Inclined hydraulic crushing pile driving equipment and construction process

A hydraulic crushing and tilting technology, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of hydraulic plate tilting, large plate impact, cumbersome construction work, etc., to reduce workload and reduce loss , Increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

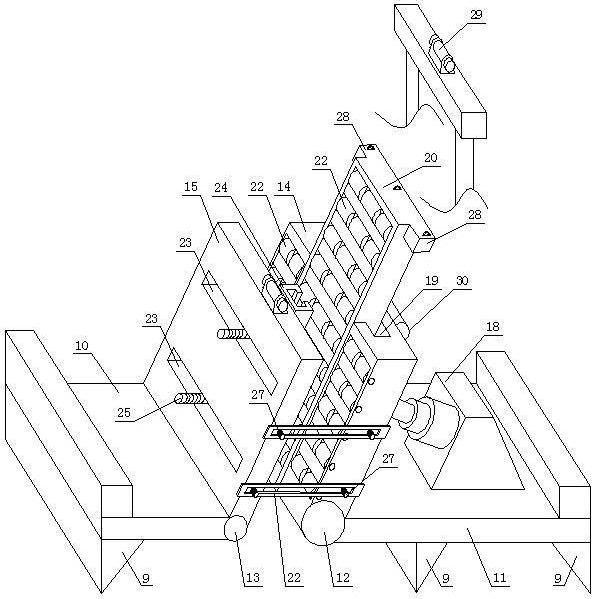

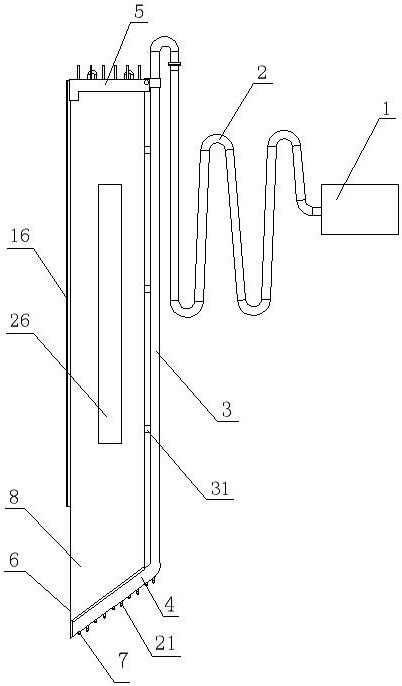

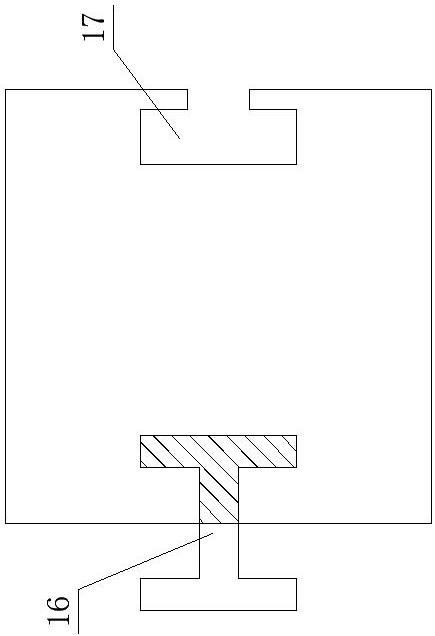

[0016] The inclined hydraulic crushing pile sinking equipment of the present invention is composed of a hydraulic inserting plate and a construction device. The outlet of the high-pressure water pump 1 is connected to the top inlet of the plate-shaped side wall water pipe 3 through the high-pressure water delivery hose 2, and the upper hook claw 5 is arranged on the top of the insert plate 8 to horizontally hinge the upper part of the plate-shaped side wall water pipe 3, I-beam I16 and chute I17 are respectively arranged on both sides, and more than one steel bar and lifting ring are fixed on the top. The I-beam I16 of two adjacent inserting plates 8 slides and fits with the chute I17, and more than one small slider 31 is fixed on the plate-shaped side wall water pipe 3 to slide and fit with the chute I17, and the bottom of the inserting plate 8 A groove is provided for sliding connection with the jet nozzle 4 with convex ribs on the upper part. The groove is provided with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com