A concrete railing column at the end of a bridge road with cast-in-place construction

A technology in concrete and concrete, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of inconvenient construction and installation on site, inconvenient prefabrication and transportation, poor structure, etc. The effect of transportation and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below in combination with specific embodiments.

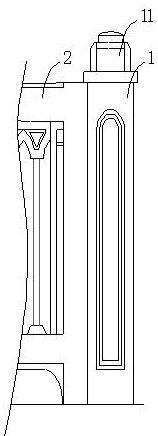

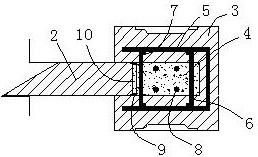

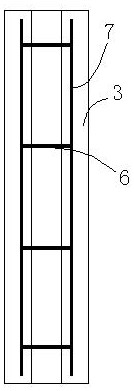

[0073] For specific implementation: see Figure 1-4 , a concrete railing column at the end of a bridge road for cast-in-place construction, including a column body 1, the lower end of which is fixed to the column installation positions at the outer edges of the road ends on both sides of the upper surface of the bridge, and the column body faces the side of the bridge A baffle 2 is fixedly arranged, and a column head 11 is also provided at the upper end of the column, wherein the column includes a vertically arranged panel part 3, and the panel part 3 has three outer sides and is used to form the front and rear sides and the front and rear sides of the column. On the side of the terminal, the inside of the panel has a cavity that opens away from the side of the terminal. The end of the baffle is sandwiched at the opening of the cavity and encloses a pouring space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com