodiment 2

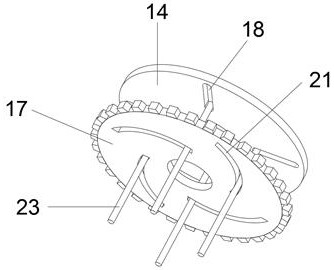

[0034] refer to Figure 2-4 , a tree stump removal device. Compared with Embodiment 1, the present embodiment includes a clamp ring 15. The clamp ring 15 is connected to the bottom outer wall of the sliding post 23 by bolts. Tooth 22, and the two sides of clamping helical tooth 22 are different with the included angle of clamp ring 15 one side, and the side outer wall that clamps helical tooth 22 and the included angle of one side of clamp ring 15 is connected with cutter tooth 24 by bolt.

[0035] During use, the clamping helical tooth 22 closely fits the tree stump when clamping, and the knife tooth 24 is located on the side with a large angle between the clamping helical tooth 22 and the clamp ring 15, and is opposite to the direction of rotation of the stud 16. When clamping the tree stump, Cutter teeth 24 are embedded in the stump, so that when clamping is more reliable, stud 16 is drilled into the stump to be more stable, which improves the stability of the clamping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com