Channel steel box girder composite girder bridge structure with built-in pipelines and construction method thereof

A technology of steel box girder and pipeline trough, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of affecting the appearance of bridges, long construction period, heavy bridges, etc., and achieve convenient construction, shorten construction period, and beautiful lines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

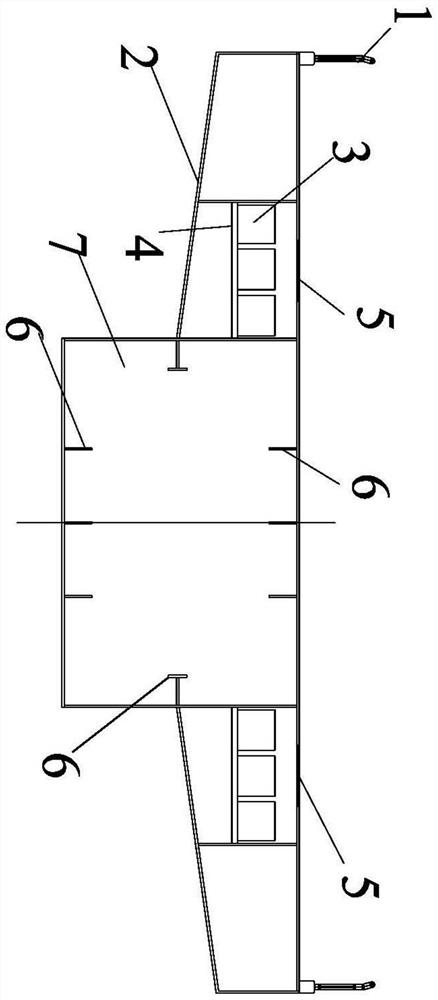

[0032] Such as Figure 1-2 As shown, when the steel box girder composite girder bridge structure is a pedestrian bridge, the flange parts 2 on both sides of the steel box girder 7 are divided into two regions, and the two regions are flanges divided in turn along the outward extension direction of the flange part 2 In order to ensure the torsional rigidity of the bridge, a diaphragm 8 is set at an interval of about 2m, and the diaphragm 8 is usually along the cross section of the bridge. Full cross-section layout, in the present invention, in order to leave space for the pipeline layout, the transverse partition 8 is arranged in the area other than the first flange area, and the horizontal and transverse cross braces 4 are installed in the first flange area, and the pipeline groove 3 is fixed on the horizontal Support 4 on.

[0033] In this embodiment, the cross brace 4 is made of I-shaped steel or channel steel, and the I-shaped steel or channel steel is provided with a slot...

Embodiment 2

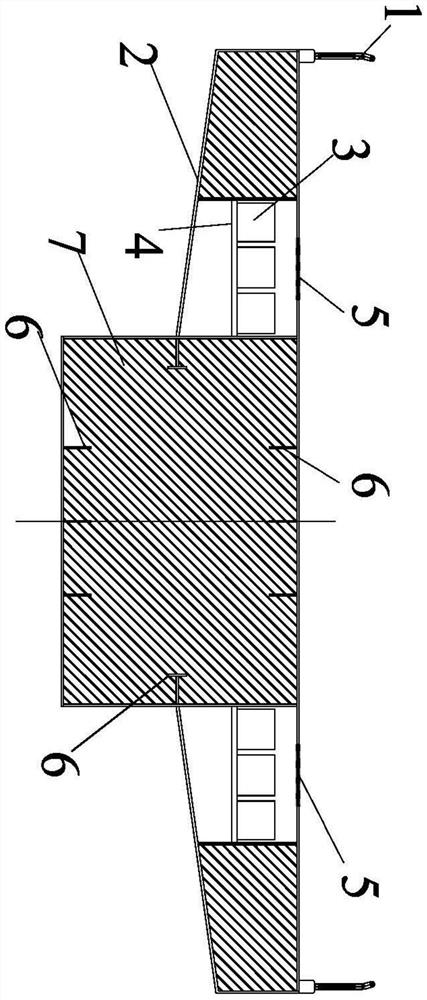

[0035] Such as Figure 3-4 As shown, when the steel box girder composite girder bridge structure is a pedestrian bridge, the flange parts 2 on both sides of the steel box girder 7 are divided into two regions, and the two regions are flanges divided in turn along the outward extension direction of the flange part 2 In order to ensure the torsional rigidity of the bridge, a diaphragm 8 is set at an interval of about 2m, and the diaphragm 8 is usually along the cross section of the bridge. Full cross-section arrangement, in the present invention, in order to leave space for the pipeline layout, the diaphragm 8 is arranged in the area other than the second area of the flange, the second area of the flange is installed with a horizontal and transverse cross brace 4, and the pipeline channel 3 is fixed on the horizontal Support 4 on.

[0036] In this embodiment, the cross brace 4 is made of I-shaped steel or channel steel, and the I-shaped steel or channel steel is provided wi...

Embodiment 3

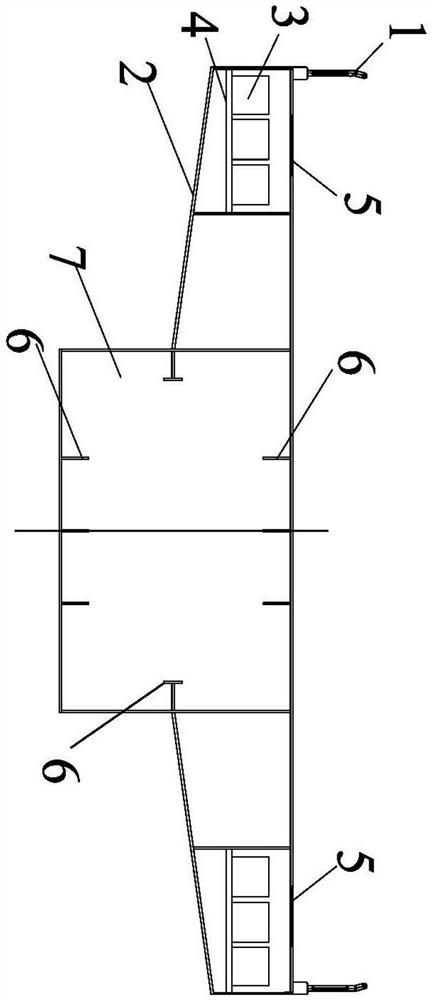

[0038] Such as Figure 5 As shown, when the steel box girder composite girder bridge structure is an urban steel bridge, the flange parts 2 on both sides of the steel box girder 7 are divided into two regions, and the two regions are the wings divided sequentially along the outward extension direction of the flange part 2. Between the first flange area and the second flange area, there is a partition between the first flange area and the second flange area; in order to ensure the torsional rigidity of the bridge, a transverse partition 8 is set at an interval of about 2m, and the transverse partition 8 is usually along the transverse direction of the bridge. The cross-section is arranged in full section. In the present invention, in order to leave space for the pipeline layout, the diaphragm 8 is arranged in the area other than the flange area. According to the maintenance and maintenance requirements, it is considered whether to set up a maintenance channel in the steel box. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com