Multi-surface-supporting welded exhaust hood of industrial steam turbine

An industrial steam turbine and steam exhaust cylinder technology, which is applied in the field of steam turbine exhaust cylinders, can solve problems such as increased vibration of the rotating shaft, deformation of the joint of the blade rotating shaft, and reduced safety and stability of the steam turbine, achieving the goal of reducing vibration and improving safety and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

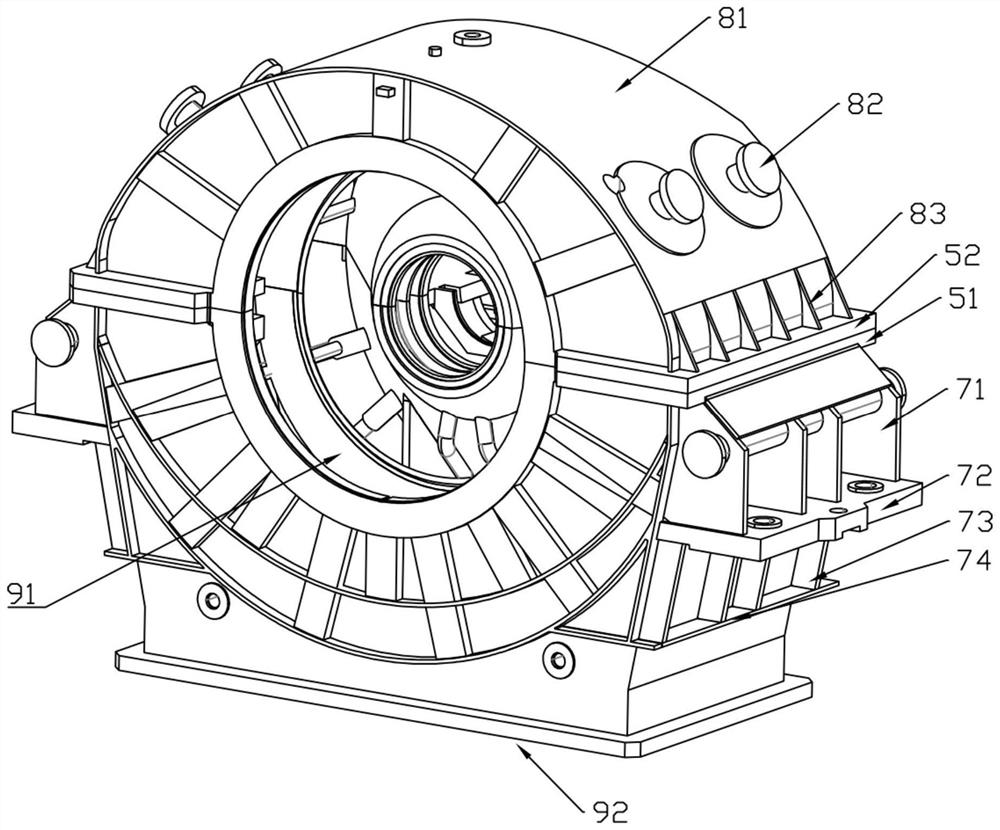

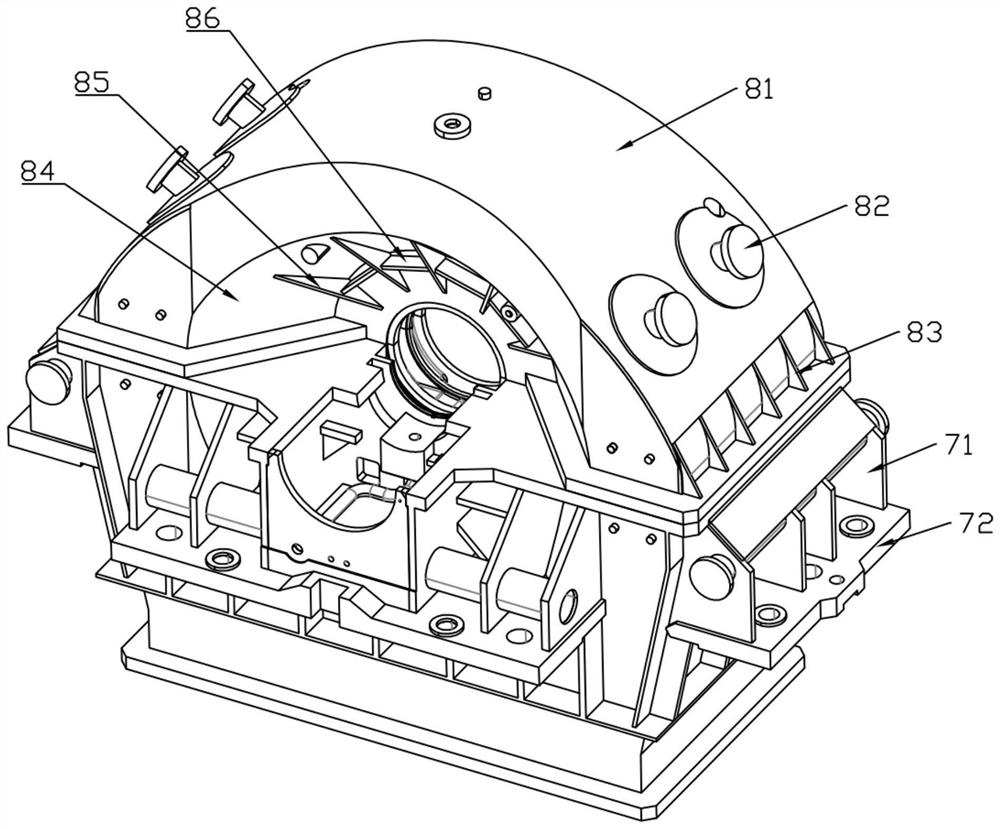

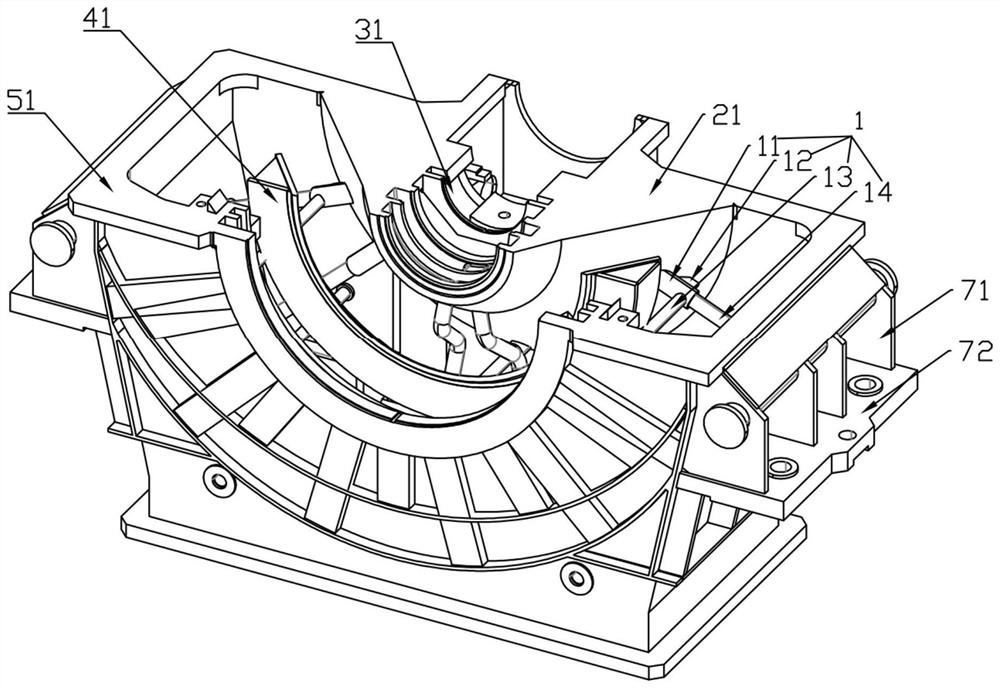

[0024] like figure 1 , 3 As shown, a welded exhaust cylinder of an industrial steam turbine supported by multiple surfaces includes an upper part of the exhaust cylinder and a lower part of the exhaust cylinder. A rod support assembly 1 is fixed on the diffuser inner guide ring 21. The rod support assembly 1 includes a sleeve rod 11, a first cross bar 14, a second cross bar 13 and an abutment plate 12. One end of the sleeve rod 11 is connected to the diffuser. The arc side of the inner guide ring 21 is fixedly connected, the other end of the sleeve rod 11 is connected to one end of the first cross bar 14, and the end of the first cross bar 14 not connected to the sleeve rod 11 is fixedly connected to the inner side wall of the lower part of the exhaust cylinder. One end of the second cross bar 13 is fixedly connected to the arc side of the sleeve rod 11, the other end of the second cross bar 13 is fixedly connected to the inner front wall of the lower part of the exhaust cyli...

Embodiment 2

