A time-domain test and analysis method for dynamic parameters of automotive fluid pumps

A technology of dynamic parameters, test and analysis, applied in pump test, machine/engine, liquid variable capacity machinery, etc., can solve the problem of signal time domain mismatch and achieve the effect of improving evaluation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

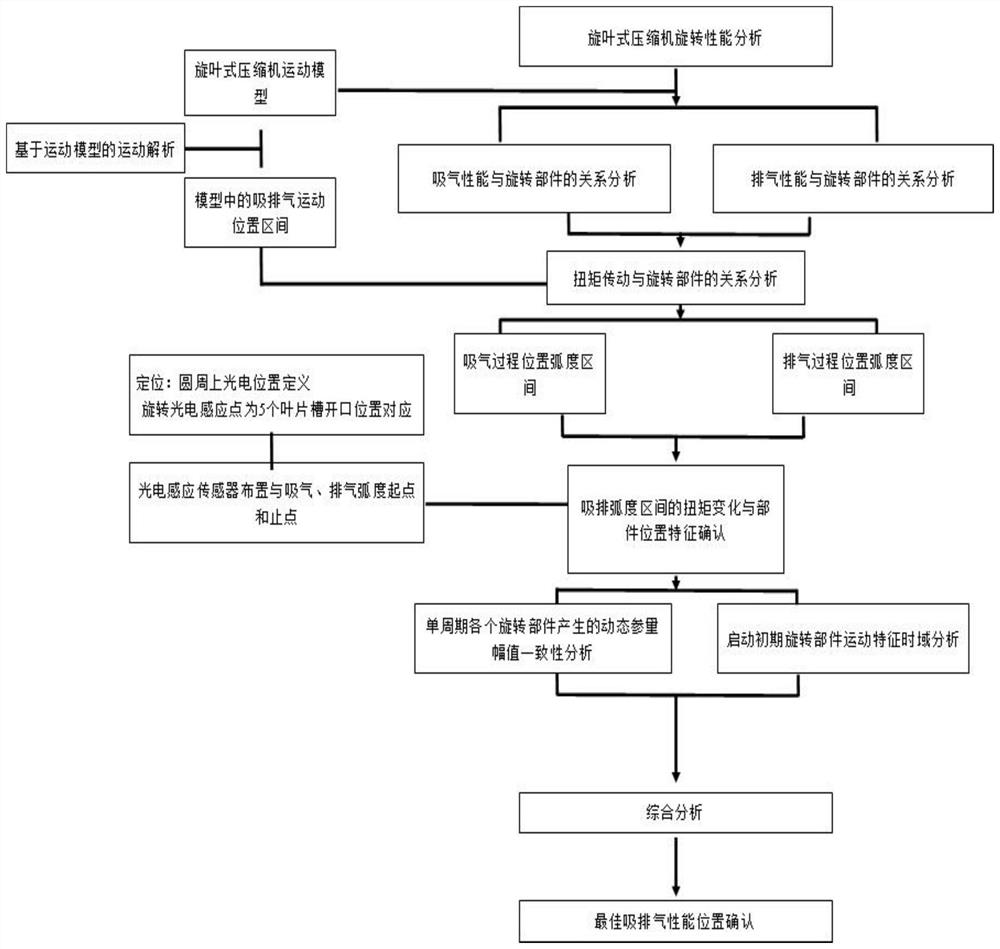

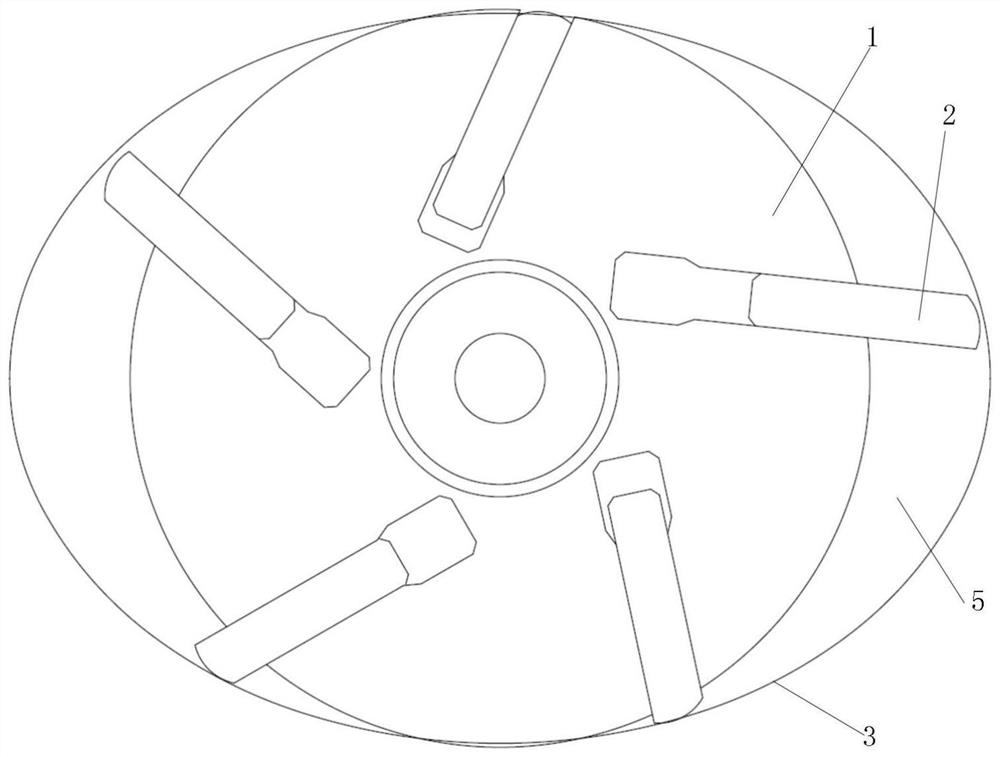

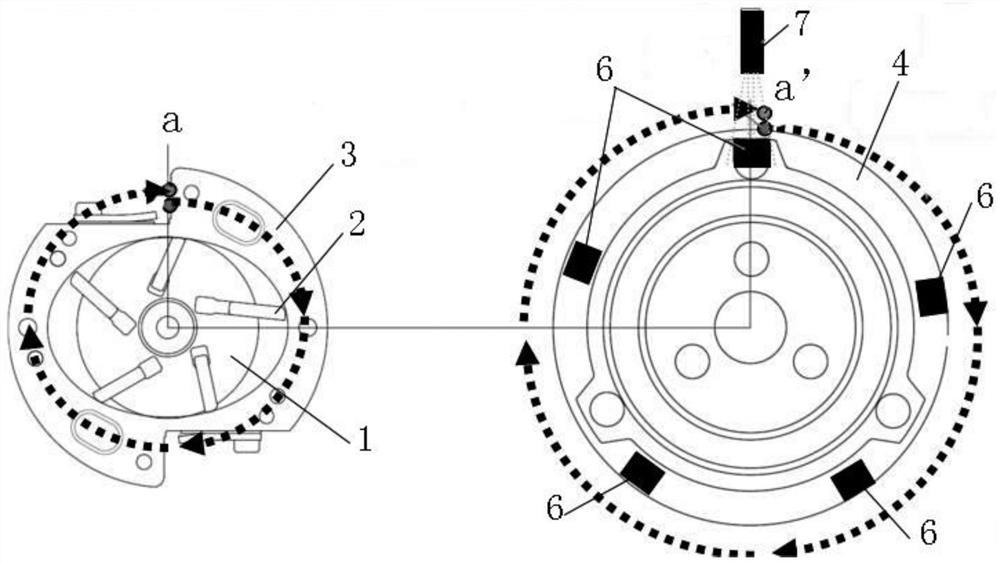

[0049] Below in conjunction with accompanying drawing, the present invention will be further described, see figure 1 , figure 2 , Figure 9 , a time-domain test and analysis method for dynamic parameters of an automotive fluid pump. The fluid pump includes a rotor 1, blades 2, cylinder 3, and a clutch armature 4 and a pulley 8 connected to the long axis of the rotor. The pump has a compression chamber 5.

[0050] In order to clarify the technical solution of the present invention accurately, the present invention selects the rotary vane automobile air-conditioning compressor as the characteristic model of the dynamic parameter time domain test method of the automobile fluid pump;

[0051] The rotary structure of the rotary vane compressor is composed of a rotor 1, five blades 2, an elliptical line cylinder body 3, front and rear end plates, a clutch armature 4 connected to the long axis of the rotor, and a pulley 8.

[0052] Such as figure 2 , Figure 4 As shown, the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com