An environmentally friendly sludge treatment equipment

An environmentally friendly technology for sludge treatment, applied in sludge treatment, water/sludge/sewage treatment, separation methods, etc., can solve sludge difficulties, waste of resources, landfill sludge easily occupies a large area of cultivated land, etc. problems, to achieve the effect of improving practicability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

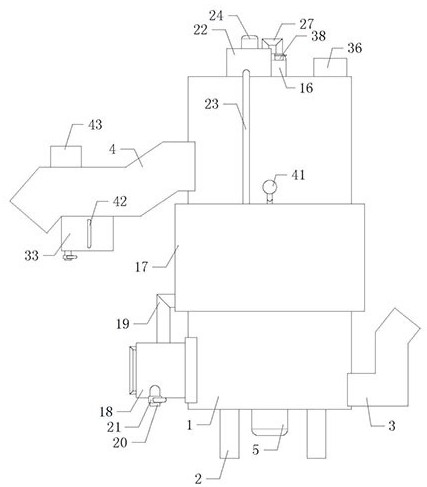

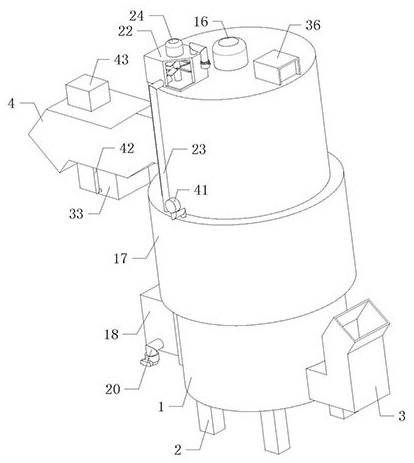

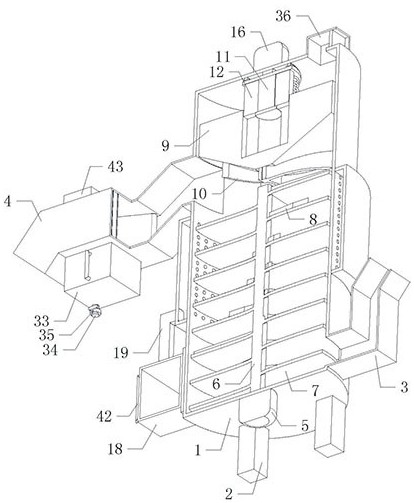

[0021] Such as Figure 1 to Figure 7 As shown, a kind of environment-friendly sludge processing equipment of the present invention, when it is working, open the first motor 5, the first motor 5 drives the pusher shaft 6 to rotate, and the pusher shaft 6 drives the screw pusher piece 7 and multiple groups The baffle plate 8 rotates, the second motor 16 is turned on, and the second motor 16 drives the power plate 14, the sliding shaft 11, two sets of synchronous plates 12 and the limit plate 13 to rotate, and the two sets of synchronous plates 12 drive the pressing material through two sets of synchronous slots The block 9 and the sets of arc-shaped pusher plates 10 on it r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com