[0030] The center of circle of the lower bottom surface of the diffuser inner guide ring 21 is set as the origin, and the ray where the diameter of the lower bottom surface of the diffuser inner guide ring 21 is parallel to the horizontal line is set as the x-axis, and the inner guide ring 21 of the diffuser is The ray where the diameter of the lower bottom surface is perpendicular to the x-axis is set as the y-axis, the ray where the central axis of the diffuser inner guide ring 21 is located is set as the z-axis, and the first crossbar 14 is respectively connected to the x-axis, y-axis and z-axis The acute angles formed are 20°~30°, 70°~80° and 65°~75°; the acute angles formed by the second cross bar 13 with the x-axis, y-axis and z-axis respectively are 85°-90°, 0 °~5° and 85°~90°. The direction in which the connecting part of the sleeve rod 11 and the diffuser inner guide ring 21 receives the force from the connecting part of the blade shaft is the tangential direction of ...

Embodiment 3

[0032] The sleeve rod 11 is provided with a first mass chamber, the first mass chamber is filled with liquid, one end of the first cross bar 14 is set in the first mass chamber and has an interference fit with the first mass chamber, and the lower part of the exhaust cylinder A second mass cavity is provided in the front wall, and one end of the second crossbar 13 is disposed in the second mass cavity and is interference fit with the second mass cavity. When the exhaust steam displacement is large, the temperature of the exhaust cylinder rises, and the liquid in the first volume chamber expands. The first cross bar 14 no longer can only passively provide support force, but can also actively provide support for the lower exhaust cylinder. The driving force further reduces the deformation of the connecting part of the blade shaft. Similarly, the liquid in the second volume cavity also expands, and the second crossbar 13 provides supporting force and driving force for the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com