Active and pile-slab combined tunnel supporting system for karst cave group crossing and construction method

A technology of combined support and karst caves, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of many hidden karst caves, great difficulty, and high construction risks, and achieve the goals of reducing excavation volume, ensuring bearing capacity, and reducing risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

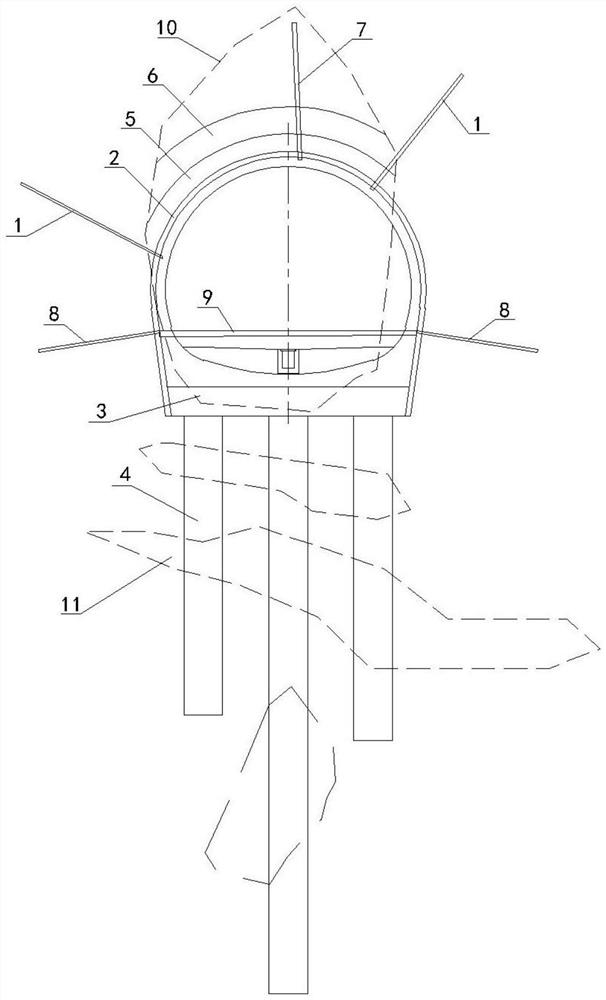

[0026] see figure 1 In this embodiment, the active support and pile-slab joint system of tunnels passing through the karst cave group is a joint support and bearing system formed by anchor cables and pile slabs, including:

[0027] The steel arch 2 in the primary support structure is located below the karst cave 10 in the arch; the front end of the anchor cable 1 is anchored in the rock mass of the arch, the tail of the anchor cable 1 is fixedly welded on the steel arch 2, and the anchor cable 1 runs along the steel arch 2. There are many arched sides of the arch frame 2, and the steel arch frame 2 is actively supported by the anchor cable 1; the locking foot anchor pipe 8 is set at the arch foot, and the transverse temporary inverted arch 9 is set to form the primary support structure .

[0028] A pile foundation 4 is set for the hidden karst cave 11 at the bottom, and a pile foundation group is formed by a plurality of pile foundations 4 in the area where the hidden karst c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com