Raise boring machine-medium-length hole millisecond blasting cooperative one-time grooving method

A technology of raise drilling rig and differential blasting, which is applied in the direction of discharge machinery, earthwork drilling and mining, mining equipment, etc. It can solve the problems of poor construction safety of upward holes, increased blasting safety risks, and increased construction period, so as to achieve flexible construction , reduce blasting hazards, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

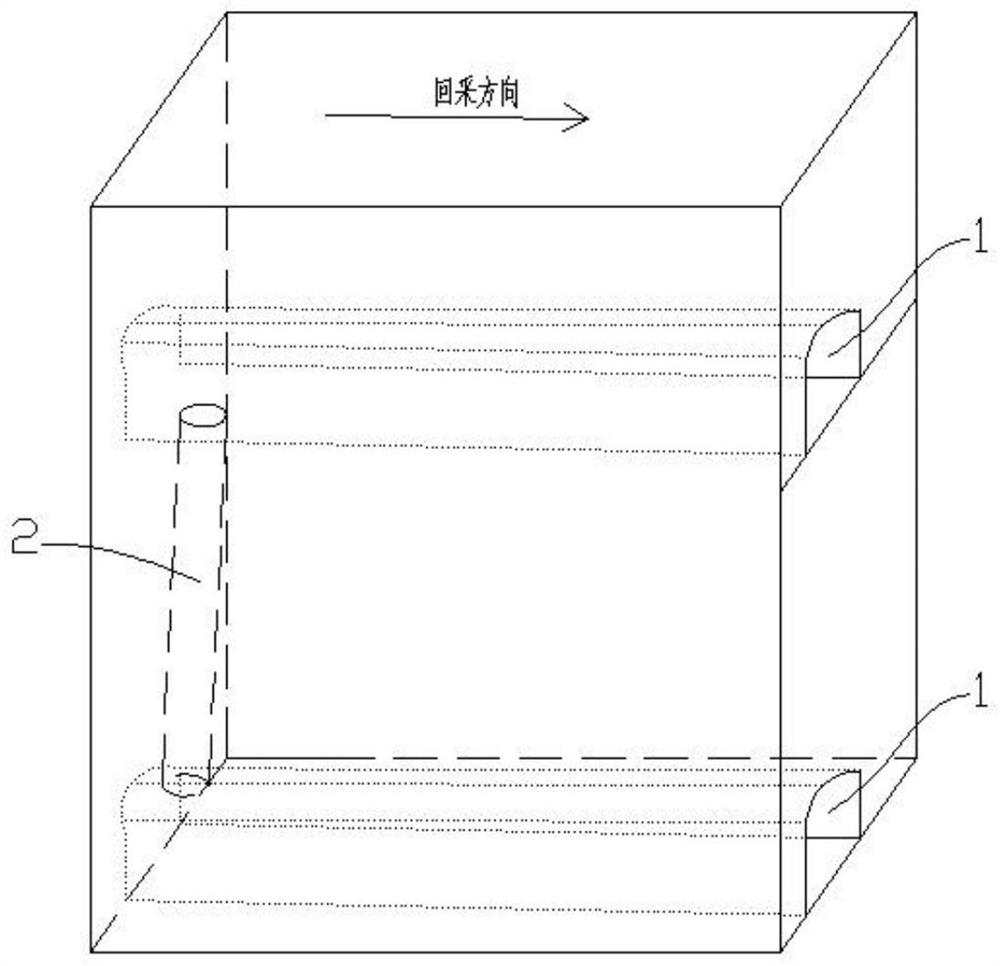

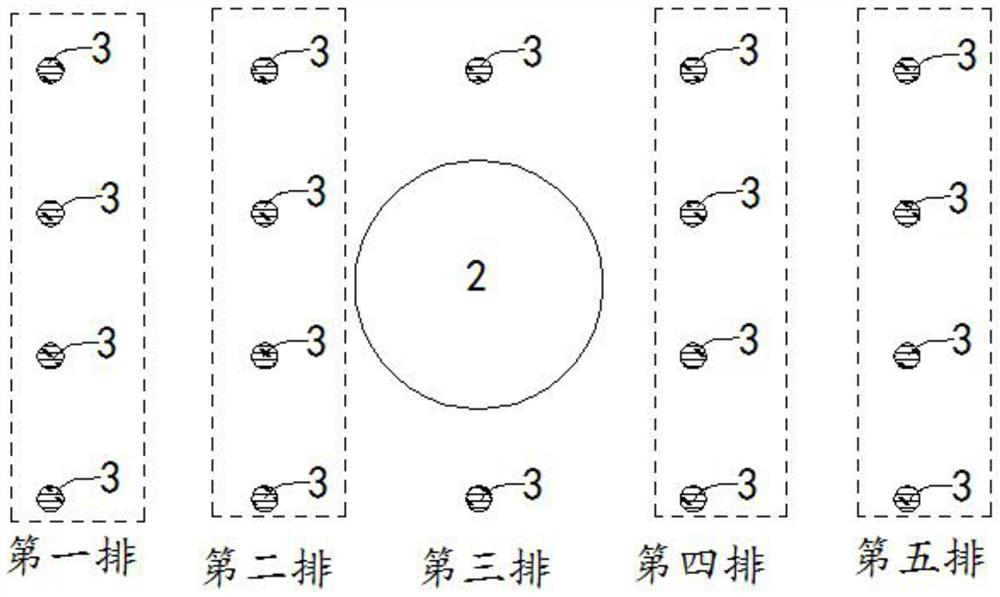

[0051] Implementation background: The first mining area of a certain phosphate rock is a steeply inclined medium-thick deposit, with an ore body dip angle of 51°-82°, with an average of 71°. 