Industrial water-cooled water chiller

An industrial water and chiller technology, applied in refrigerators, refrigeration components, mechanical equipment, etc., can solve problems such as vibration, whistling, whistling of valve core moving parts, etc., to increase the natural frequency, simple structure, good quality Using the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

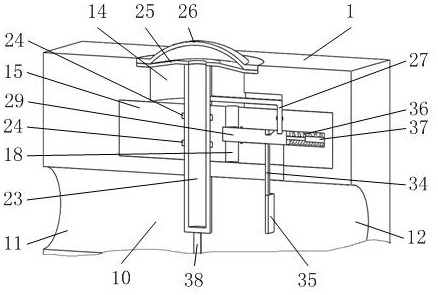

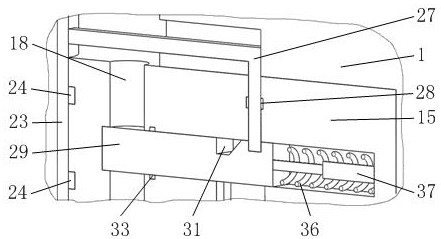

[0038] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

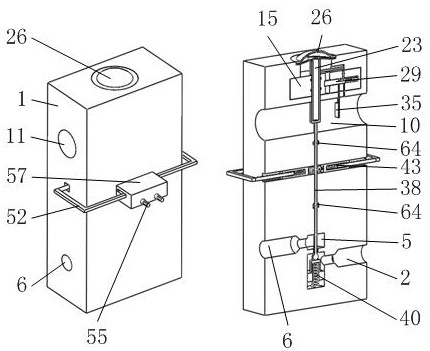

[0039] Such as figure 1 As shown, it includes a refrigeration cycle, a condenser water cooling heat dissipation cycle, and an evaporator cold water control cycle. It is characterized in that: the thermal expansion valve in the refrigeration cycle includes a valve housing 1, a fixed block 15, a push rod A23, a diaphragm 25, and a sealing cover 26. Limit rod 27, slider 29, connecting rod 34, spoiler 35, spring A36, damping rod 37, ejector rod B38, ball head 39, spring B40, telescopic rod 43, spring C48, U seat 49, pressure Wheel 50, L rack 52, gear A53, worm wheel 54, worm screw 55, transmission shell A57, adjustment tool 58, wherein as figure 1 , 2 As shown in , 15, a fixing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com