An anti-fouling device covered with guardrail posts for road paving

A guardrail and road technology, applied in road safety devices, roads, roads, etc., can solve problems such as troublesome and inconvenient coverage, and achieve the effects of improving flexibility, stability, effectiveness, and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

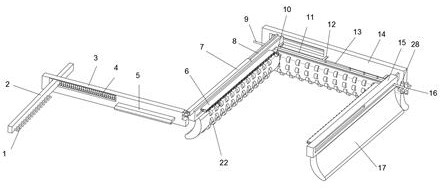

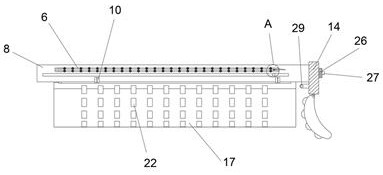

[0027] refer to Figure 1-3 and Figure 6 , a kind of guardrail post covering anti-scaling device for road laying, comprising a main board 14, the outer wall on one side of the main board 14 is connected with a fixed post 15 by bolts, the outer wall on one side of the main board 14 is slidably connected with a clamping sliding post 8, the main board 14, and the fixed post 15 The outer wall at the bottom of the clamped sliding column 8 is fixed with a positioning mechanism, the fixed column 15 and the outer wall on one side of the clamped sliding column 8 are fixed with a sliding mechanism, and the outer wall at the top of the clamped sliding column 8 is slidably connected with a slide bar 2 7, and the slide bar 2 7 is fixed with a clamping mechanism, and the outer wall of one side of the clamping sliding column 8 is connected to the limit sliding column 27 by bolts, and the limiting sliding column 27 is plugged into the inside of the main board 14, and the outer wall of the li...

Embodiment 2

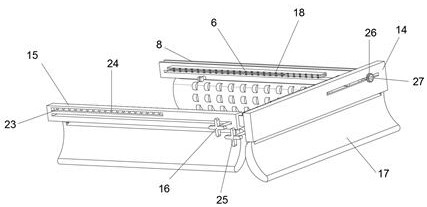

[0035] refer to Figure 3-5 , a guardrail column covering anti-scaling device for road paving. Compared with Example 1, the sliding mechanism of this embodiment includes a chute plate 6, and the chute plate 6 passes through the outer wall of the fixed column 15 and the clamping sliding column 8 respectively. Bolt connection, chute plate 6 one side outer wall is connected with rotating column one 18 by bearing, and rotating column one 18 is fixed with anti-skid mechanism, and fixed column 15 and clamping sliding column 8 one side outer walls are all connected with protective roller 10 by bolt.

[0036] In the present invention, the anti-slip mechanism includes a rubber splint 20, the rubber splint 20 is connected with the outer wall of the rotating column-18 by bolts, and a guide post 21 is inserted in the wall of the rotating column-18, between the guide post 21 and the inner wall of the rotating column-18 A pressure spring 19 is connected by bolts.

[0037] During use, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com