A whole-range adjustable resistance and yielding method for large deformation tunnels

A large deformation and roadway technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of increased difficulty in roadway support, inability to control pressure relief, small pressure relief space, etc., to reduce roadway expansion and support maintenance cost, improve the effect of pressure relief, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

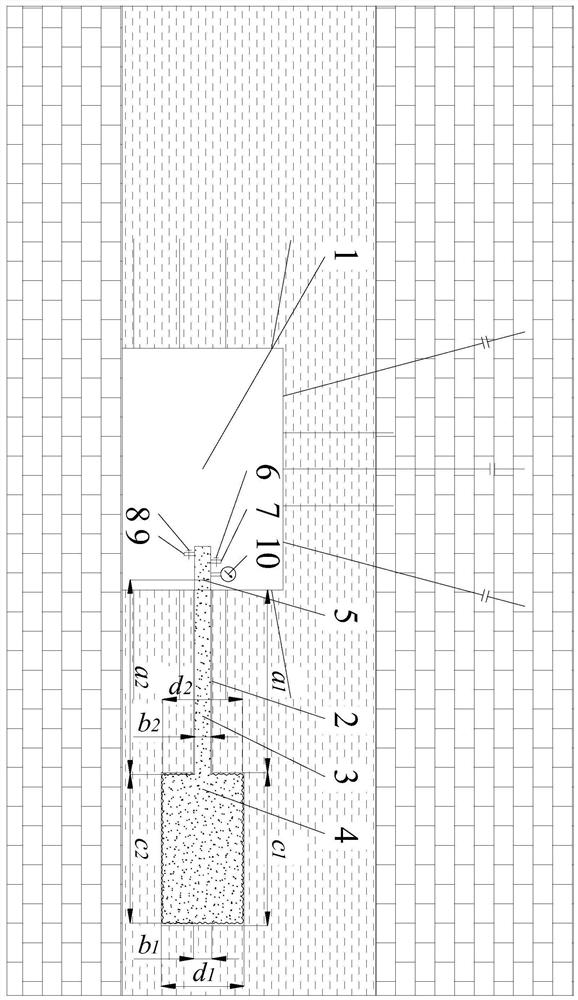

[0039] A roadway under the influence of deep high-stress soft rock or strong dynamic pressure with continuous large deformation Utilizes a method of fully adjustable resistance and yield pressure of a large deformation roadway of the present invention, such as figure 1 As shown in the figure, it can realize the whole process controlled pressure relief of the roadway under the influence of high stress soft rock or strong dynamic pressure.

[0040] When the deformation of the roadway gang is serious, the roadway gang pressure relief drilling should be arranged in the roadway gang. The specific implementation method and steps are as follows:

[0041] Step 1: Arrange roadside pressure relief boreholes 2 in deep soft rock or a gang of roadways affected by strong mining. After the construction of the ordinary section of roadside pressure relief boreholes 2 is completed, the end of the borehole is reamed to make the borehole The terminal forms a cylinder-like pressure relief space, a...