60m, middle section height 60m, section height 15m, mine room length 60m, no inter-column, top-bottom column, using raise drilling rig-medium-deep hole differential blasting combined one-time trough forming method, the number of troughs is 79, the specific The construction steps are as follows:

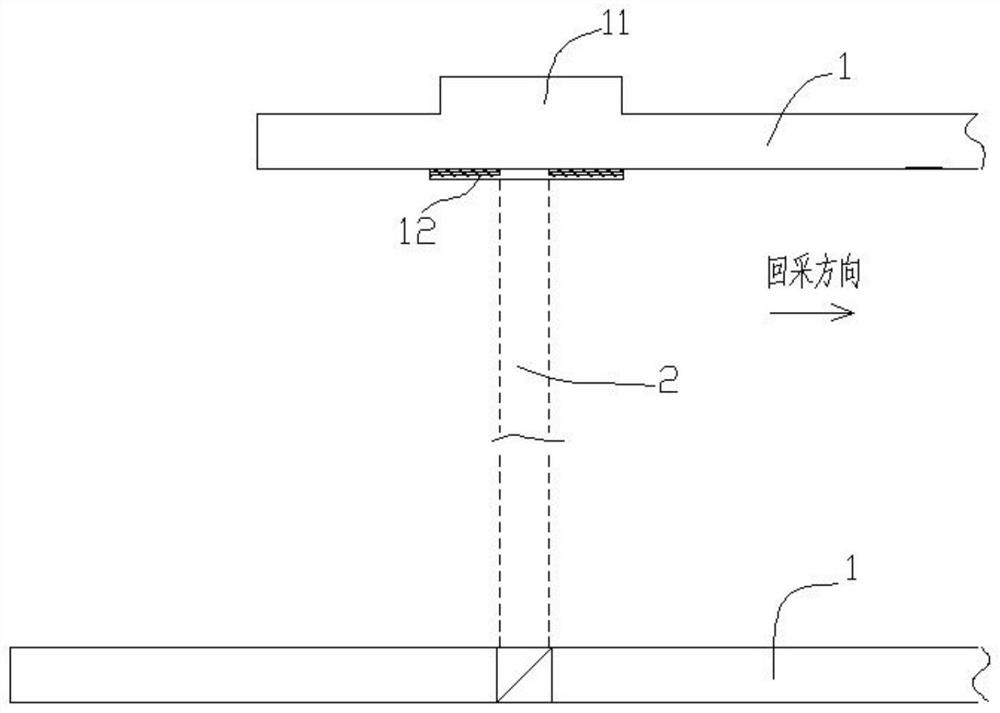

[0052] (1) Based on the stope conditions, excavate a construction chamber in the upper cutting drift, the floor of the construction chamber should be flat and free of turquoise scum; pour a concrete base in the middle of the hole so that it is located on the bedrock surface, Its size is 5.3m in length, 2.5m in width, and 300mm in thickness, its compressive capacity is not less than 240T, and its tensile capacity is not less than 30T;

[0053] (2) Install the raise drilling rig on the concrete b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com