Embodiment 2

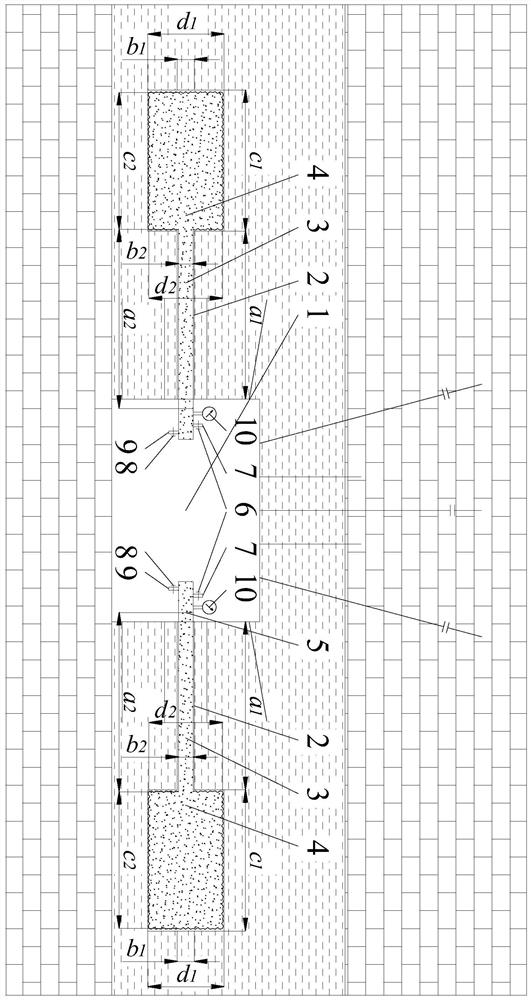

[0047] A deep high-stress soft rock or under the influence of strong dynamic pressure, the continuous large deformation of the two sides of the roadway uses the method of the present invention to adjust the full-range adjustable resistance and pressure of the large-deformation roadway, such as figure 2 As shown in the figure, it can realize the whole process controlled pressure relief of the roadway under the influence of high stress soft rock or strong dynamic pressure.

[0048] When the deformation of both sides of the roadway is serious, the roadway side pressure relief drilling should be arranged on the two sides of the roadway. The specific implementation method and steps are as follows:

[0049] Step 1: Arrange roadside pressure relief drilling 2 in deep soft rock or the two sides of the roadway affected by strong mining. The terminal forms a cylinder-like pressure relief space, and the length of the ordinary section is a 1 5m, diameter b 1 is 0.12m; length of reaming...

Embodiment 3

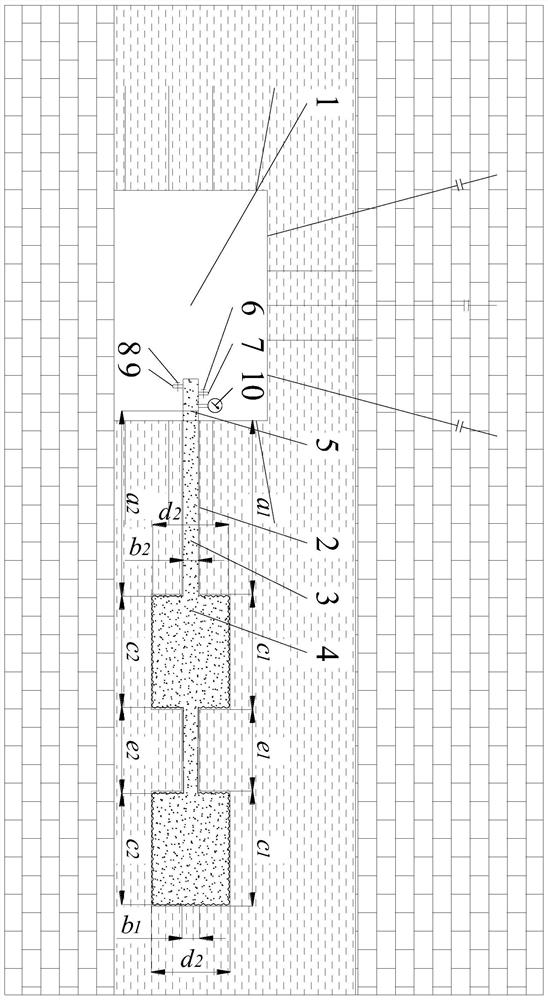

[0055] A deep high-stress soft rock or roadway under the influence of strong dynamic pressure is particularly serious if the continuous large deformation of the roadway is particularly serious. A method of fully adjustable resistance and yielding pressure of a large deformation roadway according to the present invention, such as image 3 As shown in the figure, it can realize the whole process controlled pressure relief of the roadway under the influence of high stress soft rock or strong dynamic pressure.

[0056] When the deformation of a gang of roadways is particularly serious, and a single pressure relief space in a gang of roadway pressure relief boreholes cannot meet the pressure relief needs, multiple pressure relief spaces are arranged in a gang of roadway pressure relief boreholes. The specific implementation methods and steps are as follows: :

[0057] Step 1: Arrange the roadside pressure relief drilling 2 in the side of the roadway affected by deep soft rock or st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com